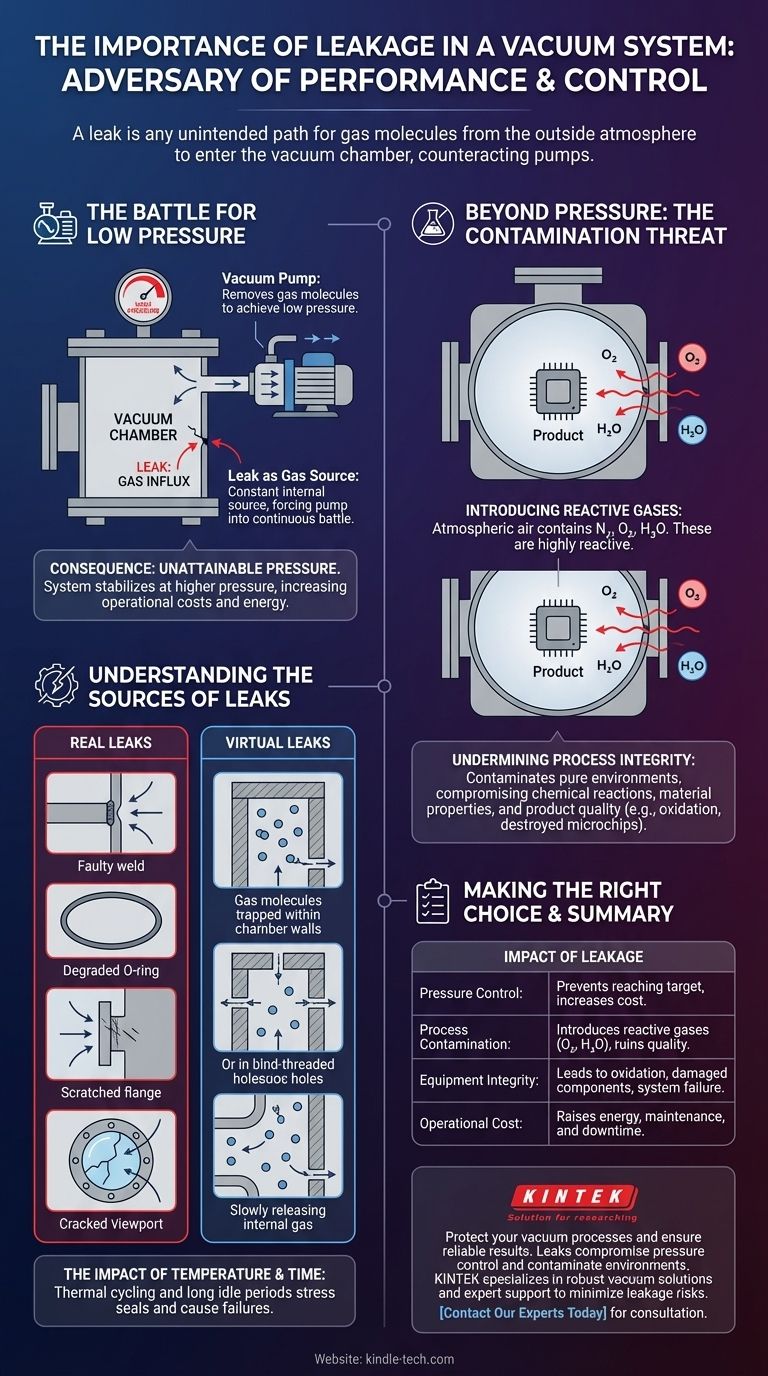

In a vacuum system, leakage is the primary adversary of performance and control. A leak is any unintended path that allows gas molecules from the outside atmosphere to enter the vacuum chamber. This influx of gas directly counteracts the work of the vacuum pumps, preventing the system from reaching its target pressure and contaminating the carefully controlled internal environment.

Leaks are not just an operational nuisance; they represent a fundamental failure of a vacuum system's core purpose. Understanding their impact is critical because they directly compromise process results, increase operational costs, and can ultimately damage sensitive equipment.

The Battle for Low Pressure

To grasp the importance of leakage, we must first understand the purpose of a vacuum. It is not about creating "suction" but about systematically removing gas molecules to create an environment with extremely low particle density, or low pressure.

The Role of the Vacuum Pump

A vacuum pump's job is to remove molecules from a sealed chamber. Its effectiveness is measured by its pumping speed—the volume of gas it can remove per unit of time.

In a perfect, leak-free system, the pump would eventually remove almost all molecules, achieving a very deep vacuum.

How a Leak Becomes a Gas Source

A leak acts as a constant, internal source of gas. The atmosphere, rich with nitrogen, oxygen, and water vapor, pushes its way through any available opening into the low-pressure chamber.

