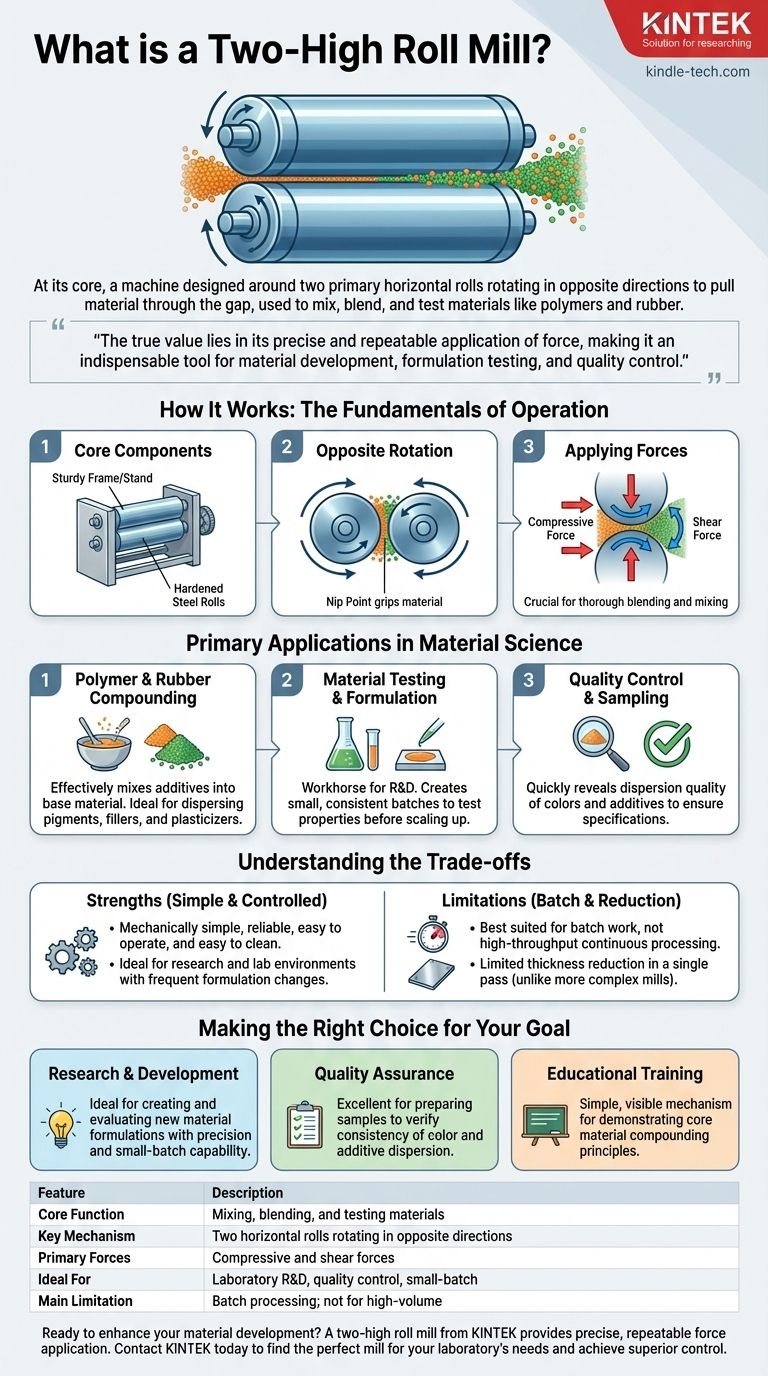

At its core, a two-high roll mill is a machine designed around two primary horizontal rolls positioned one directly above the other. These rolls rotate at the same speed but in opposite directions, pulling material through the gap between them. This simple yet effective mechanism is used to mix, blend, and test various materials, particularly polymers and rubber.

The true value of a two-high roll mill lies not in high-volume production, but in its precise and repeatable application of force, making it an indispensable tool for material development, formulation testing, and quality control.

How It Works: The Fundamentals of Operation

The operational principle of a two-high roll mill is straightforward, relying on the interplay between a few key components and forces.

