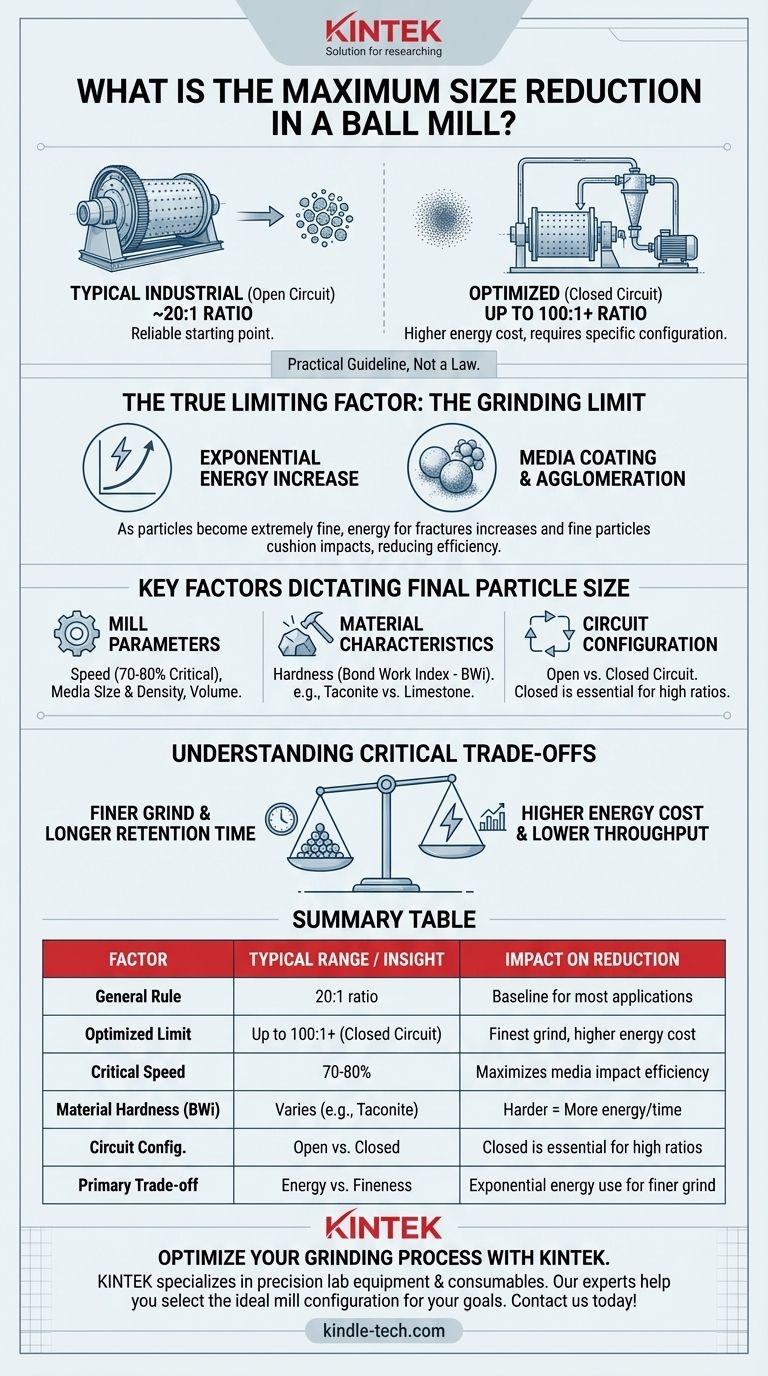

For a typical industrial ball mill, the maximum size reduction ratio is generally considered to be around 20:1. However, this is a practical guideline, not a physical law. Under optimized conditions and with specific circuit configurations, reduction ratios can reach as high as 100:1 or even more, but this comes with significant trade-offs in energy consumption and throughput.

The concept of a single "maximum" size reduction is misleading. The true limit is a dynamic balance between the material's properties, the mill's configuration, and the economic point of diminishing returns, where the energy required for further grinding becomes prohibitive.

Deconstructing the "Reduction Ratio"

The reduction ratio is a simple comparison of the feed particle size to the product particle size. While useful for initial estimates, understanding what governs this ratio is far more important for any practical application.

The Common Rule of Thumb

For most general-purpose grinding circuits, a 20:1 ratio is a reliable starting point for design and expectation. This means if you feed 20 mm material into the mill, you can reasonably expect to achieve a product where 80% of the particles are smaller than 1 mm.

Pushing the Operational Limits

Achieving a 100:1 reduction ratio is possible but requires a highly optimized system. This typically involves using a closed-circuit grinding setup, where the mill's output is sent to a classifier (like a hydrocyclone) that separates fine particles from coarse ones.

The fine particles exit the system as the final product, while the oversized coarse particles are sent back to the mill for further grinding. This prevents the mill from wasting energy over-grinding particles that are already small enough.

The True Limiting Factor: The Grinding Limit

As particles become extremely fine (typically entering the micron range), two phenomena create a practical limit.

