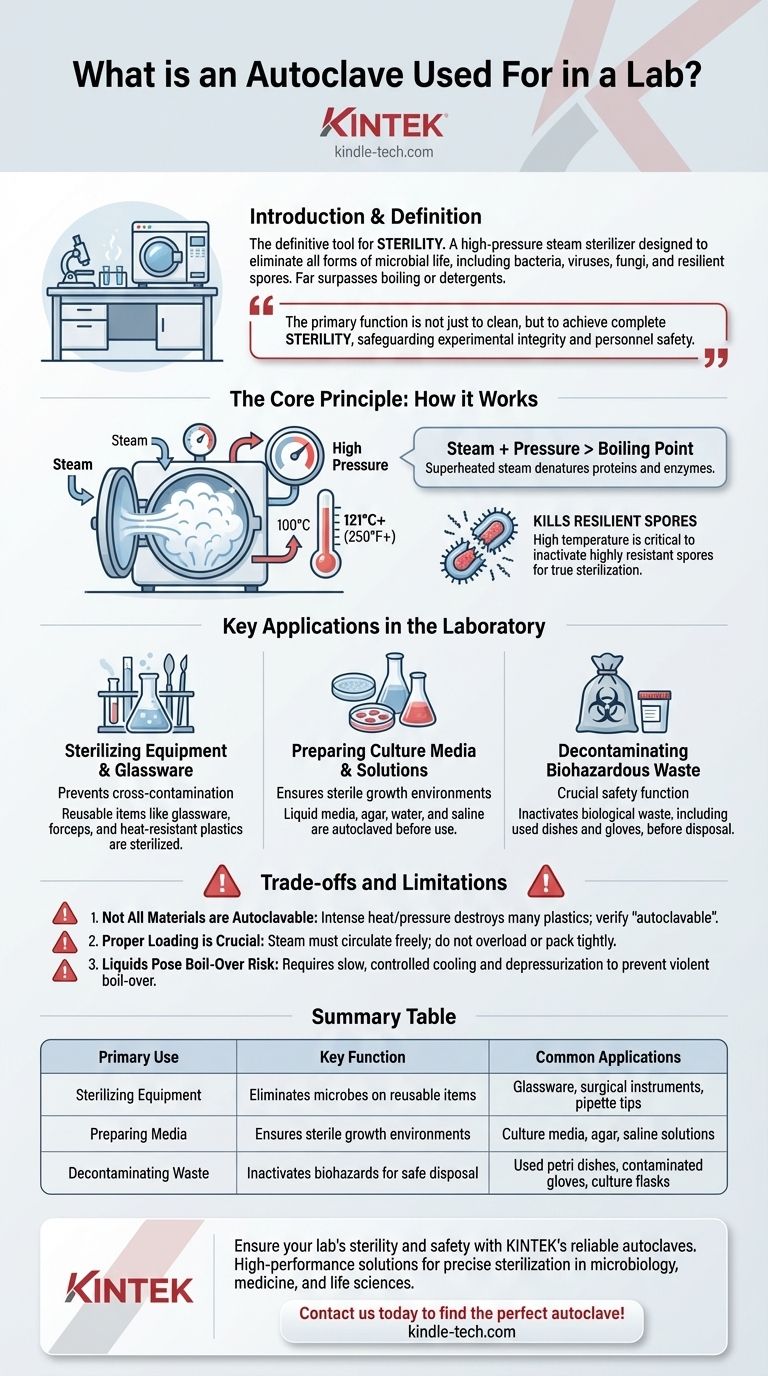

In any laboratory where sterility is non-negotiable, the autoclave serves as the definitive tool for sterilization. It is essentially a high-pressure steam sterilizer designed to eliminate all forms of microbial life, including bacteria, viruses, fungi, and resilient bacterial spores. Its effectiveness far surpasses that of simple boiling or chemical detergents, making it a cornerstone of modern microbiology, medicine, and life science research.

The primary function of an autoclave is not just to clean, but to achieve complete sterility. By using high-pressure steam to reach temperatures above the boiling point of water, it ensures that laboratory instruments, culture media, and hazardous waste are entirely free of living microorganisms, safeguarding both experimental integrity and personnel safety.

