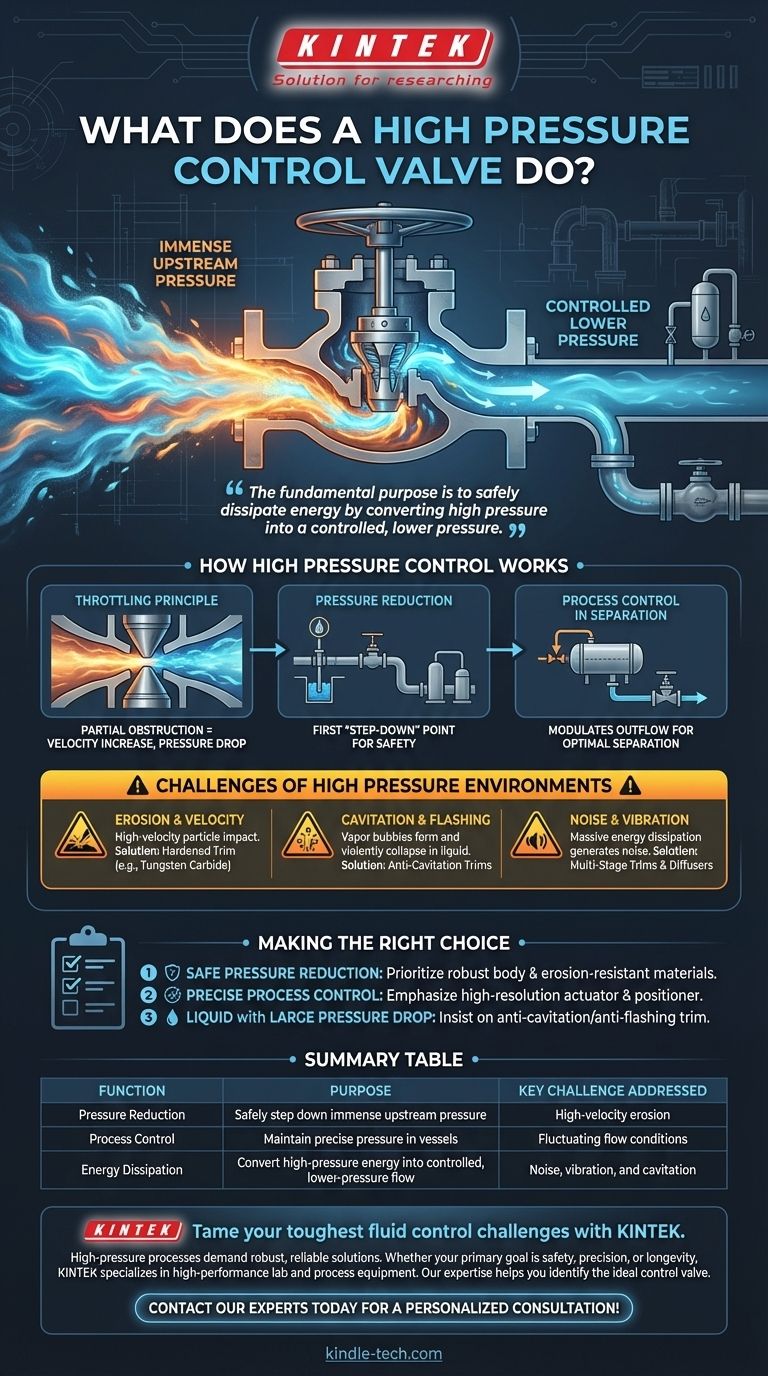

At its core, a high pressure control valve is a specialized industrial tool designed to precisely manage the flow and pressure of fluids in extreme environments. It is not an on/off switch, but rather a sophisticated throttling device. It creates a calculated restriction in a pipeline to safely reduce immense upstream pressure to a lower, more manageable level required for downstream processes.

The fundamental purpose of a high pressure control valve is to safely dissipate energy. It achieves this by converting the high pressure of a fluid into a controlled, lower pressure, making it an essential component for both safety and process optimization in demanding industries.

How High Pressure Control Works

A standard valve is often designed for simple isolation (on/off). A high pressure control valve, however, is built for the punishing task of continuous regulation under immense force, a process known as throttling.

The Principle of Throttling

Throttling is the act of intentionally creating a partial obstruction in the flow path. As fluid is forced through this smaller opening, its velocity increases, but its pressure drops significantly. The valve's internal components, collectively called the trim, are engineered to withstand the extreme velocity and turbulence this pressure drop creates.

