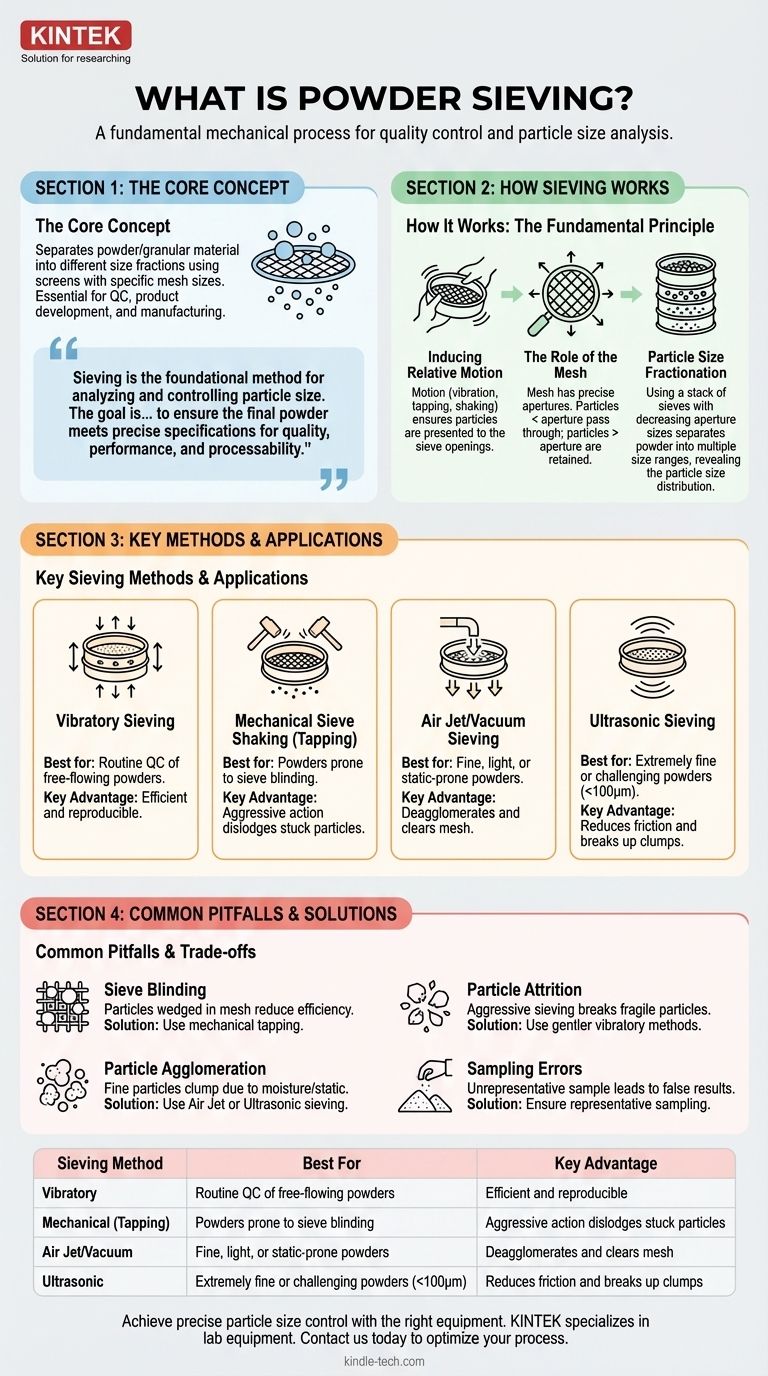

At its core, powder sieving is a mechanical process used to separate a powder or granular material into different particle size fractions. It works by passing the material through a screen, or a series of screens, with a specific mesh size. This fundamental technique is not just about sorting; it is a critical step in quality control, product development, and manufacturing across countless industries.

Sieving is the foundational method for analyzing and controlling particle size. The goal is not merely to separate particles, but to ensure the final powder meets precise specifications for quality, performance, and processability.

The Fundamental Principle: How Sieving Works

The entire process is governed by a simple mechanical interaction: creating relative motion between the particles and a sieve mesh. This allows gravity and momentum to perform the separation.

Inducing Relative Motion

To begin, a sample of the powder is placed onto a sieve or a stack of sieves. The equipment then applies motion—typically vibration, tapping, or shaking. This agitation ensures that all particles are presented to the sieve openings multiple times and from different angles.

The Role of the Mesh

Each sieve contains a wire mesh with precisely measured openings, known as apertures. As the sieve moves, particles smaller than the aperture size fall through to the sieve below or a collection pan. Particles larger than the aperture size are retained on the mesh surface.

