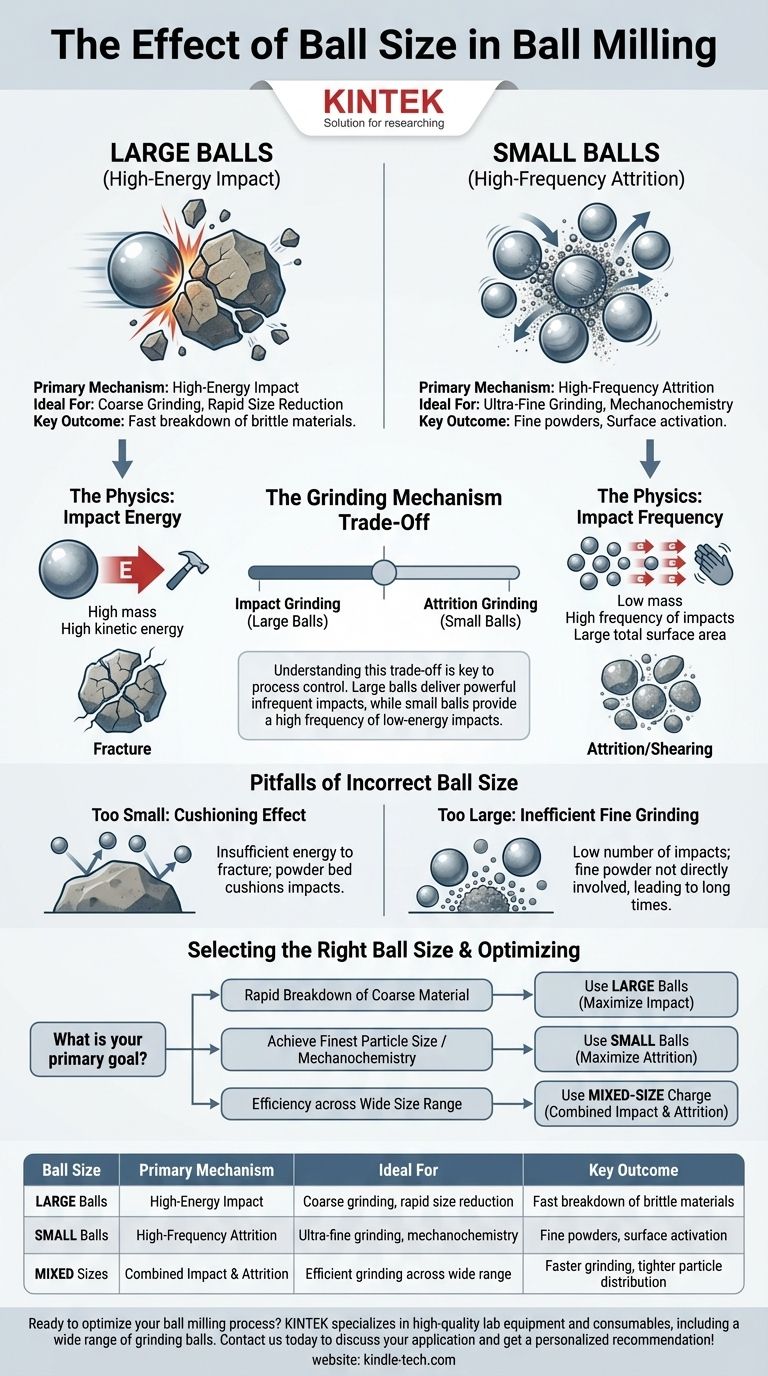

The size of your grinding media is one of the most critical parameters in a ball milling operation. In short, larger balls provide higher impact energy, which is ideal for breaking down coarse and hard materials quickly. Conversely, smaller balls offer a much higher surface area and number of impacts, which is superior for achieving a very fine final particle size and for promoting surface-level chemical reactions.

The choice between large and small balls is a strategic trade-off. Large balls deliver powerful but infrequent impacts for coarse grinding, while small balls provide a high frequency of low-energy impacts that excel at creating ultra-fine powders and activating surfaces. Understanding this trade-off is the key to process control.

The Physics of Energy Transfer

Ball milling is a process of transferring kinetic energy from the grinding media (the balls) to the material being milled. The size of the balls directly governs the nature and efficiency of this energy transfer.

Impact Energy vs. Impact Frequency

The grinding action in a mill is a combination of two primary events: impact and attrition (shearing).

Larger balls, having more mass, generate significantly higher kinetic energy per impact. This high energy is essential for causing fractures in large, robust particles.

Smaller balls, for the same total charge mass, result in a far greater number of individual balls. This dramatically increases the frequency of impacts and the total surface area of the grinding media, favoring attrition and surface polishing.