The Core Principle: Why Steam is the Gold Standard

At its heart, an autoclave is a sophisticated pressure chamber. Its power lies in a simple principle of physics: increasing pressure raises the boiling point of water. This allows it to create an environment of superheated steam that is lethal to all microbes.

How an Autoclave Works

An autoclave introduces steam into a sealed chamber, increasing the internal pressure. This forces the temperature of the steam well above 100°C (212°F), typically to 121°C (250°F) or higher. This high-temperature, moisture-saturated steam effectively penetrates materials and transfers heat, rapidly denaturing the essential proteins and enzymes that all microorganisms need to survive.

Beyond Boiling: Killing Resilient Spores

Many microorganisms can form highly resistant spores that easily survive boiling water. An autoclave's ability to achieve temperatures of 121°C or more is the critical factor that ensures these spores are inactivated, achieving a true state of sterilization rather than just disinfection.

Key Applications in the Laboratory

Autoclaves are used for two primary purposes: preparing sterile materials for experiments and decontaminating materials after use. This dual function makes them indispensable across a wide range of scientific and medical fields.

Sterilizing Equipment and Glassware

To prevent cross-contamination that would ruin an experiment, all reusable equipment must be sterilized. This includes items like glassware, forceps, surgical instruments, pipette tips, and certain types of heat-resistant plastics and tubes.

Preparing Culture Media and Solutions

In microbiology and tissue culture, the nutrient-rich media used to grow cells must be sterile. If not, unwanted bacteria or fungi will quickly overgrow the desired culture. Autoclaves are used to sterilize liquid media, agar, water, and saline solutions before use.

Decontaminating Biohazardous Waste

Perhaps its most critical safety function is the inactivation of biological waste. All materials that have come into contact with microorganisms—such as used petri dishes, cell culture flasks, and contaminated gloves—must be autoclaved before being discarded. This process kills any potentially pathogenic agents, protecting lab personnel and the environment.

Understanding the Trade-offs and Limitations

While powerful, an autoclave is not a universal solution. Understanding its limitations is crucial for safe and effective operation.

Not All Materials are Autoclavable

The intense heat and pressure will destroy many common materials. Most plastics will melt, sharp instruments can become dull over time, and certain chemicals or reagents can degrade or become hazardous when heated. Always verify that an item is marked as "autoclavable."

Proper Loading is Crucial for Success

Steam must be able to circulate freely to reach every surface. Overloading the autoclave or packing items too tightly can create cold spots where sterilization fails. Lids on containers must be loosened to allow steam to enter and to prevent pressure from building up inside the container itself.

Liquids Pose a Boil-Over Risk

When sterilizing liquids, the cycle must include a slow, controlled cooling and depressurization phase. Releasing pressure too quickly will cause the superheated liquids to boil over violently, creating a severe burn hazard and a mess inside the chamber.

Making the Right Choice for Your Goal

Your specific use of the autoclave will depend on your immediate objective. Follow these guidelines to ensure you are using it correctly for your purpose.

- If your primary focus is experimental integrity: Always autoclave your culture media, solutions, and any equipment that will come into contact with your samples to prevent contamination.

- If your primary focus is laboratory safety: Ensure all biohazardous waste is decontaminated via a validated autoclave cycle before it is removed from the lab for disposal.

- If your primary focus is equipment preparation: Confirm that all instruments and containers are made of autoclave-safe materials and are loaded correctly to allow for complete steam penetration.

Mastering the use of the autoclave is a foundational skill for ensuring both the safety of your laboratory and the success of your scientific work.

Summary Table:

| Primary Use | Key Function | Common Applications |

|---|---|---|

| Sterilizing Equipment | Eliminates microbes on reusable items | Glassware, surgical instruments, pipette tips |

| Preparing Media | Ensures sterile growth environments | Culture media, agar, saline solutions |

| Decontaminating Waste | Inactivates biohazards for safe disposal | Used petri dishes, contaminated gloves, culture flasks |

Ensure your lab's sterility and safety with KINTEK's reliable autoclaves.

KINTEK specializes in high-performance lab equipment, including autoclaves designed for precise sterilization of instruments, media, and hazardous waste. Our solutions help laboratories in microbiology, medicine, and life sciences maintain experimental integrity and protect personnel.

Contact us today to find the perfect autoclave for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the primary purpose of an autoclave in the preparation of media for the biological leaching of uranium?

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity