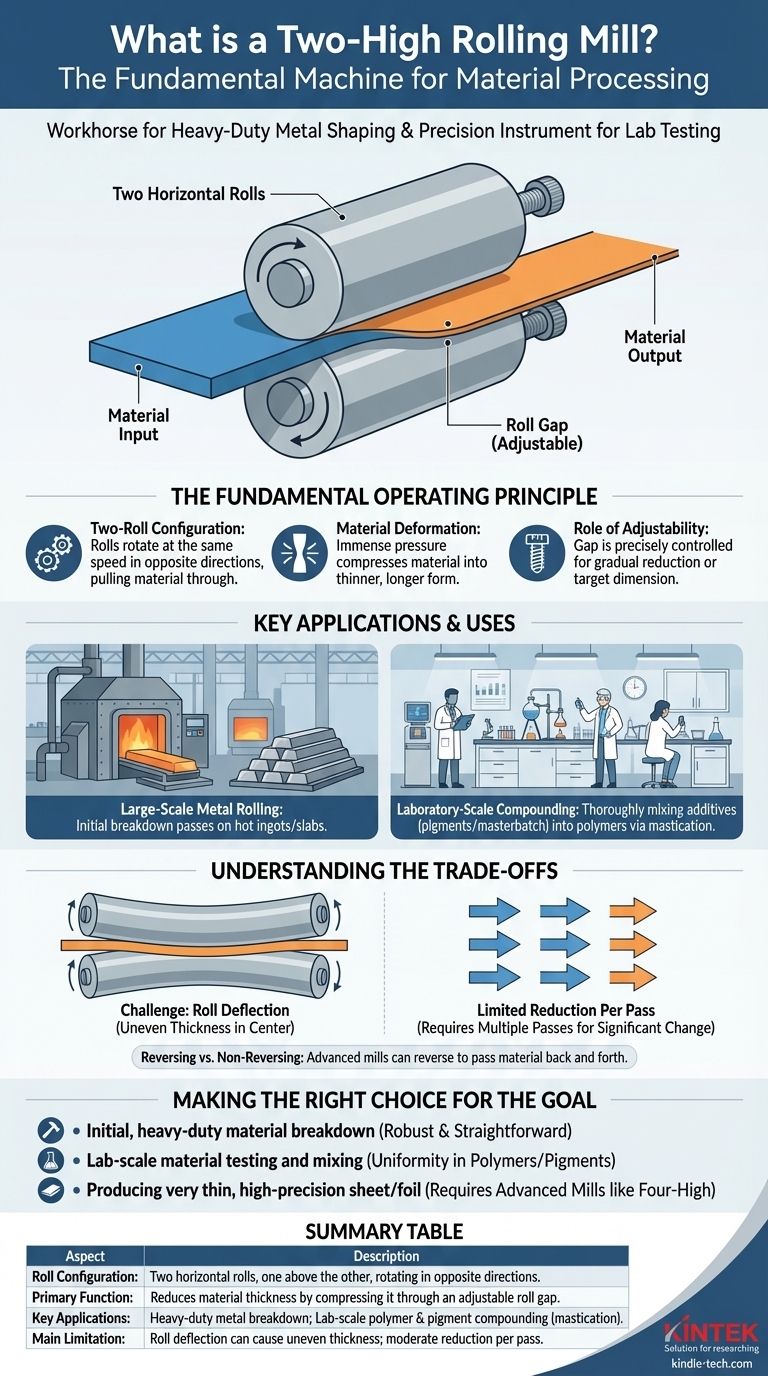

In material processing, a two-high rolling mill is a machine designed with two horizontal rolls positioned one directly above the other. These rolls rotate at the same speed but in opposite directions. The core function is to reduce the thickness of a material, such as metal or polymer, by passing it through the gap between these two rolls.

A two-high mill is the most fundamental design for rolling operations. Its simplicity makes it versatile, serving as a workhorse for heavy-duty metal shaping and as a precise instrument for laboratory-scale material testing and compounding.

The Fundamental Operating Principle

The effectiveness of a two-high mill comes from its straightforward mechanical design. The interaction between the rolls and the material dictates the entire process.

