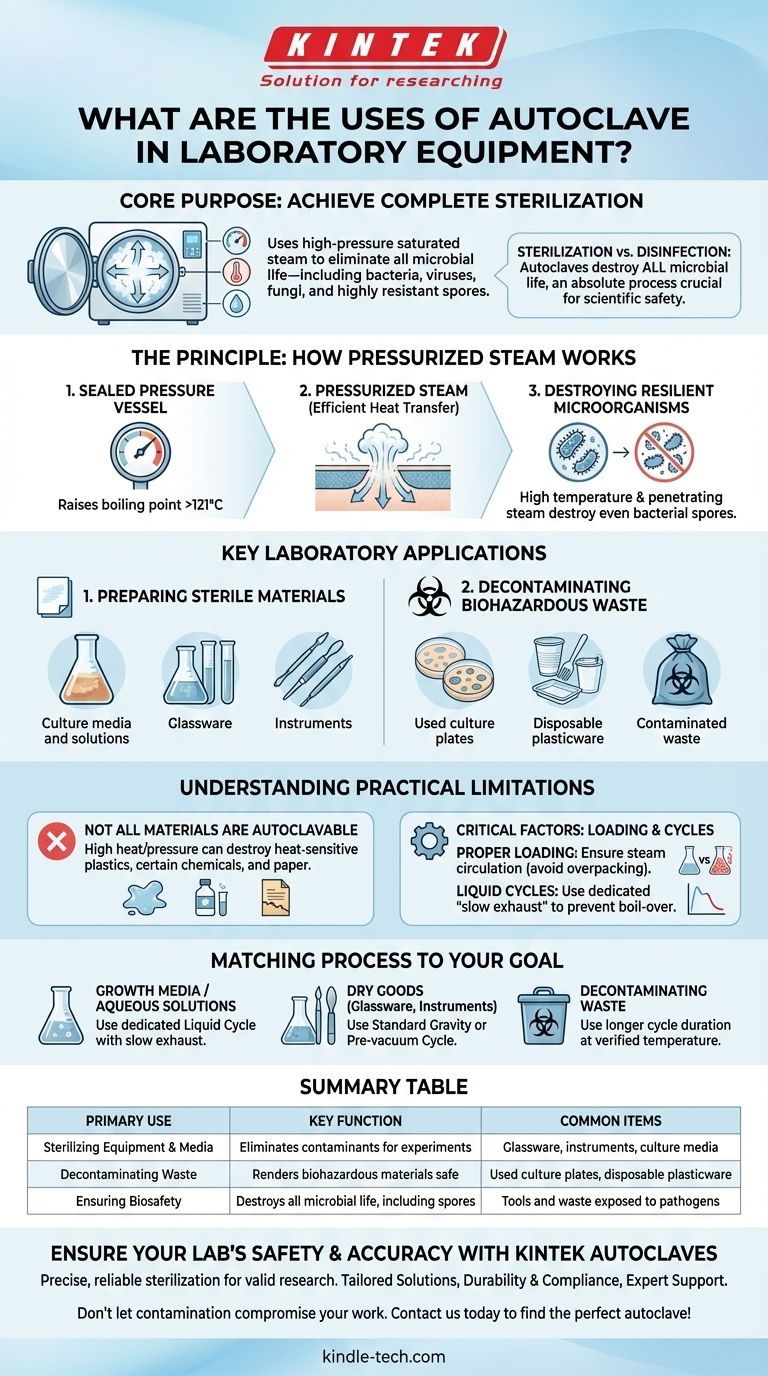

At its core, the primary use of an autoclave in a laboratory is to achieve complete sterilization. It uses high-pressure saturated steam to eliminate all forms of microbial life—including bacteria, viruses, fungi, and highly resistant spores—from lab equipment, liquids, and waste materials. This process is absolutely critical for preventing experimental contamination and ensuring biological safety.

The crucial distinction to understand is that an autoclave provides sterilization, not just disinfection. While disinfection reduces harmful microorganisms, sterilization is an absolute process that destroys all microbial life, which is non-negotiable for most scientific and medical applications.

The Principle: How Pressurized Steam Achieves Sterility

Before listing its uses, it's essential to understand why an autoclave is so effective. Its power comes from a combination of heat, pressure, and moisture.

