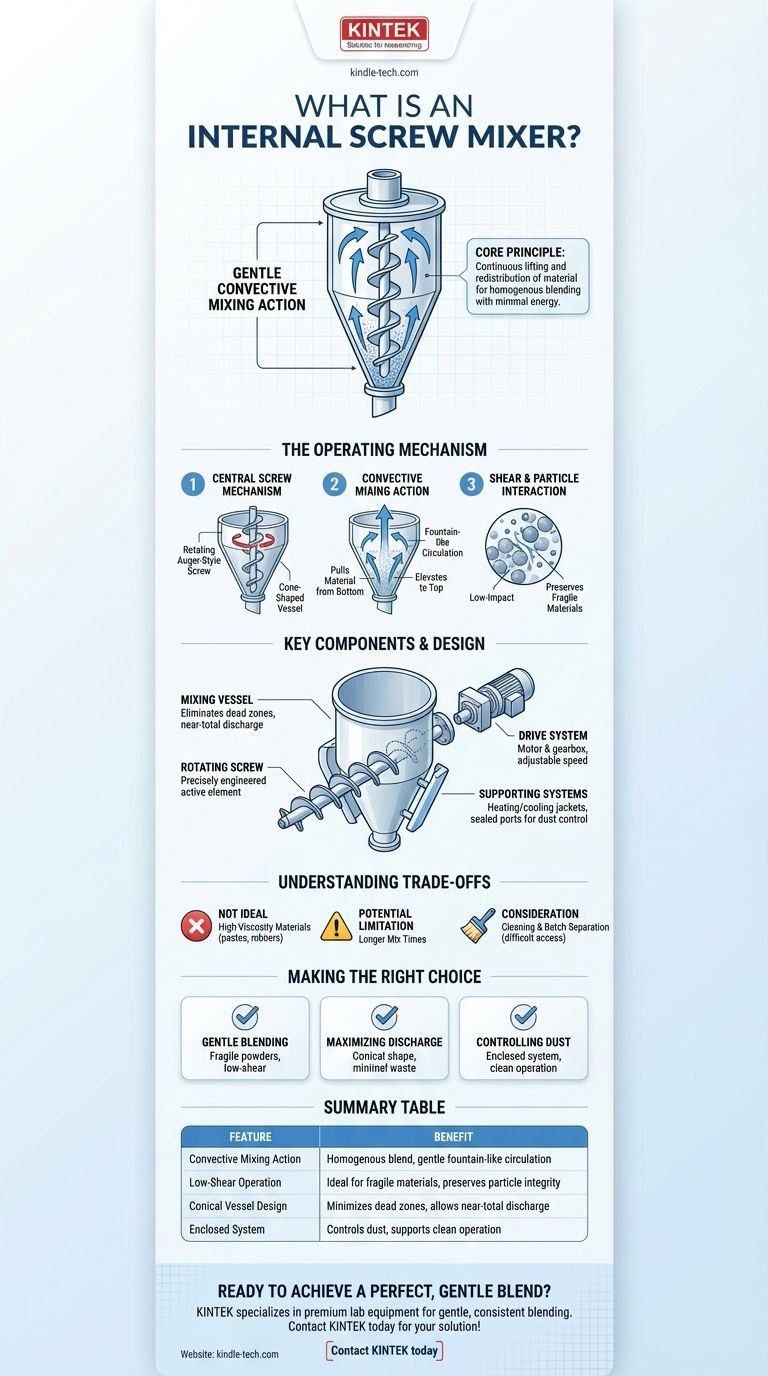

At its core, an internal screw mixer is an industrial machine designed to blend solid materials, such as powders and granules, within a self-contained vessel. It operates using a large, vertically oriented screw that rotates to lift and circulate the material, creating a consistent and homogenous mixture through a gentle, convective action.

The fundamental purpose of an internal screw mixer is to achieve a highly consistent blend of solid particles with minimal energy and product degradation. It accomplishes this by continuously lifting material from the bottom of a container and redistributing it at the top, ensuring all particles are put into motion.

The Core Principle: How an Internal Screw Mixer Operates

An internal screw mixer's effectiveness comes from its simple yet elegant mechanical principle. The entire process is designed to create a thorough mixing pattern without applying excessive force to the ingredients.

