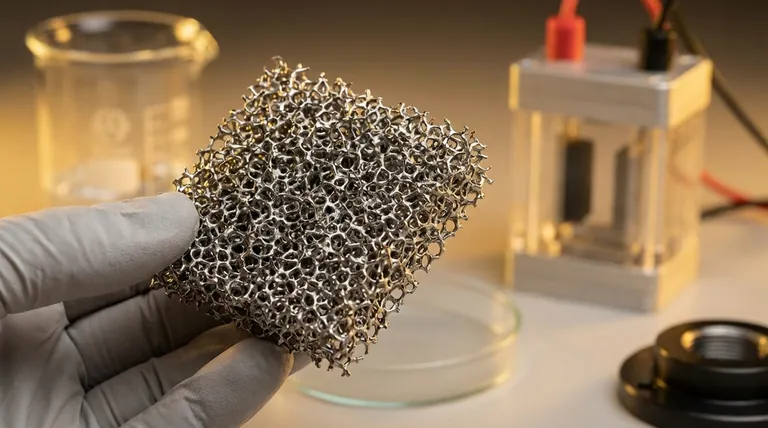

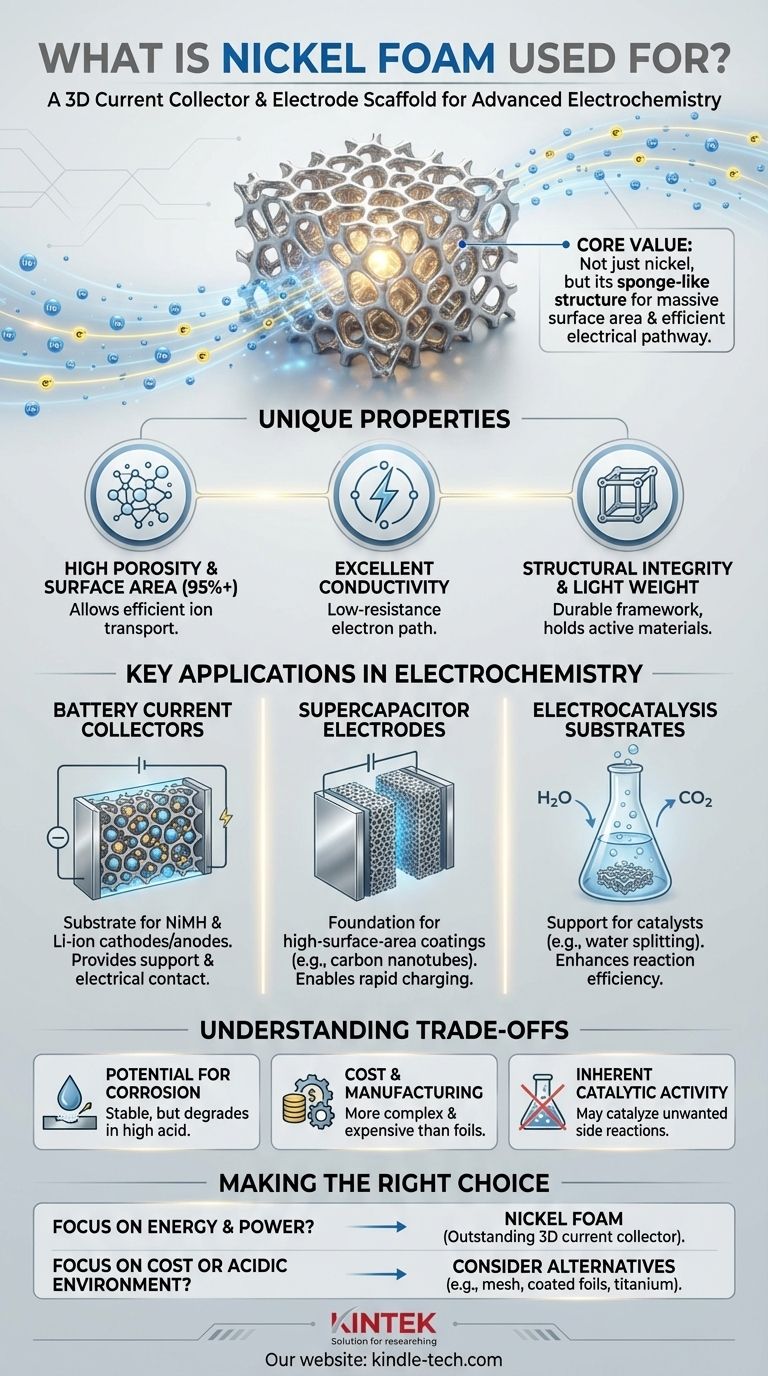

At its core, nickel foam is primarily used as a three-dimensional current collector and electrode substrate in a wide range of electrochemical applications. Its unique combination of high porosity, excellent electrical conductivity, and structural uniformity makes it an ideal scaffold for holding active materials in batteries, supercapacitors, and catalysts.

The true value of nickel foam isn't the nickel itself, but its unique, sponge-like structure. This architecture provides an enormous surface area and an efficient electrical pathway, making it a foundational component for next-generation energy storage and conversion devices.

The Unique Properties of Nickel Foam

To understand why nickel foam is so widely used, you must first appreciate its distinct physical characteristics. It is not simply a block of nickel, but a highly engineered material.

High Porosity and Surface Area

The foam consists of an interconnected, open-cell network, making it over 95% empty space. This structure is critical.

It allows electrolytes in a battery or supercapacitor to flow freely and deeply into the electrode, ensuring efficient ion transport. This vast internal surface area provides abundant sites for electrochemical reactions to occur, dramatically boosting device performance.

Exceptional Conductivity

As a metallic material, nickel is an inherently good electrical conductor. The interconnected ligaments of the foam create a continuous, low-resistance path for electrons to travel.

This makes it an ideal current collector, efficiently channeling the electricity generated during a reaction to the external circuit with minimal energy loss.

Structural Integrity and Light Weight

Despite being mostly void space, the foam's metallic skeleton is self-supporting and mechanically robust. It acts as a durable framework that holds the active materials, preventing them from cracking or detaching during operation.

Its light weight is a significant advantage in applications like electric vehicles and portable electronics, where minimizing mass is crucial.

Key Applications in Electrochemistry

The properties of nickel foam make it a versatile platform for several high-performance applications.

Current Collectors in Batteries

In rechargeable batteries, particularly Nickel-Metal Hydride (NiMH) and some lithium-ion chemistries, nickel foam serves as the substrate for the cathode or anode.

Active materials (the substances that store energy) are pasted into the pores of the foam. The foam provides mechanical support and ensures excellent electrical contact throughout the entire electrode volume.

Electrodes for Supercapacitors

Supercapacitors store energy by accumulating ions on the surface of an electrode. Nickel foam's massive surface area makes it a perfect foundation for these devices.

By growing or coating materials with even higher surface areas, like carbon nanotubes or metal oxides, onto the foam, engineers can create electrodes that enable extremely rapid charging and discharging.

Substrates for Electrocatalysis

In processes like water splitting (producing hydrogen and oxygen), nickel foam serves as a high-surface-area support for catalytic materials.

The foam's conductivity and open structure enhance the efficiency of the catalyst, which speeds up the chemical reaction. In some alkaline environments, the nickel foam itself can act as a cost-effective catalyst.

Understanding the Trade-offs

While highly effective, nickel foam is not a universal solution. Understanding its limitations is key to proper application.

Potential for Corrosion

Nickel is stable in many environments but can corrode or dissolve in highly acidic solutions. This can degrade the electrode structure and contaminate the electrochemical system over time.

Cost and Manufacturing

Producing high-quality, uniform nickel foam is a more complex and expensive process than creating simple nickel foils or meshes. For cost-sensitive applications, it may not be the most economical choice.

Inherent Catalytic Activity

While sometimes beneficial, nickel's own catalytic properties can be a drawback. In certain reactions, it might catalyze unwanted side reactions, reducing the overall efficiency and selectivity of the intended process.

Making the Right Choice for Your Goal

Selecting the right electrode material depends entirely on your specific performance targets, operating environment, and budget.

- If your primary focus is maximizing energy density and power: Nickel foam is an outstanding choice as a 3D current collector for thick electrodes in high-performance batteries and supercapacitors.

- If your primary focus is cost-sensitivity for a large-scale application: A simpler substrate like expanded nickel mesh or carbon-coated aluminum foil might be a more practical alternative.

- If your primary focus is operation in a highly acidic or corrosive environment: You should consider more inert materials like titanium foam, or use a nickel foam with a protective coating (e.g., gold or carbon).

By serving as a conductive, high-surface-area scaffold, nickel foam empowers the active materials that define the future of energy technology.

Summary Table:

| Property | Key Benefit | Primary Application |

|---|---|---|

| High Porosity (95%+) | Massive surface area for reactions | Supercapacitors, Catalysis |

| Excellent Conductivity | Efficient electron transport | Battery Current Collectors |

| Structural Integrity | Durable, lightweight framework | Electrodes for Energy Storage |

| 3D Scaffold | Holds active materials securely | Next-generation Batteries |

Optimize your electrochemical projects with KINTEK's high-performance nickel foam. As a leading supplier of lab equipment and consumables, we provide the reliable materials you need to enhance your battery, supercapacitor, and catalysis research. Our nickel foam ensures superior conductivity and structural support for your most demanding applications. Contact our experts today to discuss how KINTEK can support your laboratory's innovation and efficiency goals.

Visual Guide

Related Products

- Copper Foam

- High Purity Zinc Foil for Battery Lab Applications

- Aluminum Foil Current Collector for Lithium Battery

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

People Also Ask

- What electrostatic protection measures should be taken when using nickel and copper foam? Essential ESD Safety Protocols

- Is metal foam expensive? Unpacking the High Cost of Advanced Materials

- What are the proper storage conditions for nickel and copper foam? A Guide to Preserving Performance

- What are the downsides of using metal foam? Understanding the Trade-offs of a Specialist Material

- How do you transfer graphene from copper? A Step-by-Step Guide to Preserving Pristine Quality

- What does copper memory foam do? Sleep Cooler and Healthier with Advanced Thermal Regulation

- How do you make copper foam? A Step-by-Step Guide to Creating Porous Metal Structures

- What are the common applications of copper foam? A Guide to Its High-Performance Uses