The Role of Pressurized Steam

An autoclave is a sealed pressure vessel. By increasing the pressure, it raises the boiling point of water far above 100°C (212°F).

This pressurized steam is a highly efficient agent for transferring heat. The moisture rapidly penetrates materials and denatures the essential proteins and enzymes that make up microorganisms, killing them completely.

Destroying Resilient Microorganisms

Simple boiling water or detergents cannot eliminate the most durable forms of life, such as bacterial spores.

The high temperatures (typically 121°C or higher) and penetrating steam inside an autoclave are specifically designed to destroy these resilient organisms, ensuring true sterility.

Key Laboratory Applications

In a lab setting, an autoclave's uses can be grouped into two main categories: preparing sterile materials for experiments and decontaminating hazardous materials afterward.

Preparing Sterile Equipment and Reagents

The most frequent use is preparing a clean slate for research. This prevents unwanted microbes from interfering with experimental results.

Commonly sterilized items include:

- Culture media and solutions: Ensuring that growth media is free of contaminants before introducing a specific microorganism.

- Glassware: Sterilizing flasks, beakers, and test tubes.

- Instruments: Sterilizing metal surgical tools or heat-resistant plastic items like pipette tips and centrifuge tubes.

Decontaminating Biohazardous Waste

Before disposal, any material that has come into contact with microorganisms must be rendered safe. This is a critical biosafety function.

Autoclaves are used to decontaminate used culture plates, disposable plasticware, and any other waste contaminated with bacteria, viruses, or other biological material.

Understanding the Practical Limitations

While powerful, an autoclave is not a universal solution. Misuse can lead to incomplete sterilization, damaged equipment, or safety hazards.

Not All Materials Can Be Autoclaved

The high heat and pressure will destroy many common materials.

Heat-sensitive plastics will melt, certain chemicals can release toxic fumes, and items like paper can degrade. Always verify that an item is marked as autoclavable.

Proper Loading is Critical

Steam must be able to circulate freely and penetrate every surface of the items being sterilized.

Overpacking the chamber or using improper containers can create air pockets that prevent steam from reaching all surfaces, resulting in a failed sterilization cycle.

Liquids Require a Specific Cycle

Liquids must be processed on a dedicated "liquid cycle" that cools down slowly.

Using a standard (fast exhaust) cycle will cause the liquids to boil violently and spill over, creating a mess and a significant safety risk.

Matching the Process to Your Goal

To use an autoclave effectively, you must select the correct procedure for the material you are handling.

- If your primary focus is preparing growth media or aqueous solutions: Use a dedicated liquid cycle with a slow exhaust to prevent boil-over and ensure thorough sterility without volume loss.

- If your primary focus is sterilizing dry goods like glassware or instruments: A standard gravity or pre-vacuum cycle is ideal for ensuring rapid and complete steam penetration.

- If your primary focus is decontaminating biohazardous waste: Use a longer cycle duration at a verified temperature to guarantee the complete inactivation of all potentially dangerous pathogens.

Mastering the autoclave is fundamental to ensuring the integrity, safety, and reproducibility of your work.

Summary Table:

| Primary Use | Key Function | Common Items |

|---|---|---|

| Sterilizing Equipment & Media | Eliminates contaminants for experiments | Glassware, instruments, culture media |

| Decontaminating Waste | Renders biohazardous materials safe | Used culture plates, disposable plasticware |

| Ensuring Biosafety | Destroys all microbial life, including spores | Tools and waste exposed to pathogens |

Ensure Your Lab's Safety and Accuracy with KINTEK Autoclaves

Precise, reliable sterilization is non-negotiable for valid research results and safe laboratory operations. At KINTEK, we specialize in high-performance autoclaves designed to meet the rigorous demands of modern laboratories. Whether you need to sterilize sensitive culture media, decontaminate hazardous waste, or maintain sterile instruments, our solutions deliver consistent, verified results.

Why Choose KINTEK?

- Tailored Solutions: We provide autoclaves with specific cycles for liquids, dry goods, and biohazardous materials.

- Durability & Compliance: Our equipment is built to last and meets stringent safety standards.

- Expert Support: From selection to maintenance, our team ensures your autoclave operates flawlessly.

Don’t let contamination compromise your work. Contact us today to find the perfect autoclave for your laboratory’s unique needs!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- Why is the standard autoclave temperature set to 121? The Science of Effective Sterilization

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing