At its core, a ceramic fiber module is a pre-fabricated, modular block of high-temperature insulation. It is constructed from compressed ceramic fiber blanket and incorporates a built-in anchoring system, specifically engineered to line the interior of industrial furnaces, kilns, and other thermal processing equipment.

The crucial insight is that a ceramic fiber module is not merely insulation material; it is an engineered lining system. Its primary value is transforming a slow, labor-intensive installation process into a rapid, efficient, and predictable one.

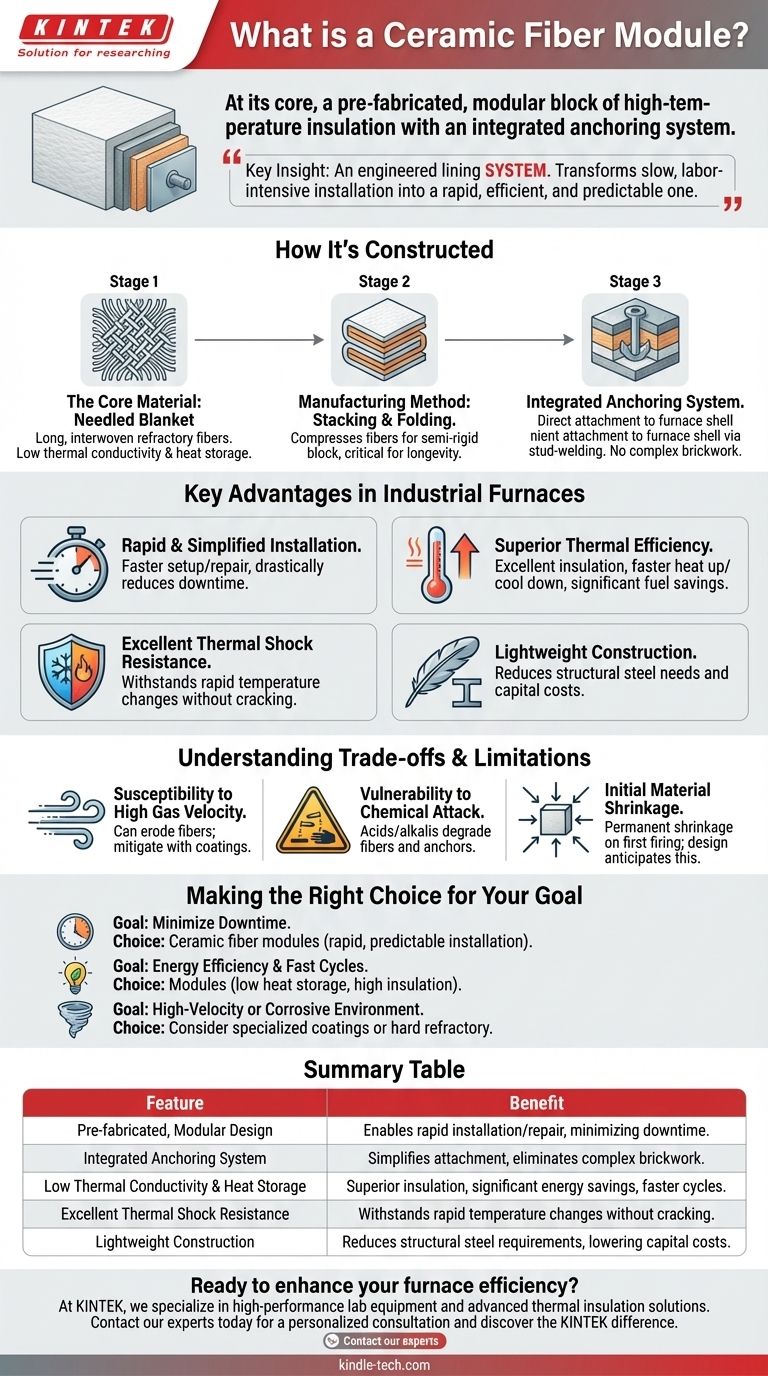

How a Ceramic Fiber Module is Constructed

To understand the module's function, it's essential to understand its components. Each part is designed to work together to provide a robust, thermally efficient furnace lining.

The Core Material: Needled Blanket

The foundation of every module is ceramic fiber blanket. This material is composed of long, interwoven refractory fibers that are needled together to create a strong, lightweight, and highly insulating mat.

This blanket possesses very low thermal conductivity and low heat storage, making it an exceptional insulator for high-temperature applications.

