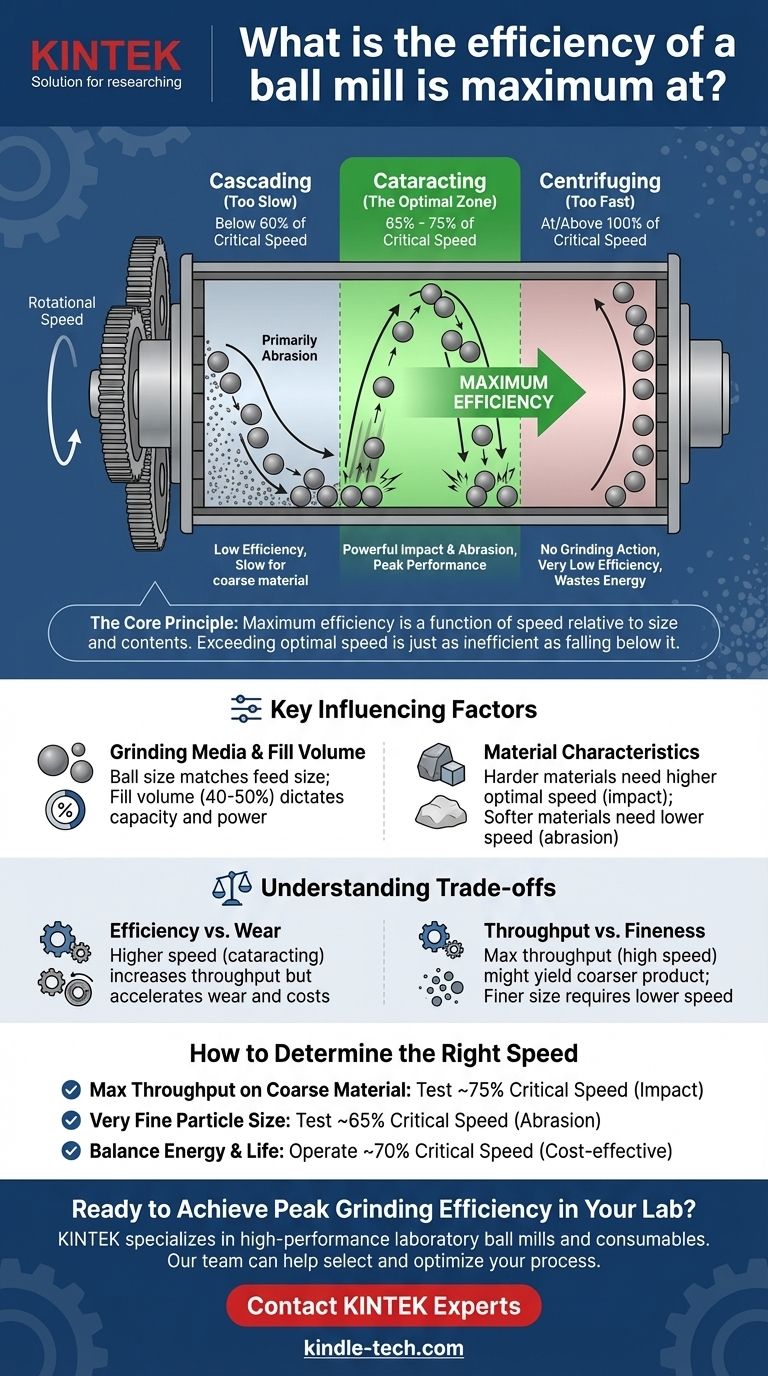

The efficiency of a ball mill is not maximized at a single, fixed number, but rather within an optimal operational range. This peak performance is achieved when the rotational speed of the mill creates a "cataracting" motion in the grinding media, a state that balances powerful impact with consistent abrasive forces. This typically occurs when the mill is operated between 65% and 75% of its calculated "critical speed."

The core principle is that maximum efficiency is a function of the mill's rotational speed relative to its size and contents. Exceeding the optimal speed range is just as inefficient as falling below it, as it prevents the grinding media from doing its job effectively.

The Core Principle: Understanding Mill Speed

The single most important variable for ball mill efficiency is its rotational speed. This speed dictates how the grinding media (the balls) behave inside the mill, which directly controls the grinding action. To understand this, we must first define the concept of "critical speed."

What is "Critical Speed"?