The Grinding Mechanism: Impact vs. Attrition

The size of your media determines which grinding mechanism will dominate your process.

Impact grinding occurs when a ball strikes a particle with enough force to cause it to shatter. This is the primary mechanism driven by large balls.

Attrition grinding is a shearing or rubbing action that occurs as balls slide past one another with material trapped between them. This is the dominant mechanism for small balls.

How Ball Size Dictates Milling Outcomes

The grinding mechanism you favor—impact or attrition—directly determines the results you can achieve.

For Rapid Size Reduction

If your goal is to quickly break down large, brittle feed material (e.g., from millimeter-scale to micron-scale), large balls are the correct choice.

Their high impact energy is necessary to initiate and propagate cracks through the material. Using small balls here would be like trying to break a large rock with a handful of pebbles; the energy is insufficient.

For Ultra-Fine Grinding

If your objective is to produce an extremely fine powder (sub-micron or nanometer scale), small balls are superior.

Once particles are small, high impact energy is not only unnecessary but can be inefficient. The high frequency of shearing events provided by small balls is far more effective at gradually reducing fine particles into even finer ones.

For Mechanochemical Synthesis

Mechanochemistry uses mechanical energy to drive chemical reactions. For these applications, small balls are often preferred.

The goal is not just size reduction but also surface activation. The high number of contact points and frequent, lower-energy impacts from small balls create more activated surfaces and reactive sites, promoting the desired chemical transformation.

Understanding the Trade-offs and Pitfalls

Selecting the wrong ball size can lead to extremely long milling times, poor results, and even process failure.

The Cushioning Effect

If the balls are too small relative to the feed particles, their impact energy will be insufficient to cause fracture. The powder bed will simply cushion the impacts, leading to little or no size reduction.

Inefficient Fine Grinding

If the balls are too large for fine grinding, the process becomes inefficient. The low number of impact events means that much of the fine powder is never directly involved in a grinding event, leading to a wide particle size distribution and long milling times to reduce the final fraction of particles.

Using a Mixed-Size Charge

For many applications, the most efficient approach is to use a distribution of ball sizes.

Large balls act to break down the coarse feed material, while the smaller balls work to grind the resulting smaller particles. This combines the benefits of both impact and attrition, often resulting in faster overall grinding and a tighter final particle size distribution.

Selecting the Right Ball Size for Your Goal

There is no single "best" ball size; the optimal choice is entirely dependent on your starting material and your desired outcome.

- If your primary focus is rapid breakdown of coarse material: Use larger grinding balls to maximize impact energy and fracture efficiency.

- If your primary focus is achieving the finest possible particle size: Use smaller grinding balls to maximize attrition and the frequency of grinding events.

- If your primary focus is efficiency across a wide size range: Use a mixed charge of large and small balls to combine high-energy impact with fine-grinding attrition.

- If your primary focus is driving a mechanochemical reaction: Favor smaller balls to increase the surface area of contact and the number of reaction-promoting impacts.

By understanding these principles of energy transfer, you can move from guesswork to a strategic selection of grinding media tailored to your specific outcome.

Summary Table:

| Ball Size | Primary Mechanism | Ideal For | Key Outcome |

|---|---|---|---|

| Large Balls | High-Energy Impact | Coarse grinding, rapid size reduction | Fast breakdown of brittle materials |

| Small Balls | High-Frequency Attrition | Ultra-fine grinding, mechanochemistry | Fine powders, surface activation |

| Mixed Sizes | Combined Impact & Attrition | Efficient grinding across a wide size range | Faster grinding, tighter particle distribution |

Ready to optimize your ball milling process? The right grinding media is critical for achieving your desired particle size and reaction efficiency. KINTEK specializes in high-quality lab equipment and consumables, including a wide range of grinding balls tailored for your specific laboratory needs. Our experts can help you select the perfect media to enhance your results. Contact us today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- How does the use of a planetary ball mill or manual grinding consumables affect alumina slurry? Master Nano-Scale Prep

- What core function does a high-power ball mill perform for nano-lead powder? Optimize Your Gamma-Ray Shielding

- What is the primary function of ball milling in the preparation of Al2O3/ZrO2 gradient ceramic tool materials? Key Mixing

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- What role does a high-energy ball mill play in the preparation of nanocatalysts? Advance Green Biodiesel Production

- What is the primary role of a planetary ball mill in preparing Ni-Cr-Co-Ti-V alloy powders for homogenization?

- Why use zirconia jars for Li2ZrCl6 synthesis? Ensure Purity & Energy for High-Performance Halide Electrolytes

- What is the function of a high-energy planetary ball mill in the synthesis of sodium-based oxysulfide glass? Expert Guide