This forces the vacuum pump into a continuous battle. It must not only remove the gas that was initially in the chamber but also constantly fight the new gas streaming in through the leak.

The Consequence: Unattainable Pressure

If the rate of gas entering through the leak (the leak rate) is greater than or equal to the rate at which the pump can remove it, the system will never reach its desired low pressure. It will stabilize at a higher, unacceptable pressure, rendering the process useless.

Even a small leak significantly increases the time and energy required to reach the target pressure, driving up operational costs.

Beyond Pressure: The Contamination Threat

For many applications, the damage caused by leaks goes far beyond simply failing to reach a pressure setpoint. The composition of the gas that leaks in is often the more critical problem.

Introducing Reactive Gases

Atmospheric air is approximately 78% nitrogen, 21% oxygen, and contains significant water vapor. These molecules are highly reactive.

In processes like vacuum heat treating or thin-film coating, introducing oxygen or water can cause immediate oxidation, ruining the surface of a product. In semiconductor manufacturing, such contamination can destroy an entire batch of microchips.

Undermining Process Integrity

A vacuum is often used to create a pure environment that can then be backfilled with a specific, high-purity process gas like argon.

A leak contaminates this carefully controlled gas mixture. This compromises the chemical reactions, material properties, and overall quality of the final product.

Understanding the Sources of Leaks

Leaks can be notoriously difficult to find. They often arise from the physical realities of building and operating complex equipment, especially systems that undergo heating and cooling.

Real Leaks vs. Virtual Leaks

A real leak is a physical penetration through the chamber wall, such as a faulty weld, a degraded O-ring seal, a scratched flange surface, or a cracked viewport.

A virtual leak comes from gas trapped within the vacuum system itself. This can be moisture absorbed in chamber walls or gas trapped in blind-threaded holes that slowly bleeds out, mimicking a real leak.

The Impact of Temperature and Time

As noted in industrial settings, vacuum furnaces are highly susceptible to leaks during seasonal changes. This is due to thermal cycling. Temperature swings cause metal components to expand and contract, which can stress seals and fittings, causing them to fail.

Likewise, a furnace that has been idle for a long time may develop leaks. Elastomer O-rings can harden, take a "set," or degrade over time, losing their ability to create a proper seal when the system is put back into service.

Making the Right Choice for Your Goal

Managing leakage is a question of understanding your process requirements. A "good enough" vacuum for one application is a catastrophic failure for another.

- If your primary focus is high-purity processing (e.g., semiconductor, R&D, metallurgy): Your goal is minimizing contamination, so even minuscule leaks are unacceptable and require immediate detection and repair.

- If your primary focus is rough vacuum applications (e.g., mechanical holding, degassing, forming): You can often tolerate a higher leak rate as long as the system can maintain the target operational pressure without excessive pump runtime.

- If you are managing frequently cycled or long-idle equipment: Proactive maintenance, including regular inspection and replacement of seals before startup, is your most effective strategy to prevent costly downtime.

Ultimately, controlling leakage is about protecting the integrity of your process and ensuring the reliability of your results.

Summary Table:

| Impact of Leakage | Consequence |

|---|---|

| Pressure Control | Prevents reaching target pressure; increases pump runtime and cost. |

| Process Contamination | Introduces reactive gases (O₂, H₂O) that ruin product quality. |

| Equipment Integrity | Can lead to oxidation, damaged components, and system failure. |

| Operational Cost | Raises energy consumption, maintenance needs, and downtime. |

Protect your vacuum processes and ensure reliable results. Leaks compromise pressure control, contaminate sensitive environments, and damage equipment. KINTEK specializes in lab equipment and consumables, providing robust vacuum solutions and expert support to minimize leakage risks. Don't let leaks undermine your work—contact our experts today for a consultation on maintaining your system's integrity and performance.

Visual Guide

Related Products

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the temperature of arc melting? Harness Extreme Heat for Refractory Metals

- What is classification of heating furnace? A Guide to Selecting the Right Industrial Furnace

- Why is a high-vacuum high-temperature furnace necessary for Zr-4 alloy annealing? Ensure Superior Coating Adhesion

- Can you run your furnace with a generator? Power Your Heat Safely and Correctly

- Is brazing environmentally friendly? A Guide to Sustainable, Low-Impact Joining

- What is the main purpose of heat treatment? Tailor Material Properties for Peak Performance

- Which heat treatment process is a softening process? Understand Annealing for Superior Metal Workability

- Why is a laboratory vacuum oven necessary for LIPS preparation? Unlock ZIF-8 Pore Activation & Lubricant Infusion