The lifespan of a dental restoration is not a fixed number, but a range influenced by material, location, and patient care. While a silver amalgam filling may last 15 years or more and a gold crown can last for decades, a tooth-colored composite filling typically has a lifespan of 5 to 10 years. These are only averages, and the true longevity of any dental work depends heavily on other critical factors.

The most durable materials like gold or zirconia provide the longest potential lifespan, but your personal oral hygiene, diet, and habits like teeth grinding are the single most significant factors in determining how long any restoration actually lasts. The "best" material is meaningless without proper patient care.

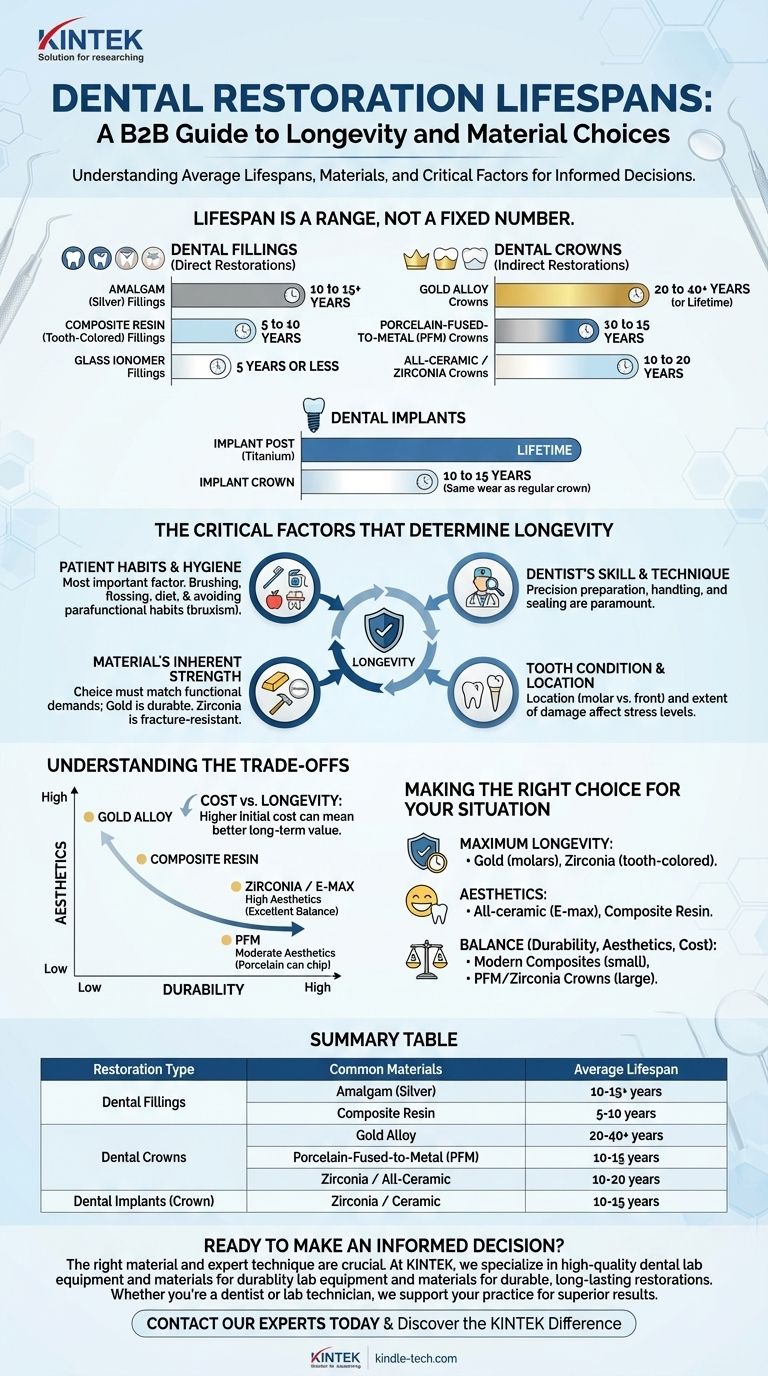

Average Lifespan by Restoration Type

A "restoration" is any material used to repair or replace tooth structure. The expected lifespan varies significantly based on the type of restoration and the material used.

Dental Fillings (Direct Restorations)

Fillings are placed directly into a prepared tooth cavity in a single visit.

- Amalgam (Silver) Fillings: These are known for their durability and have a long track record. They can easily last 10 to 15 years, and it's not uncommon for them to last much longer.

- Composite Resin (Tooth-Colored) Fillings: While early versions were less durable, modern composites are significantly stronger. Their average lifespan is 5 to 10 years, though with excellent care in low-stress areas, they can last longer.

- Glass Ionomer Fillings: These materials are weaker than composite and are typically used in non-biting surfaces, on baby teeth, or as a temporary base. Their lifespan is generally 5 years or less.

Dental Crowns (Indirect Restorations)

Crowns are fabricated outside the mouth and cemented onto the tooth. They cover the entire tooth and provide superior strength for heavily damaged teeth.

- Gold Alloy Crowns: These are the gold standard for longevity. Their soft nature means they wear at a rate similar to natural teeth and are unlikely to chip or break. Gold crowns can last 20 to 40 years or even a lifetime.