The Central Screw Mechanism

The heart of the mixer is a large auger-style screw. This screw is typically housed inside a cone-shaped vessel and rotates on its own axis.

The Convective Mixing Action

As the screw turns, it pulls material from the bottom of the vessel and elevates it to the top. This action creates a continuous fountain-like circulation, forcing the entire batch to move and intermix.

Shear and Particle Interaction

This movement results in the gentle intermingling of solid grains. While some shear force is applied to particles directly in contact with the screw, the overall action is low-impact, making it ideal for fragile materials.

Key Components and Design

The design of these mixers is relatively straightforward, revolving around a few critical components that work in unison to achieve a uniform blend.

The Mixing Vessel

The container is most often a vertical, cone-shaped vessel. This conical shape helps channel all the material down toward the intake of the screw, ensuring there are no "dead zones" where material can sit unmixed.

The Rotating Screw

This is the active mixing element. It is precisely engineered to efficiently lift the specific type of material being processed.

The Drive System

A motor and gearbox provide the power for the screw's rotation. The speed can often be adjusted to control the intensity and speed of the mixing process.

Supporting Systems

Many industrial mixers include additional systems. These can include jackets around the vessel for heating or cooling, sealed charging and discharging ports to control dust, and lubrication systems for the transmission.

Understanding the Trade-offs and Limitations

While highly effective for their intended purpose, internal screw mixers are not a universal solution. Understanding their limitations is key to using them correctly.

Not Ideal for High-Viscosity Materials

These mixers are designed for free-flowing solids. They lack the high-shear force needed to plasticize or mix extremely thick pastes, rubbers, or dense plastics. For those applications, a rotor-based internal mixer (like a Banbury mixer) is required.

Potential for Longer Mix Times

For some material combinations, the gentle action of a screw mixer may require a longer mixing time to achieve complete homogeneity compared to more aggressive, high-shear mixers.

Cleaning and Batch Separation

The large internal screw can be difficult to access and clean thoroughly. This can be a significant consideration in applications where preventing cross-contamination between different batches is critical.

Making the Right Choice for Your Goal

Selecting the correct mixer depends entirely on the materials you are processing and your desired outcome.

- If your primary focus is gently blending fragile powders, granules, or pellets: An internal screw mixer is an excellent choice for its efficient, low-shear mixing action that preserves particle integrity.

- If your primary focus is maximizing product discharge: The conical shape of many screw mixers allows for a near-total discharge of the product, minimizing waste between batches.

- If your primary focus is controlling dust and ensuring clean operation: The fully enclosed design of an internal mixer significantly reduces airborne particles compared to open mixing systems.

Understanding the specific mixing action of an internal screw mixer is the key to matching the right technology to your material processing goals.

Summary Table:

| Feature | Benefit |

|---|---|

| Convective Mixing Action | Creates a homogenous blend through gentle, fountain-like circulation. |

| Low-Shear Operation | Ideal for fragile materials, preserving particle integrity. |

| Conical Vessel Design | Minimizes dead zones and allows for near-total product discharge. |

| Enclosed System | Controls dust and supports clean operation. |

Ready to Achieve a Perfect, Gentle Blend?

If your goal is to efficiently mix fragile powders, granules, or pellets without damaging your product, the right equipment is crucial. KINTEK specializes in premium lab equipment, including mixers designed for gentle, consistent blending.

Our experts can help you select the ideal mixer for your specific materials and throughput requirements, ensuring optimal performance and efficiency in your laboratory.

Contact KINTEK today to discuss your mixing challenges and find your perfect solution!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

- Small Lab Rubber Calendering Machine

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What does calendering do for fabric? Transform Fabric's Look, Feel, and Performance

- What are the three types of rolling mills? A Guide to Boosting Your Metal Production Efficiency

- What are the advantages of a two roll mill? Achieve Superior Polymer Mixing & Quality Control

- What is an internal mixer? A Guide to High-Volume Rubber & Plastic Compounding

- What is the difference between single screw and twin screw? Choose the Right Extruder for Your Process

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films

- What is vulcanizing used for? Unlock the Strength and Durability of Rubber

- What are the disadvantages of screw extrusion? High Costs and Complexity Explained