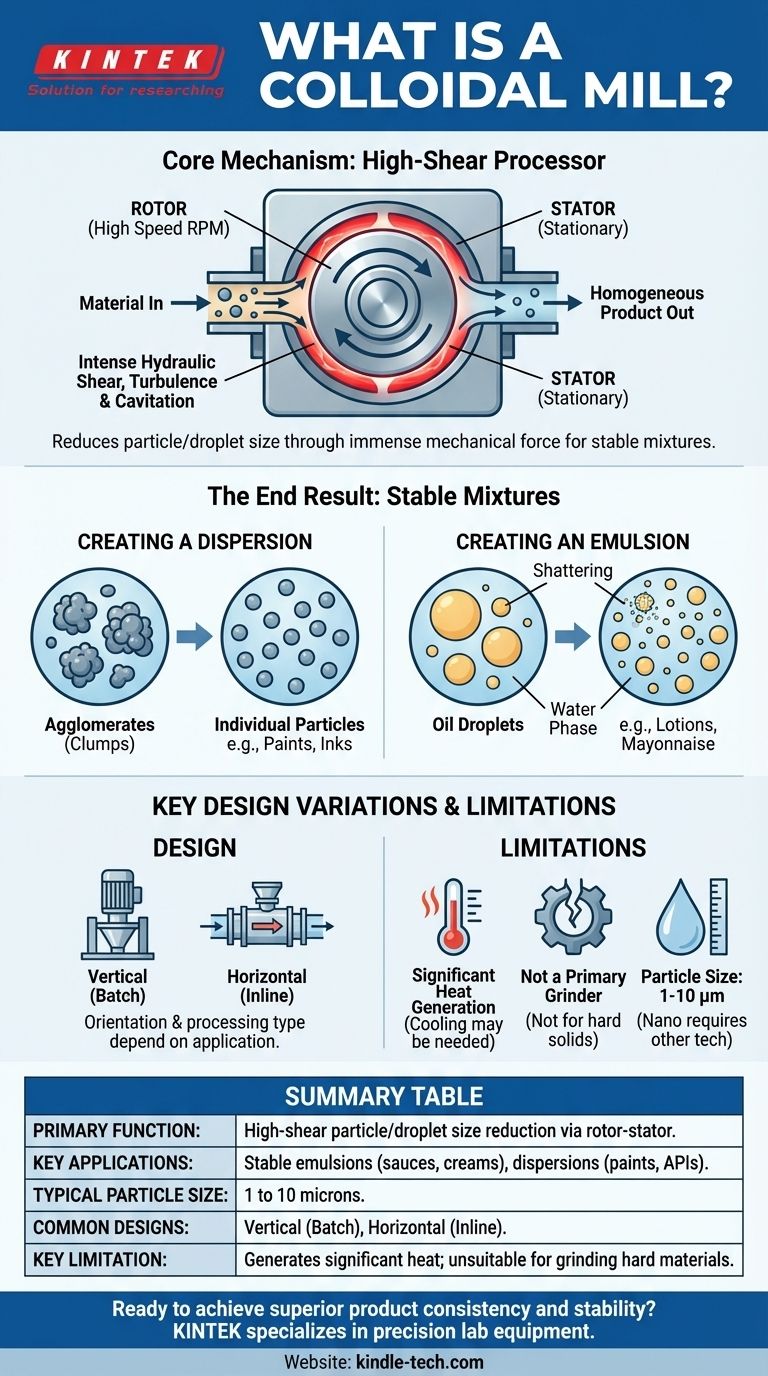

In essence, a colloidal mill is a high-shear processor designed to reduce the particle size of solids or the droplet size of liquids within a fluid. It works by forcing the material through a very narrow gap between a high-speed rotating element (the rotor) and a stationary element (the stator). This action creates immense mechanical force, resulting in highly stable and uniform mixtures known as emulsions and dispersions.

The core purpose of a colloidal mill is not to grind hard materials, but to apply intense hydraulic shear. This shear force de-agglomerates clumps of solids or breaks down liquid droplets to a microscopic level, creating a stable, homogeneous final product that resists separation.

How a Colloidal Mill Achieves High Shear

A colloidal mill's effectiveness comes from its core mechanism: the rotor-stator assembly. This simple concept generates complex and powerful forces.

The Rotor-Stator Mechanism

The heart of the mill is a rotor that spins at several thousand RPM. This rotor is positioned with extreme precision inside the stator, with a gap between them that can be as small as a fraction of a millimeter.

Creating Intense Hydraulic Shear

As the product is fed into the mill, it is subjected to intense acceleration as it enters the rotor-stator assembly. It is then forced through the tiny gap at very high velocity. The extreme difference in speed between the fast-moving rotor surface and the non-moving stator surface rips particles and droplets apart.

The Role of Turbulence and Cavitation

The high-speed action also generates significant turbulence. This chaotic flow ensures that all of the material is subjected to the shearing forces. In many cases, it also causes cavitation—the rapid formation and collapse of microscopic bubbles—which creates powerful shockwaves that further assist in breaking down particles.

The End Result: Stable Dispersions and Emulsions

The ultimate goal of this process is to create a product that remains consistent over time. A colloidal mill achieves this in two primary ways.

Creating a Dispersion

For products like paints, inks, or pharmaceutical suspensions, the goal is to break down agglomerates—clumps of solid particles—that are held together by weak forces. The mill's shear force overcomes these forces, dispersing the individual particles uniformly throughout the liquid base.

Creating an Emulsion

For products like mayonnaise, lotions, or salad dressings, the goal is to mix two liquids that do not naturally combine, like oil and water. The mill shatters the droplets of one liquid (e.g., oil) into microscopic sizes, allowing them to be suspended evenly within the other liquid (e.g., water), creating a stable emulsion.

Key Design Variations

Colloidal mills are not one-size-fits-all. Their design and orientation are chosen based on the specific application and manufacturing environment.

Vertical vs. Horizontal Orientation

The orientation of the rotor-stator assembly is a key differentiator. Vertical mills, as described in some designs, feature a centrally located shaft with grinding disks. This design can be ideal for top-entry batch mixing in a tank. Horizontal mills are more common for inline, continuous processing where the product flows through a pipeline.

Inline vs. Batch Processing

Inline mills are installed directly into a piping system, processing material as it flows from one stage to the next. This is ideal for large-volume, continuous production. Batch mills are typically mounted on top of or submerged in a mixing vessel to process a single tank of material at a time.

Understanding the Trade-offs and Limitations

While powerful, a colloidal mill is a specialized tool with specific constraints that are critical to understand.

Significant Heat Generation

The intense friction and shear generate a substantial amount of heat. For heat-sensitive products like certain foods or chemicals, this can be a major issue, often requiring the mill to be fitted with a cooling jacket.

Not a Primary Grinder

A colloidal mill excels at breaking apart soft agglomerates and liquid droplets. It is not effective for the primary size reduction of hard, crystalline, or abrasive solids. Using it for this purpose will result in minimal grinding and rapid wear of the rotor and stator.

Particle Size Limitations

A colloidal mill can typically reduce particle or droplet sizes to the range of 1-10 microns. For creating true nano-dispersions (below 1 micron), other technologies like high-pressure homogenizers or media mills are often required.

Potential for Air Entrainment

In open or top-entry batch systems, the high-speed vortexing action can draw air into the product. If air is undesirable in the final product, a sealed inline system is a better choice.

Making the Right Choice for Your Process

Your choice of mixing technology must align directly with your material properties and production goals.

- If your primary focus is creating stable emulsions (like lotions, creams, or sauces): A colloidal mill is an excellent choice for reducing droplet size and ensuring long-term product stability.

- If your primary focus is dispersing soft solids or powders (like pigments in paint or APIs in pharmaceuticals): The high shear of a colloidal mill will effectively break apart agglomerates for a smooth, uniform texture.

- If your primary focus is grinding hard, crystalline materials (like minerals or ceramics): A colloidal mill is the wrong tool; you should investigate a ball mill, media mill, or jet mill instead.

Understanding the principle of high-shear mixing is the key to leveraging the colloidal mill for superior product quality and consistency.

Summary Table:

| Feature | Description |

|---|---|

| Primary Function | High-shear particle/droplet size reduction via rotor-stator mechanism. |

| Key Applications | Creating stable emulsions (lotions, sauces) and dispersions (paints, inks). |

| Typical Particle Size | 1 to 10 microns. |

| Common Designs | Vertical (batch) and Horizontal (inline) orientations. |

| Key Limitation | Generates significant heat; not for grinding hard, abrasive materials. |

Ready to achieve superior product consistency and stability? KINTEK specializes in precision lab equipment, including colloidal mills, to meet your specific mixing and dispersion needs. Whether you're developing a new lotion, paint, or pharmaceutical suspension, our expertise ensures you get the right high-shear solution for your laboratory. Contact our experts today to discuss how we can enhance your process!

Visual Guide

Related Products

- Laboratory Micro Tissue Grinding Mill Grinder

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- What does a colloid mill do? Achieve Superior Emulsions and Fine Dispersions

- What is the primary role of a light ball mill? Optimize SiC/Cu-Al2O3 Composite Powder Homogeneity

- What laboratory apparatus is used for grinding? Match the Right Mill to Your Sample Material

- Why are laboratory mixers with multi-stage speed regulation required in SSF? Optimize Pulp Liquefaction & Cell Viability

- What is a screw mixer? Achieve Gentle, Homogeneous Blending of Powders

- What is the factor affecting size reduction? Master Material Properties for Optimal Milling

- What is pulverized material? Unlock Material Potential with Precision Grinding

- What is the purpose of colloid milling? Achieve Superior Homogenization and Stability for Your Products