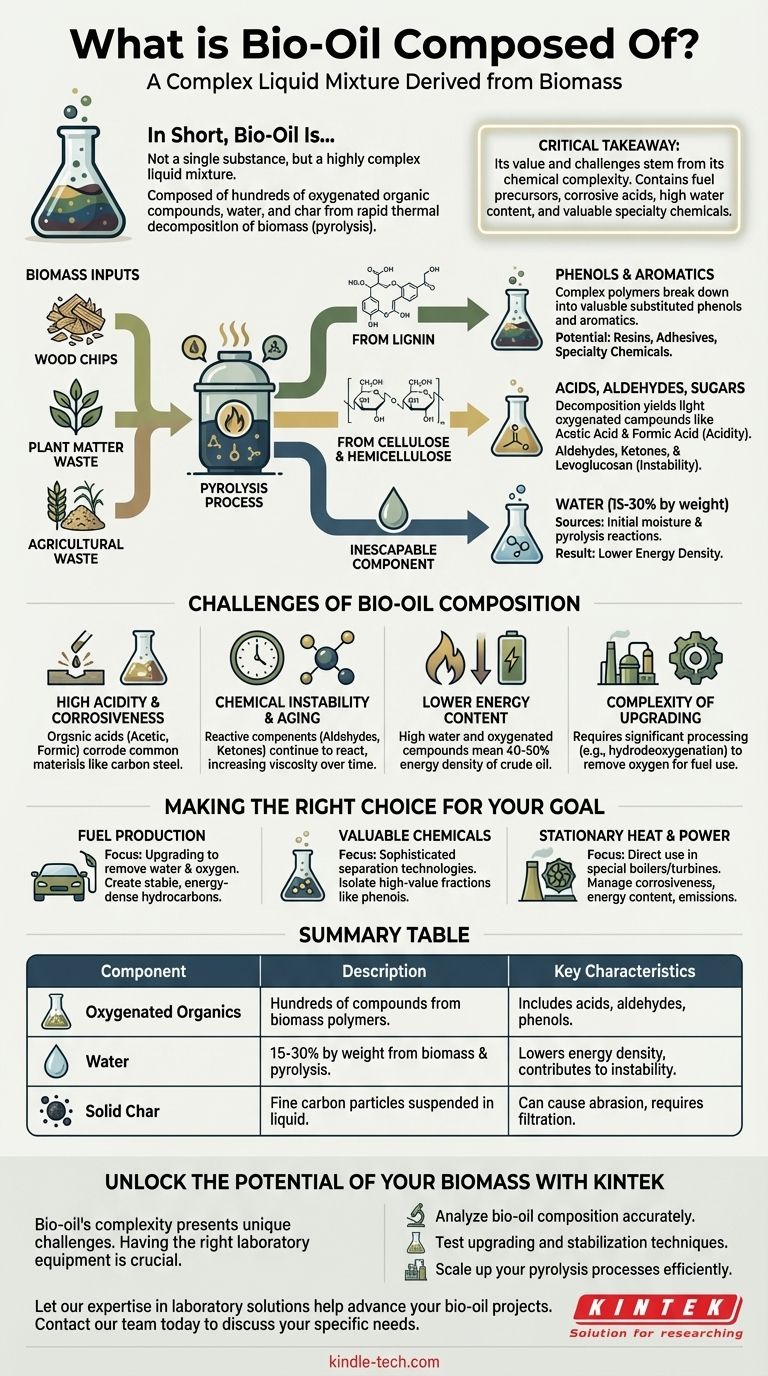

In short, bio-oil is not a single substance but a highly complex liquid mixture. It is composed of hundreds of different oxygenated organic compounds, water, and small amounts of char, all derived from the rapid thermal decomposition of biomass in a process called pyrolysis. Its exact composition varies significantly based on the biomass source and the process conditions used.

The critical takeaway is that bio-oil's value and challenges stem from the same source: its chemical complexity. It contains not only fuel precursors but also corrosive acids, a high water content, and valuable specialty chemicals, making its direct use difficult but its potential for refinement significant.

The Fundamental Building Blocks of Bio-Oil

Bio-oil, also known as pyrolysis oil, is a dark, viscous, and acidic liquid. Its composition is a direct reflection of the three primary components of the original biomass: cellulose, hemicellulose, and lignin.

From Lignin: Phenols and Aromatics

The lignin portion of biomass is a complex polymer that provides structural rigidity to plants. When it breaks down during pyrolysis, it forms a wide array of phenolic and other aromatic compounds.

