The guideline you're likely referring to is the "Delta T" rule, a critical indicator for safe and effective agricultural spraying. While not commonly called the "delta 20 rule," Delta T is a calculation that combines temperature and humidity to determine the rate of spray droplet evaporation. The goal is to ensure the chemical has enough time to land on and be absorbed by the target, but not so much time that it runs off or drifts away.

The core principle is this: Delta T is a measure of a droplet's lifespan. It's not just about weather; it's a risk management tool that balances spray effectiveness against the potential for chemical waste, crop damage, and environmental harm.

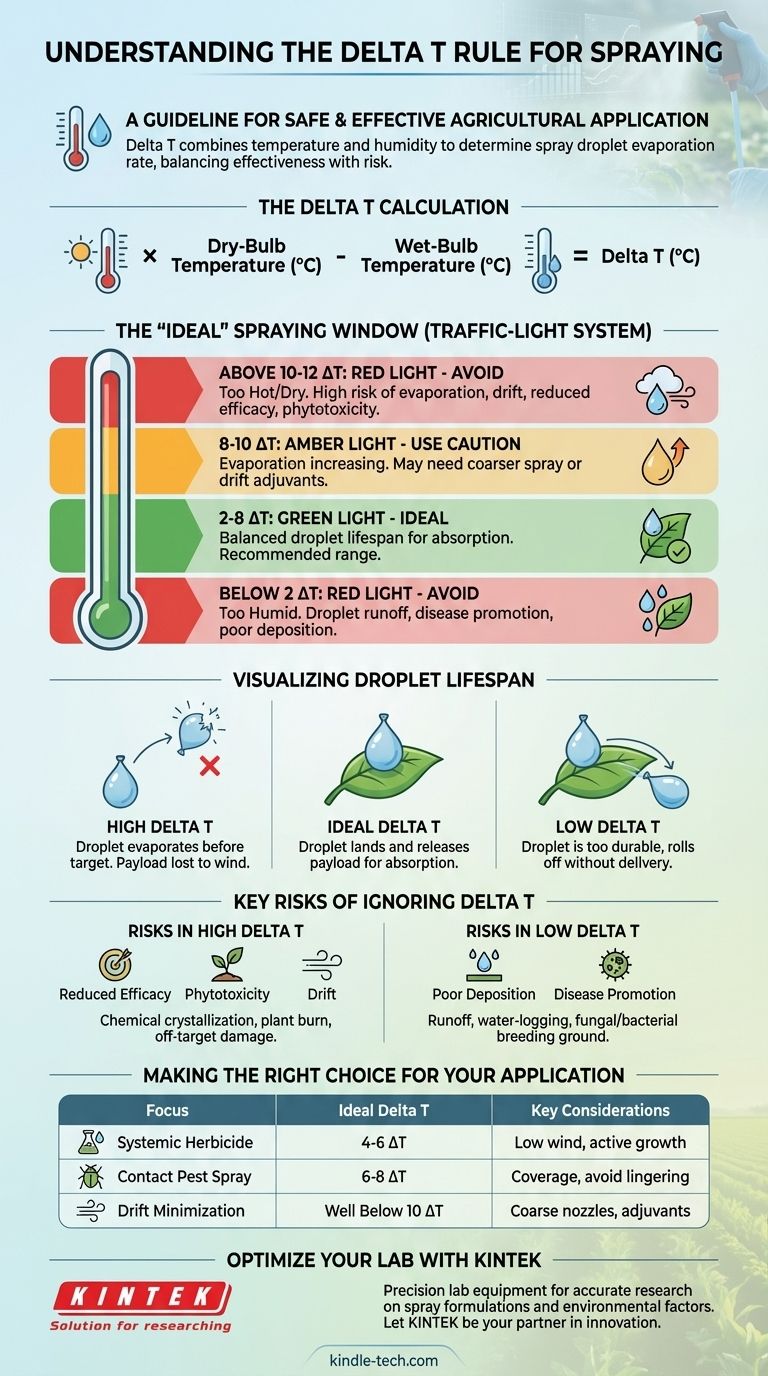

What is Delta T and Why Does It Matter?

At its core, Delta T helps you assess if your spray application will succeed or fail before you even start the engine. It provides a single number representing the atmosphere's capacity to evaporate water.

The Calculation and Its Meaning

Delta T is the difference between the dry-bulb temperature (the standard air temperature) and the wet-bulb temperature, all measured in Celsius. You don't need to calculate this manually; most weather meters used in agriculture (like a Kestrel) provide it automatically.

This single value tells you the potential for evaporation. A high Delta T means the air is hot and dry, and droplets will evaporate very quickly. A low Delta T means the air is cool and humid, and droplets will linger.

The "Ideal" Spraying Window

The Delta T value is used to define a traffic-light system for spraying. While specific crop or chemical labels may have stricter requirements, these are the generally accepted guidelines:

- Delta T Below 2 (Red Light): Conditions are too humid. Droplets will not evaporate quickly, leading to a high risk of them combining and running off the leaf surface. This also promotes fungal disease.