The Manufacturing Method: Stacking and Folding

To create the module's block shape, long strips of this blanket are either stacked on their edges or folded in an accordion-like pattern.

This process compresses the fibers, creating a semi-rigid block that resists being pulled apart. This compression is critical for the module's longevity and performance once installed.

The Integrated Anchoring System

This is what truly defines the component as a module. During manufacturing, a metallic or ceramic anchor system is embedded within the compressed blanket layers.

This integrated anchor allows the module to be directly and quickly attached to the furnace's steel shell, typically with a simple stud-welding process. This eliminates the need for complex brickwork or pouring castable refractory.

The Key Advantages in Industrial Furnaces

The shift from traditional refractories (like brick or castables) to ceramic fiber modules is driven by significant operational and efficiency gains.

Rapid and Simplified Installation

The pre-engineered and modular nature allows for exceptionally fast installation and repair. An entire furnace lining can often be installed in a fraction of the time required for traditional methods, drastically reducing costly downtime.

Superior Thermal Efficiency

Modules provide excellent insulation, which keeps more heat inside the furnace doing productive work. Their low heat storage means the furnace heats up and cools down faster, enabling quicker cycle times and significant fuel savings.

Excellent Thermal Shock Resistance

Because the lining is composed of resilient fibers rather than a solid, rigid material, it can expand and contract without cracking. This makes it highly resistant to the damage caused by rapid temperature changes.

Lightweight Construction

Ceramic fiber is significantly lighter than brick or castable refractories. This reduces the structural steel requirements for the furnace shell, lowering overall capital costs.

Understanding the Trade-offs and Limitations

While highly effective, ceramic fiber modules are not the solution for every application. Objectivity requires acknowledging their operational limits.

Susceptibility to High Gas Velocity

In environments with very high-velocity hot gases, the stream can physically erode the soft fibers over time. This can be mitigated with surface coatings but remains a key consideration.

Vulnerability to Chemical Attack

Certain corrosive atmospheres, particularly those containing acids or alkalis, can degrade the ceramic fibers and the metallic anchor components, leading to premature failure.

Initial Material Shrinkage

Upon first firing to operating temperature, ceramic fiber will undergo a degree of permanent shrinkage. Module design anticipates this, with the compressed folds expanding to fill the gaps, but it is a physical characteristic of the material.

Making the Right Choice for Your Goal

Selecting the correct lining is a matter of matching the material's strengths to your primary operational objective.

- If your primary focus is minimizing downtime for installation or repair: Ceramic fiber modules are the superior choice due to their rapid, predictable installation system.

- If your primary focus is energy efficiency and fast cycle times: The low heat storage and high insulating value of modules offer a distinct advantage over dense refractories.

- If your primary focus is operating in a high-velocity or corrosive environment: You must carefully consider specialized surface coatings for modules or evaluate if a hard refractory lining is more appropriate.

By understanding them as an engineered system, you can effectively leverage ceramic fiber modules to enhance furnace efficiency and reduce operational downtime.

Summary Table:

| Feature | Benefit |

|---|---|

| Pre-fabricated, Modular Design | Enables rapid installation and repair, minimizing downtime. |

| Integrated Anchoring System | Simplifies attachment to the furnace shell, eliminating complex brickwork. |

| Low Thermal Conductivity & Heat Storage | Provides superior insulation, leading to significant energy savings and faster cycle times. |

| Excellent Thermal Shock Resistance | Withstands rapid temperature changes without cracking. |

| Lightweight Construction | Reduces structural steel requirements for the furnace, lowering capital costs. |

Ready to enhance your furnace efficiency and reduce downtime?

At KINTEK, we specialize in providing high-performance lab equipment and consumables, including advanced thermal insulation solutions. Our expertise can help you select the ideal ceramic fiber module system for your specific industrial furnace or kiln application, ensuring maximum energy savings and operational reliability.

Contact our experts today for a personalized consultation and discover the KINTEK difference in thermal processing.

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Custom Boron Nitride (BN) Ceramic Parts

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is ceramic insulation used for? Master High-Temperature Solutions for Industrial Efficiency

- What is the role of zirconia fiber felt in Si2N2O synthesis? Ensuring Thermal Efficiency and Electrical Safety

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- What is the maximum temperature for ceramics? Find the Right Material for Your High-Temp Application

- Why are platinum electrode wires wrapped in oxidized zirconia coils? Ensure Signal Integrity in High-Temp Systems