Critical speed is the theoretical rotational speed at which the outermost layer of grinding balls will centrifuge. This means they will be held against the mill's inner wall by centrifugal force, effectively ceasing all grinding action.

Operating at or above critical speed is highly inefficient because the media no longer tumbles or falls. Instead, it rotates with the mill, and no impact or shearing occurs.

The Three States of Grinding Media Motion

The efficiency of your grind is determined entirely by which of three states the media is in, all of which are controlled by speed.

1. Cascading (Too Slow)

At low speeds (typically below 60% of critical speed), the balls gently tumble over one another. This motion creates grinding action primarily through abrasion (rubbing). While effective for very fine grinding, the process is slow and lacks the high-impact force needed to break down larger particles efficiently.

2. Cataracting (The Optimal Zone)

Between 65% and 75% of critical speed, the balls are carried further up the side of the mill before detaching and falling onto the material below. This "cataracting" motion generates a powerful combination of impact (for breaking coarse particles) and abrasion (for reducing fine particles). This is the zone where most ball mills achieve maximum throughput and efficiency.

3. Centrifuging (Too Fast)

As the speed approaches and exceeds the critical speed, the grinding media becomes pinned to the mill liner. No tumbling or impact occurs, and grinding effectiveness drops to nearly zero. This state wastes enormous energy and causes excessive wear on the mill's lining.

Key Factors That Influence the Optimal Point

While speed is the primary lever, achieving maximum efficiency requires balancing it with several other operational factors.

Grinding Media and Fill Volume

The size of the grinding balls should be matched to the size of the material feed. Larger balls are needed for breaking down coarse feed, while smaller balls provide a greater surface area for fine grinding.

The fill volume (the percentage of the mill occupied by balls, typically 40-50%) also dictates how much material can be ground effectively and influences the power draw of the mill.

Material Characteristics

The hardness and structure of the material you are grinding are critical. Harder materials require more impact energy to fracture, suggesting an operating speed closer to the upper end of the optimal range (around 75% of critical speed).

Softer or more brittle materials may grind more efficiently at slightly lower speeds that emphasize a mix of abrasion and moderate impact.

Understanding the Trade-offs

Optimizing a ball mill is rarely about a single metric. You must balance competing goals.

Efficiency vs. Wear

Operating at higher speeds within the cataracting zone increases throughput but also accelerates the wear on both the grinding media and the mill liners. This increases operational costs and maintenance frequency.

Throughput vs. Fineness

Pushing for maximum throughput by increasing speed and feed rate may result in a coarser final product. Achieving a very fine, sub-micron particle size often requires lower speeds and longer grinding times to favor abrasive action over impact.

How to Determine the Right Speed for Your Process

There is no universal setting for a ball mill; the optimal point is specific to your material, equipment, and goals. Use the following guidelines as a starting point for your own process optimization.

- If your primary focus is maximum throughput on coarse material: Begin testing around 75% of the mill's critical speed to maximize impact forces.

- If your primary focus is achieving a very fine particle size: Start your process closer to 65% of critical speed to favor abrasive grinding action.

- If your primary focus is balancing energy cost and equipment life: Operate near the middle of the optimal range (around 70% of critical speed) and perform tests to find the most cost-effective point for your specific material.

Ultimately, peak efficiency is found through methodical testing centered on the principles of critical speed and grinding action.

Summary Table:

| Grinding Media Motion | Speed (% of Critical Speed) | Grinding Action | Efficiency |

|---|---|---|---|

| Cascading | Below ~60% | Primarily Abrasion | Low (Slow, inefficient for coarse material) |

| Cataracting (Optimal) | 65% - 75% | Powerful Impact & Abrasion | Maximum |

| Centrifuging | At/Above 100% | No Grinding Action | Very Low (Wastes Energy) |

Ready to Achieve Peak Grinding Efficiency in Your Lab?

Unlocking the full potential of your ball mill requires the right equipment and expert guidance. KINTEK specializes in high-performance laboratory ball mills and consumables designed for precise control and reliable operation. Our team can help you select the ideal mill and optimize your process for maximum throughput, particle size control, and cost-effectiveness.

Contact our experts today to discuss your specific grinding challenges and discover how KINTEK's solutions can enhance your lab's productivity and results.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is the key role of a planetary ball mill for IZO targets? Achieve Atomic-Level Uniformity in Material Preparation

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- How does a high-energy planetary ball mill facilitate the synthesis of sulfide glassy electrolytes? Achieve Amorphization