The Result: Particle Size Fractionation

When a stack of sieves with progressively smaller apertures is used, the powder sample is effectively separated into multiple size ranges, or fractions. The material retained on each sieve gives a clear picture of the product's particle size distribution, a critical quality metric.

Key Sieving Methods and Their Applications

While the principle is universal, different methods are used to handle various material types and analysis goals.

Vibratory Sieving

This is the most common method. The sieve stack is subjected to electromagnetic vibration, which creates a vertical tossing motion combined with a slight rotation. This is highly efficient and reproducible for a wide range of free-flowing powders from 20 microns up to several millimeters.

Mechanical Sieve Shaking (Tapping)

In addition to a horizontal shaking motion, this method incorporates a vertical "tapping" or "hammering" action. This aggressive motion is particularly effective at preventing sieve blinding by dislodging near-size particles that can get stuck in the mesh openings.

Air Jet or Vacuum Sieving

This technique is ideal for very fine, light, or electrostatically charged powders that tend to agglomerate. A vacuum pulls air downwards through a single sieve, while a rotating nozzle below blows air upwards. This fluidizes the powder bed, deagglomerates particles, and continuously clears the mesh.

Ultrasonic Sieving

For extremely fine or challenging powders (below 100 microns), high-frequency ultrasonic waves can be applied directly to the sieve mesh. This secondary vibration reduces friction, breaks up static clumps, and dramatically improves the passage of very fine particles.

Understanding the Trade-offs and Common Pitfalls

Achieving an accurate and repeatable sieve analysis requires awareness of potential problems.

Sieve Blinding

This is the most frequent issue, where particles with a size very close to the sieve's aperture become wedged in the mesh. Blinding reduces the available open area of the sieve, leading to inefficient separation and inaccurate results.

Particle Agglomeration

Fine particles can clump together due to moisture or electrostatic forces. These clumps behave like larger particles and may fail to pass through a mesh they would otherwise fit through, skewing the distribution toward coarser sizes.

Particle Attrition

Excessively long or aggressive sieving, especially with mechanical tappers, can damage or break down friable (brittle) particles. This creates more fine particles than were present in the original sample, leading to a false-fine result.

Sampling Errors

The analysis is only as good as the initial sample. If the sample taken for sieving is not representative of the entire batch of powder, the results will not reflect the true particle size distribution of the product.

Making the Right Choice for Your Goal

Your choice of sieving method and parameters depends directly on your material and your objective.

- If your primary focus is routine quality control for standard powders: Standard vibratory sieving is the most reliable, cost-effective, and widely accepted method.

- If your primary focus is analyzing very fine, cohesive, or static-prone powders: Air jet or ultrasonic sieving will be necessary to overcome agglomeration and ensure accurate results.

- If your primary focus is preventing sieve blinding with near-size particles: A mechanical sieve shaker with a tapping motion is often the most effective solution.

Ultimately, mastering sieving gives you direct control over one of the most critical variables defining your material's behavior and final product quality.

Summary Table:

| Sieving Method | Best For | Key Advantage |

|---|---|---|

| Vibratory | Routine QC of free-flowing powders | Efficient and reproducible |

| Mechanical (Tapping) | Powders prone to sieve blinding | Aggressive action dislodges stuck particles |

| Air Jet/Vacuum | Fine, light, or static-prone powders | Deagglomerates and clears mesh |

| Ultrasonic | Extremely fine or challenging powders (<100μm) | Reduces friction and breaks up clumps |

Achieve precise particle size control with the right equipment. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the ideal sieving solution for your specific powder, whether for quality control, R&D, or production. Contact us today to optimize your process and ensure your product meets its exact specifications.

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

People Also Ask

- What is a sieve used for in a lab? Ensure Material Consistency with Precise Particle Size Analysis

- What are the steps in a sieving test? Master the Systematic Procedure for Accurate Particle Analysis

- What are the limitations of sieving? Understanding the Constraints of Particle Size Analysis

- What are the different methods of sieving? Choose the Right Technique for Your Material

- What is the process of sieving? A Step-by-Step Guide to Accurate Particle Size Analysis

- Why is the use of standard sieving systems necessary for corn stover? Maximize Lignin Degradation with KINTEK

- What are the possible sources of error in sieve analysis test? Avoid Costly Mistakes and Ensure Data Accuracy

- What is the importance of particle size analysis by sieving? Ensure Product Quality and Performance