These are the valuable substituted phenols and aromatics that can be extracted for use in resins, adhesives, and specialty chemicals. This fraction is what gives bio-oil its potential as more than just a fuel.

From Cellulose & Hemicellulose: Acids, Aldehydes, and Sugars

Cellulose and hemicellulose are polymers of sugar molecules. Their decomposition yields a different set of chemicals.

This includes light oxygenated compounds like acetic acid and formic acid, which are responsible for bio-oil's high acidity. It also produces aldehydes, ketones, and sugar derivatives like levoglucosan, which contribute to its instability.

The Inescapable Component: Water

A significant portion of bio-oil is water, typically ranging from 15% to 30% by weight.

This water comes from two sources: the initial moisture in the biomass and the chemical reactions that occur during pyrolysis. This high water content is a primary reason for bio-oil's lower energy density compared to fossil fuels.

Understanding the Trade-offs: The Challenges of Bio-Oil Composition

The unique chemical makeup of bio-oil presents several significant hurdles that must be overcome for its widespread commercial use.

High Acidity and Corrosiveness

The presence of organic acids, primarily acetic and formic acid, makes raw bio-oil highly corrosive to common construction materials like carbon steel. This necessitates the use of more expensive stainless steel for storage and processing equipment.

Chemical Instability and Aging

Bio-oil is not a stable product. The reactive components within it, such as aldehydes and ketones, can continue to react with each other over time. This process, known as aging, causes the oil's viscosity to increase, potentially leading to the formation of solids and phase separation.

Lower Energy Content

The high concentration of both water and oxygenated organic compounds means bio-oil has a much lower heating value than conventional hydrocarbon fuels. Its energy density is typically around 40-50% that of crude oil, meaning you need nearly twice as much to produce the same amount of energy.

Complexity of Upgrading

To be used as a transportation fuel, bio-oil requires significant processing, or "upgrading." This involves removing oxygen through catalytic processes like hydrodeoxygenation. The sheer variety of chemical compounds makes this a technically challenging and expensive endeavor.

Making the Right Choice for Your Goal

Your approach to bio-oil should be dictated by your end objective, as its composition makes it suitable for different pathways.

- If your primary focus is fuel production: Your main challenge is upgrading the oil by removing water and oxygen to create a stable, energy-dense hydrocarbon fuel compatible with existing infrastructure.

- If your primary focus is producing valuable chemicals: Your strategy will center on developing sophisticated and cost-effective separation technologies to isolate high-value fractions, such as the phenols derived from lignin.

- If your primary focus is stationary heat and power: You can potentially use crude bio-oil in specially designed boilers or turbines, but you must manage its corrosiveness, lower energy content, and emissions.

Understanding bio-oil's complex composition is the first step toward unlocking its true potential as a sustainable resource.

Summary Table:

| Component | Description | Key Characteristics |

|---|---|---|

| Oxygenated Organics | Hundreds of compounds from cellulose, hemicellulose, and lignin. | Includes acids (corrosive), aldehydes (unstable), and phenols (valuable chemicals). |

| Water | 15-30% by weight from biomass moisture and pyrolysis reactions. | Lowers energy density and contributes to instability. |

| Solid Char | Fine carbon particles suspended in the liquid. | Can cause abrasion and requires filtration. |

Unlock the Potential of Your Biomass with KINTEK

Bio-oil's complex composition presents unique challenges and opportunities. Whether your goal is fuel production, chemical extraction, or power generation, having the right laboratory equipment is crucial for analysis, process development, and quality control.

KINTEK specializes in supplying the precise lab equipment and consumables you need to:

- Analyze bio-oil composition accurately.

- Test upgrading and stabilization techniques.

- Scale up your pyrolysis processes efficiently.

Let our expertise in laboratory solutions for sustainable technologies help you advance your bio-oil projects. Contact our team today to discuss your specific needs and discover how we can support your research and development.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

- Copper Foam

- Iridium Dioxide IrO2 for Water Electrolysis

People Also Ask

- What is the difference between pyrolysis and incineration? Material Recovery vs. Energy Recovery

- What is a normal heat treatment? Achieve Uniform & Predictable Metal Properties

- What is industrial application of bio-oil? A Guide to Renewable Heat, Power, and Chemicals

- How does sintering increase density? Master the Process for Superior Material Performance

- What is the thermal stability of graphene? A Guide to Temperature Limits and Material Selection

- Why inert gas is used in sputtering? Ensure Pure, Contamination-Free Thin Film Deposition

- What are the heat treatment processes in the heat treatment of steel? Master the Methods for Superior Material Properties

- Why Use Controlled Drying for Zr-doped CaO? Preserve Porosity and Prevent Agglomeration