The Two-Roll Configuration

A two-high mill stand consists of two horizontal rolls. The material to be processed is fed into the gap between them. The rolls turn in opposite directions, pulling the material through the gap.

Material Deformation

The distance between the two rolls, known as the roll gap, is set to be smaller than the initial thickness of the material. As the material is drawn through, the immense pressure exerted by the rolls compresses and squeezes it, causing it to become thinner and longer.

The Role of Adjustability

To control the final thickness of the product, one or both of the rolls are adjustable. This allows an operator to precisely change the size of the roll gap for each pass, achieving a gradual reduction in thickness or hitting a specific target dimension.

Key Applications and Uses

The same basic design is employed for vastly different scales and purposes, from massive industrial factories to small research and development labs.

Large-Scale Metal Rolling

In heavy industry, large two-high mills are often used for the initial stages of metal forming. They are ideal for the first "breakdown" passes on hot ingots or slabs, reducing them into more manageable plates or sheets for further processing.

Laboratory-Scale Compounding

On a much smaller scale, a two-roll mill is a critical piece of lab equipment for polymer science and pigment manufacturing. It is used to compound materials—thoroughly mixing additives like pigments or masterbatch into a base polymer.

This process of kneading and mixing, known as mastication, ensures the final material is uniform and that the properties of the additives are evenly distributed.

Understanding the Trade-offs

While effective, the simplicity of the two-high design comes with inherent limitations that are important to understand.

The Challenge of Roll Deflection

The immense forces required for rolling can cause the rolls to bend slightly in the middle. This phenomenon, known as roll deflection, can result in the finished material being slightly thicker in the center than it is at the edges.

Limited Reduction Per Pass

Compared to more complex mill designs, a two-high mill can typically achieve only a moderate reduction in thickness with each pass. For significant size changes, the material may need to be run through the mill multiple times.

Reversing vs. Non-Reversing Mills

The simplest two-high mills are non-reversing, meaning the material can only pass through in one direction. More advanced reversing mills can change the rotational direction of the rolls, allowing the material to be passed back and forth efficiently without needing to be moved from one side of the mill to the other.

Making the Right Choice for the Goal

Understanding the two-high mill's capabilities helps place it within the broader landscape of material processing technology.

- If your primary focus is initial, heavy-duty material breakdown: The two-high mill is a robust and straightforward choice for the first stages of shaping large metal slabs.

- If your primary focus is lab-scale material testing and mixing: A two-roll mill is an essential tool for ensuring the uniformity of polymers, pigments, and other compounds before scaling up to production.

- If your primary focus is producing very thin, high-precision sheet or foil: The limitations of roll deflection mean you would typically use more advanced four-high or cluster mills, which are specifically designed to counteract this effect.

By grasping the function and limitations of this foundational design, you can better understand the principles that drive all rolling technologies.

Summary Table:

| Aspect | Description |

|---|---|

| Roll Configuration | Two horizontal rolls, one above the other, rotating in opposite directions. |

| Primary Function | Reduces material thickness by compressing it through an adjustable roll gap. |

| Key Applications | Heavy-duty metal breakdown; Lab-scale polymer & pigment compounding (mastication). |

| Main Limitation | Roll deflection can cause uneven thickness; moderate reduction per pass. |

Ready to enhance your material processing or compounding? Whether you're breaking down metal slabs in an industrial setting or ensuring polymer uniformity in your R&D lab, KINTEK's expertise in lab equipment is your key to precision and efficiency. Our solutions are designed to meet the exacting demands of laboratory workflows. Contact our experts today to find the perfect rolling mill for your application!

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- What is a rubber milling machine? A Guide to Compounding vs. Grinding

- What is the internal structure of a mixer? A Guide to Core Components and Operation

- What are the disadvantages of twin screw? Higher Cost and Complexity vs. Single Screw

- What are the advantages of twin screw extruder? Superior Mixing, Flexibility & Efficiency

- How profitable is injection molding? Unlock High-Volume Manufacturing Profitability

- What is the difference between extrusion coating and extrusion lamination? A Guide to Material Enhancement

- What is the raw material for blown film extrusion? Selecting the Right Polyethylene for Your Film

- What are the advantages of coextrusion? Achieve Multi-Material Efficiency and Superior Performance