- Porcelain-Fused-to-Metal (PFM) Crowns: A metal substructure provides strength while a porcelain overlay provides aesthetics. They are very strong but the porcelain can chip over time. Their typical lifespan is 10 to 15 years.

- All-Ceramic or All-Porcelain Crowns (Zirconia, E-max): Modern ceramics offer an excellent blend of strength and aesthetics. Zirconia, in particular, is exceptionally strong and fracture-resistant. You can expect these to last 10 to 20 years.

A Note on Dental Implants

A dental implant is a titanium post that replaces the root of a missing tooth. The implant itself can integrate with the bone and last a lifetime. The crown that attaches to the implant, however, is subject to the same wear and tear as a regular crown and will likely need replacement every 10 to 15 years.

The Critical Factors That Determine Longevity

The material's average lifespan is just a starting point. The following factors will ultimately determine the success and longevity of your dental work.

Your Role: Patient Habits and Hygiene

This is the most important factor and the one you control. Excellent brushing and flossing prevent new decay from forming around the edges of a restoration, which is a primary cause of failure.

A high-sugar or acidic diet increases the risk of decay. Furthermore, parafunctional habits like teeth grinding (bruxism), clenching, or chewing on ice can dramatically shorten the life of any restoration by subjecting it to extreme forces.

The Dentist's Skill and Technique

The precision with which a dentist prepares the tooth, handles the material, and ensures a perfect seal is paramount. A well-executed restoration by a skilled clinician will always outperform a poorly executed one, regardless of the material used.

The Material's Inherent Strength

As outlined above, some materials are simply stronger than others. Gold's malleability makes it incredibly durable, while Zirconia's hardness makes it fracture-resistant. The choice of material must be matched to the functional demands of the tooth.

The Condition and Location of the Tooth

A restoration on a molar, which endures immense chewing forces, is under more stress than one on a front tooth. Likewise, a small filling on an otherwise healthy tooth is likely to last longer than a large crown on a tooth that was already severely compromised.

Understanding the Trade-offs

Choosing a restoration is a balance of competing priorities. There is no single "best" material for every situation.

Durability vs. Aesthetics

This is the classic trade-off. Gold is the longest-lasting material but is not tooth-colored. Modern ceramics like Zirconia offer an excellent compromise, providing both high strength and great aesthetics, but they still may not match the longevity of gold.

Cost vs. Longevity

More durable and complex restorations like gold or ceramic crowns have a higher upfront cost than a simple composite filling. However, their extended lifespan can make them more cost-effective over the long term by avoiding the need for repeated replacements.

Conservation of Tooth Structure

Fillings, inlays, and onlays are more conservative options that preserve more of your natural tooth. A crown requires significantly more tooth reduction but offers greater structural support for a weakened tooth. The right choice depends on the extent of the damage.

Making the Right Choice for Your Situation

Discuss your personal goals and habits with your dentist to select the ideal restoration for your specific needs.

- If your primary focus is maximum longevity: A gold restoration is the undisputed champion, especially for out-of-sight molars. Zirconia is the strongest tooth-colored alternative.

- If your primary focus is aesthetics: All-ceramic restorations (like E-max) and composite resin fillings are the best choice for teeth visible when you smile.

- If your primary focus is a balance of durability, aesthetics, and cost: Modern composite fillings for smaller cavities and PFM or Zirconia crowns for larger restorations offer an excellent middle ground.

Ultimately, the best dental restoration is one that is chosen wisely and cared for diligently.

Summary Table:

| Restoration Type | Common Materials | Average Lifespan |

|---|---|---|

| Dental Fillings | Amalgam (Silver) | 10-15+ years |

| Dental Fillings | Composite Resin | 5-10 years |

| Dental Crowns | Gold Alloy | 20-40+ years |

| Dental Crowns | Porcelain-Fused-to-Metal (PFM) | 10-15 years |

| Dental Crowns | Zirconia / All-Ceramic | 10-20 years |

| Dental Implants (Crown) | Zirconia / Ceramic | 10-15 years |

Ready to make an informed decision about your dental restoration?

The right material and expert technique are crucial for maximizing the lifespan of your dental work. At KINTEK, we specialize in providing high-quality dental lab equipment and materials that help dental professionals create durable, long-lasting restorations. Whether you're a dentist seeking reliable materials or a lab technician looking for precision equipment, we have the solutions to support your practice and ensure patient satisfaction.

Let's discuss how we can help you achieve superior results. Contact our experts today for personalized recommendations and discover the KINTEK difference in dental laboratory excellence.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the uses of ceramics in dentistry? Achieve Lifelike, Durable Restorations

- What is low fusing porcelain? Achieve Superior Esthetics and Metal Integrity in PFM Restorations

- What are some features found in many modern dental ovens? Enhancing Precision Through Digital Integration

- Why is ceramic used in dentistry? For Aesthetic, Biocompatible, and Durable Restorations

- What is sintering in dentistry? Transform Zirconia into High-Strength Dental Restorations

- What is the shrinkage of zirconia during sintering? Mastering the 20-25% Dimensional Change

- What is the effect of high speed sintering on zirconia? Dramatically Faster Cycles with Critical Trade-offs

- What is the firing temperature for dental ceramics? Mastering the Critical Cycle for Strong, Aesthetic Restorations