- Delta T Between 2 and 8 (Green Light): This is the ideal range for most applications. Droplets have a long enough lifespan to reach the target and be absorbed, but they still evaporate at a reasonable rate to prevent runoff.

- Delta T Between 8 and 10 (Amber Light): Spraying is acceptable, but caution is required. Evaporation is increasing, so you may need to use coarser spray qualities or drift-reducing adjuvants.

- Delta T Above 10-12 (Red Light): Conditions are too hot and/or dry. There is a very high risk of droplets evaporating before they even reach the target, drastically reducing efficacy and increasing the risk of drift.

Visualizing Droplet Lifespan

Think of a spray droplet as a tiny water balloon carrying a payload (the chemical). In a high Delta T environment, that balloon pops mid-air, and the payload is lost to the wind.

In a low Delta T environment, the balloon lands on the leaf but is so durable it rolls right off before the payload can be delivered. The goal is to have the balloon land on the leaf and gently release its contents for absorption.

Understanding the Trade-offs and Key Risks

Ignoring Delta T isn't just inefficient; it's risky. The consequences depend on which end of the spectrum you violate.

The Risks of Spraying in High Delta T

When evaporation is rapid, two primary dangers emerge:

- Reduced Efficacy: The water in the droplet evaporates, leaving behind a fine crystal of active ingredient that cannot be absorbed by the plant. This is a complete waste of time and money.

- Phytotoxicity and Drift: As water evaporates, the chemical concentration in the remaining droplet skyrockets. This highly concentrated droplet can burn the plant tissue, a phenomenon known as phytotoxicity. Furthermore, the vapor and fine particles can drift significant distances, damaging off-target crops or sensitive environmental areas.

The Risks of Spraying in Low Delta T

When conditions are too humid, the risks shift from evaporation to water-logging.

- Poor Deposition: With dew already on the leaf, new droplets may not stick, instead beading up and running off onto the soil.

- Disease Promotion: Lingering moisture on the leaf surface creates a perfect breeding ground for fungal and bacterial diseases, potentially causing a new problem while trying to solve another.

Making the Right Choice for Your Application

Delta T should never be viewed in isolation. It must be considered alongside wind speed, droplet size (nozzle selection), and the specific chemical's requirements.

- If your primary focus is applying a systemic herbicide: Aim for the Delta T sweet spot of 4-6 with low wind, when plants are actively growing, to ensure maximum absorption and translocation.

- If your primary focus is controlling a pest with a contact spray: A Delta T of 6-8 is often effective, ensuring the droplet has time to cover the target without lingering so long it promotes disease.

- If your primary focus is minimizing any risk of drift: Prioritize low wind speed first, then ensure your Delta T is well below 10. Consider using coarser nozzles and drift-reduction adjuvants to further mitigate risk.

By treating Delta T as a dynamic indicator of droplet survival, you can make smarter, safer, and more cost-effective application decisions.

Summary Table:

| Delta T Range (°C) | Spraying Condition | Key Risk |

|---|---|---|

| Below 2 | Red Light - Avoid | Droplet runoff, disease promotion |

| 2 - 8 | Green Light - Ideal | Balanced droplet lifespan for absorption |

| 8 - 10 | Amber Light - Use Caution | Increased evaporation, potential drift |

| Above 10-12 | Red Light - Avoid | High drift risk, reduced efficacy, phytotoxicity |

Optimize Your Lab's Agricultural Research with KINTEK

Understanding environmental factors like Delta T is key to developing effective agrochemicals. At KINTEK, we specialize in providing the high-precision lab equipment and consumables you need to simulate, test, and analyze real-world conditions in a controlled environment.

Whether you are formulating new sprays, testing droplet behavior, or ensuring application safety, our reliable equipment helps you achieve accurate and reproducible results.

Let KINTEK be your partner in innovation. Contact our experts today to find the perfect solutions for your laboratory's unique challenges.

Visual Guide

Related Products

- Evaporation Boat for Organic Matter

- Wall Mounted Water Distillation Unit

- Evaporation Crucible for Organic Matter

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Chiller Water Bath Cooling Circulator Low Temperature Constant Temperature Reaction Bath

People Also Ask

- Why is a powerful magnetic stirrer essential during photocatalytic degradation? Ensure Accurate Catalyst Performance

- What are the components of sintering? Master the 4-Step Process for Stronger Materials

- How does an industrial furnace work? Key Components and Applications Explained

- What temperature should Rotavap be? Master the Delta 20 Rule for Safe, Efficient Solvent Removal

- What is the meaning of sintering? A Guide to High-Strength, Complex Part Manufacturing

- What are the constituents of pyrolysis oil? Unlocking the Complex Chemistry of Bio-Oil

- What role does drying or curing equipment play in NSHPC synthesis? Ensuring Structural Precision in Porous Carbons

- What is a temperature control system for digital applications? The Key to Reliable Electronics Performance