First, the energy required to create new fractures increases exponentially. Second, the fine particles can begin to coat the grinding media (the balls), cushioning the impacts and drastically reducing grinding efficiency. At this point, the material may even start to agglomerate, effectively stopping any further size reduction.

Key Factors That Dictate Final Particle Size

The final particle size you can achieve is not a single number but the result of several interconnected variables. Controlling these is the key to efficient grinding.

Mill Operating Parameters

The speed of the mill is critical. It's typically operated at 70-80% of its "critical speed"—the theoretical speed at which the grinding media would centrifuge and cling to the mill shell. This range maximizes the cascading and cataracting actions that are responsible for grinding.

The size, density, and volume of the grinding media also play a central role. Larger, denser balls are used for breaking coarse feed, while smaller balls provide the greater surface area needed for finer grinding.

Material Characteristics

The inherent properties of the material being ground are paramount. The Bond Work Index (BWi) is a standard measure of a material's hardness and resistance to grinding.

A hard material like taconite will require significantly more energy and retention time to achieve the same size reduction as a softer material like limestone.

Circuit Configuration

As mentioned, a closed-circuit system is far more efficient and capable of producing a finer product than an open-circuit one. By continuously removing properly sized particles, the closed circuit allows the mill to focus its energy exclusively on the material that still needs to be ground.

Understanding the Critical Trade-offs

Optimizing a grinding circuit is always an exercise in balancing competing priorities. Understanding these trade-offs is essential for making sound operational decisions.

Energy vs. Fineness

This is the most fundamental trade-off. Grinding is an energy-intensive process, and the energy cost rises exponentially as the target particle size decreases. Doubling the fineness of the product can often more than double the energy consumption.

Throughput vs. Retention Time

To achieve a finer grind, the material must spend more time inside the mill (longer retention time). This directly reduces the overall processing rate, or throughput, of the system. You must decide whether a finer product is worth a lower production rate.

Making the Right Choice for Your Goal

Your optimal setup depends entirely on your primary objective. There is no single "best" way to operate a ball mill; there is only the best way for your specific goal.

- If your primary focus is maximizing throughput for a coarse product: Operate in an open circuit or with a coarse classifier setting, use larger grinding media, and maintain a high feed rate.

- If your primary focus is achieving a very fine, specialized product: You must use a closed-circuit system with an efficient classifier, smaller grinding media, and be prepared for higher energy costs and lower production rates.

- If your primary focus is optimizing energy efficiency: Focus on closed-circuit operation, maintain the correct media charge level, and precisely control the mill speed and slurry density to avoid wasting power.

Ultimately, the limitations of a ball mill are defined less by physics and more by economics and process requirements.

Summary Table:

| Factor | Typical Range / Key Insight | Impact on Size Reduction |

|---|---|---|

| General Rule of Thumb | 20:1 reduction ratio | Baseline for most industrial applications |

| Optimized Limit (Closed Circuit) | Up to 100:1 or more | Achieves finest grind but with higher energy cost |

| Critical Operating Speed | 70-80% of critical speed | Maximizes grinding media impact efficiency |

| Material Hardness (Bond Work Index) | Varies by material (e.g., Taconite vs. Limestone) | Harder materials require more energy and time |

| Circuit Configuration | Open vs. Closed Circuit | Closed circuit is essential for high reduction ratios |

| Primary Trade-off | Energy Consumption vs. Particle Fineness | Finer grinding exponentially increases energy use |

Optimize Your Grinding Process with KINTEK

Are you looking to maximize throughput, achieve a super-fine product, or improve energy efficiency in your lab or production line? The right ball mill configuration is key to hitting your targets.

KINTEK specializes in precision lab equipment and consumables, offering solutions tailored to your specific grinding needs. Our experts can help you select the ideal mill, media, and circuit configuration to balance fineness, throughput, and cost-effectiveness.

Contact us today to discuss your application and let KINTEK provide the reliable equipment and expert support you need for superior size reduction results.

Get in touch with our grinding experts now!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the role of alumina ball milling jars in Cu-Ti3SiC2 mixing? Ensure Purity and Homogeneity

- What is the primary function of a planetary ball mill in LBF preparation? Master High-Energy Mechanochemical Synthesis

- Why is a planetary ball mill with zirconia grinding balls used for cellulose pretreatment? Unlock Catalytic Hydrolysis

- What role does a planetary ball mill play in graphite-LPS composite anodes? Expert Microstructural Engineering

- Why is R-HEBM used for high-entropy carbides? Produce Ultrafine Powders via Low-Temperature In-Situ Synthesis

- What is the role of a high-energy planetary ball mill in mechanical alloying? Master High-Entropy Alloy Synthesis

- What is the function of a planetary ball mill with stabilized zirconia beads? Optimize Rare-Earth Perovskite Synthesis

- What are the parameters of a planetary ball mill? Master Speed, Time, and Media for Perfect Grinding