Key Application: Pressure Reduction

The most common use is straightforward pressure reduction. Upstream energy sources, like oil and gas wellheads, often have pressures that are far too high for standard processing equipment, separators, or pipelines. A high pressure control valve acts as the first "step-down" point, ensuring the rest of the system receives fluid at a safe and usable pressure.

Key Application: Process Control in Separation

In processes like fluid separation, maintaining a specific, stable pressure inside a vessel is critical. This pressure dictates how efficiently oil, gas, and water will separate from each other. A high pressure control valve on the outlet of the separator modulates the outflow to hold the vessel pressure at the exact setpoint required for optimal performance.

The Challenges of High Pressure Environments

Managing high pressure differentials introduces destructive physical phenomena that standard valves are not designed to handle. The design of a high pressure valve is a direct response to these challenges.

Combating Erosion and Velocity

When pressure drops dramatically, fluid velocity can become extremely high, turning particles within the fluid into projectiles that sandblast the valve's internals. High pressure valves use hardened trim materials (like tungsten carbide) and specially designed flow paths to minimize the impact of this erosion.

Preventing Cavitation and Flashing

In liquid service, a severe pressure drop can cause the liquid's pressure to fall below its vapor point, causing vapor bubbles to form (flashing). If the pressure then recovers downstream, these bubbles violently collapse (cavitation), creating micro-jets that can destroy metal components. Specialized anti-cavitation trims are used to prevent this damage.

Managing Noise and Vibration

The massive energy dissipation that occurs during a large pressure drop generates significant noise and mechanical vibration. This is not just a nuisance; it can damage the valve, the actuator, and surrounding piping. High pressure valves often incorporate multi-stage trims or diffusers to break the single large pressure drop into a series of smaller, quieter ones.

Making the Right Choice for Your Goal

Selecting the correct valve requires understanding your primary objective, as the design must be matched to the specific demands of the service.

- If your primary focus is safe pressure reduction: Prioritize valves with robust body construction and hardened trim materials designed to resist high-velocity erosion over a long service life.

- If your primary focus is precise process control: Emphasize the actuator and positioner package, ensuring it has the resolution and responsiveness to maintain a stable setpoint under fluctuating conditions.

- If you are handling a liquid with a large pressure drop: Insist on a valve with an anti-cavitation or anti-flashing trim to guarantee the mechanical integrity of your system.

Ultimately, a high pressure control valve is an engineered solution for taming the immense energy stored in pressurized fluids.

Summary Table:

| Function | Purpose | Key Challenge Addressed |

|---|---|---|

| Pressure Reduction | Safely step down immense upstream pressure for downstream equipment. | High-velocity erosion. |

| Process Control | Maintain precise pressure in vessels (e.g., separators) for optimal performance. | Fluctuating flow conditions. |

| Energy Dissipation | Convert high-pressure energy into controlled, lower-pressure flow. | Noise, vibration, and cavitation. |

Tame your toughest fluid control challenges with KINTEK.

High-pressure processes demand robust, reliable solutions. Whether your primary goal is safe pressure reduction, precise process control, or preventing cavitation damage, selecting the right valve is critical.

KINTEK specializes in providing high-performance lab and process equipment. Our expertise can help you identify the ideal high-pressure control valve with the right trim, materials, and actuation for your specific application—ensuring safety, longevity, and peak efficiency.

Let's optimize your process together. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Air Valve Applications

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Round Bidirectional Press Mold for Lab

- Cylindrical Press Mold with Scale for Lab

- Special Shape Press Mold for Lab

People Also Ask

- What role does a high-vacuum reactor play in Ti-Al-Y alloy synthesis? Master High-Temperature Hydride Processing

- What is the function of a pre-filled alumina powder layer in an SHS reactor? Protect Your Sensitive Lab Instrumentation

- What role does hydrothermal synthesis in high-pressure reactors play in molecular sieve catalyst preparation?

- What is the role of a high-pressure hydrothermal reactor in the preparation of POMs@ZIF-67 precursors?

- What is the function of a high-precision temperature-controlled reactor in the synthesis of bio-based benzoxazine monomers?

- What role does a laboratory temperature-controlled reactor play in biological corrosion simulation experiments? - KINTEK

- Why are reactors with anchor agitators and heat exchange jackets needed for metal oxide nanopowders? Achieve Uniformity

- What is the principle of pyrolysis reactor? Harness Heat Without Oxygen to Convert Waste into Value