The Core Components

A two-high mill consists of a sturdy frame or stand that houses two hardened steel rolls. At least one of these rolls is adjustable, allowing the operator to precisely control the distance between them.

The Principle of Opposite Rotation

The two rolls turn towards each other. This counter-rotation creates a "nip point" that grips the material and pulls it into the gap between the rolls.

Applying Compressive and Shear Forces

As material passes through the narrow, adjustable gap, it is subjected to intense compressive force. Simultaneously, the turning of the rolls imparts a shear force throughout the material, which is critical for blending and mixing components together thoroughly.

Primary Applications in Material Science

While the design is simple, its applications are focused and critical in specific industries. The ability to control the process makes it ideal for tasks where precision is paramount.

Polymer and Rubber Compounding

The mill is exceptionally effective at mixing additives into a base material. The shear forces generated are perfect for dispersing pigments for color sampling, blending fillers for strength, or mixing in plasticizers for flexibility in PVC and rubber formulations.

Material Testing and Formulation

In a laboratory setting, the two-high mill is a workhorse. It allows engineers and chemists to create small, consistent batches of new plastic or rubber compounds to test their physical properties before scaling up to larger production.

Quality Control and Sampling

For quality assurance, a small sample of a production batch can be run through the mill. This quickly reveals how well colors and other additives have been dispersed, ensuring the final product meets its specifications.

Understanding the Trade-offs

Like any piece of equipment, the two-high mill's design comes with inherent strengths and limitations that define its ideal use cases.

Strength: Simplicity and Control

The design is mechanically simple, making it reliable, easy to operate, and straightforward to clean between batches. This is a significant advantage in research and lab environments where many different formulations may be tested in a single day.

Limitation: Primarily for Batch Processing

The nature of feeding material into the rolls makes the two-high mill best suited for batch work. It is not designed for the high-throughput, continuous processing seen in large-scale manufacturing lines.

Limitation: Basic Reduction Capability

When used for rolling metals (an early application of the design), the simple two-roll structure is limited in how much it can reduce the thickness in a single pass. More complex mill designs (like four-high or cluster mills) were developed to overcome this for industrial metal production.

Making the Right Choice for Your Goal

Selecting this equipment depends entirely on the intended outcome of your process.

- If your primary focus is research and development: The mill's precision and small-batch capability make it the ideal choice for creating and evaluating new material formulations.

- If your primary focus is quality assurance: It is an excellent tool for preparing samples to verify the consistency of color and additive dispersion in a larger batch.

- If your primary focus is educational training: Its simple, visible mechanism provides a clear and effective way to demonstrate the core principles of material compounding.

Ultimately, the two-high roll mill is a specialized instrument for achieving meticulous control over material properties on a small scale.

Summary Table:

| Feature | Description |

|---|---|

| Core Function | Mixing, blending, and testing materials (e.g., polymers, rubber) |

| Key Mechanism | Two horizontal rolls rotating in opposite directions |

| Primary Forces | Compressive and shear forces for thorough blending |

| Ideal For | Laboratory R&D, quality control, and small-batch processing |

| Main Limitation | Batch processing; not for high-volume continuous production |

Ready to enhance your material development and quality control processes?

A two-high roll mill from KINTEK provides the precise, repeatable force application essential for effective polymer and rubber compounding, formulation testing, and sample analysis. Whether you're in R&D creating new materials or in QA ensuring batch consistency, our lab equipment is designed for your success.

Contact KINTEK today to find the perfect mill for your laboratory's specific needs and achieve superior control over your material properties.

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is meant by two high rolling mill? A Guide to Core Material Processing

- What is a rubber mixing mill used for? Transforming Raw Rubber into High-Performance Compounds

- What is the difference between Banbury and internal mixer? Understanding Rotor Design for Better Mixing

- What is the use of two roll mill? Essential for Polymer Mixing, R&D, and Quality Control

- What is the disadvantage of a two-roll mill? Limited Thickness Reduction Due to Roll Flattening