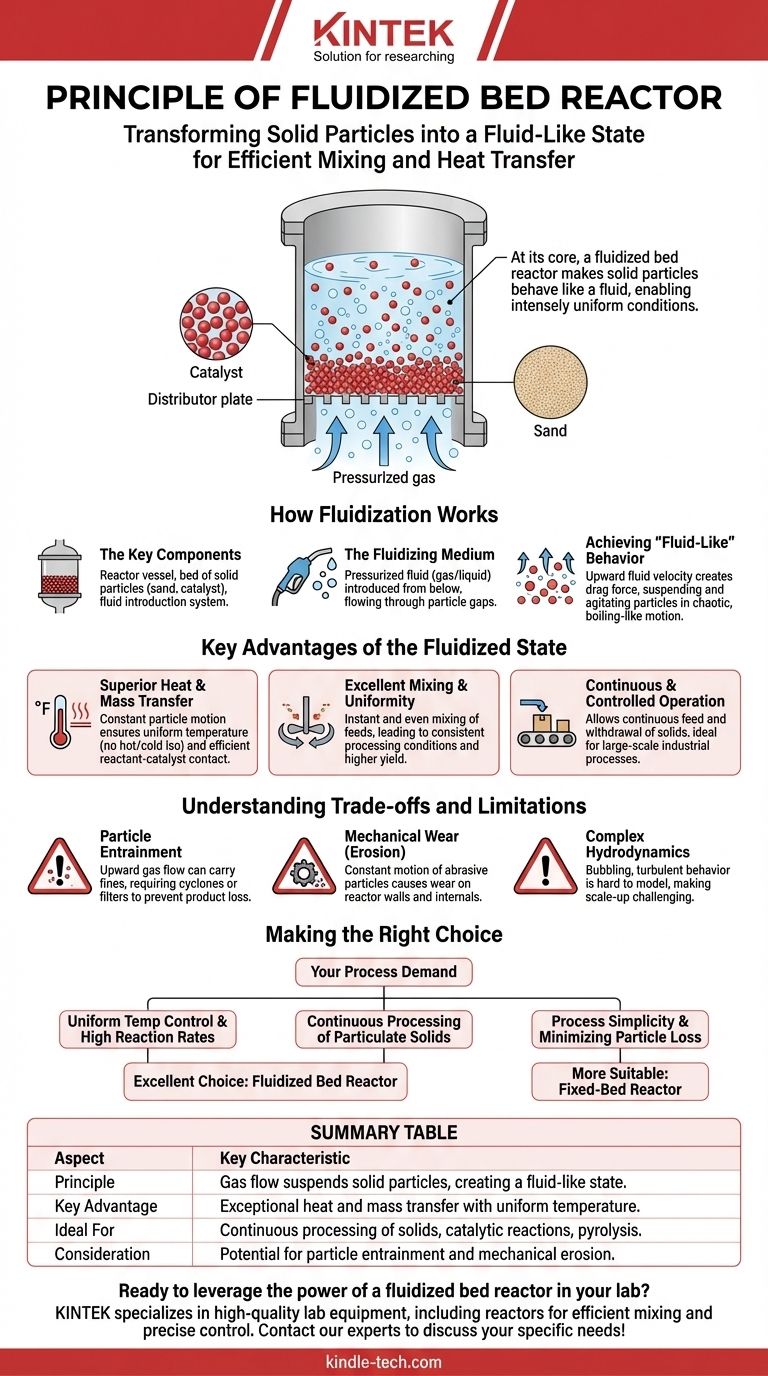

At its core, a fluidized bed reactor is a device that makes a bed of solid particles behave like a fluid. This is achieved by passing a pressurized fluid, typically a gas, up through the solid particulate medium at a high enough velocity to suspend the particles. This suspension and agitation create a "fluidized" state, which enables exceptionally efficient mixing and heat transfer throughout the reactor.

The central principle of a fluidized bed reactor is not just about suspending particles, but about leveraging that fluid-like state to create intensely uniform conditions. This uniformity in temperature and composition is the key to its effectiveness in a wide range of chemical and physical processes.

How Fluidization Works: From Solid to Fluid-Like State

To understand the reactor, you must first understand the phenomenon of fluidization. It is a physical process that transforms the properties of the system.

The Key Components

A typical fluidized bed reactor consists of the reactor vessel, a bed of solid particles, and a system for introducing a fluid from below. The solids are often an inert material like sand for heat transfer or a catalyst to facilitate a reaction.

The Fluidizing Medium

A gas or liquid is pumped through a distributor plate at the bottom of the reactor. This fluid flows upward through the gaps between the solid particles. Common gases include air for combustion or nitrogen for creating an inert atmosphere to prevent unwanted side reactions.

Achieving the "Fluid-Like" Behavior

As the velocity of the upward-flowing fluid increases, it begins to exert a drag force on the particles. When this force equals the downward gravitational force, the particles become suspended. As velocity increases further, the bed expands and the particles begin to move around chaotically, bubbling and mixing vigorously, closely resembling a boiling liquid.

Key Advantages of the Fluidized State

The unique behavior of the fluidized bed provides several significant operational advantages over other reactor types, such as fixed-bed reactors.

Superior Heat and Mass Transfer

The constant, rapid motion of the particles ensures that temperature is extremely uniform throughout the reactor. This prevents hot spots or cold spots, which is critical for controlling chemical reactions and ensuring consistent product quality. The same principle applies to mass transfer, ensuring reactants are efficiently brought into contact with catalyst particles.

Excellent Mixing and Uniformity

The vigorous agitation guarantees that any material fed into the reactor, such as biomass for pyrolysis, is mixed almost instantly and evenly. This leads to consistent processing conditions for every particle, increasing the yield of desired products like bio-oils and gases.

Continuous and Controlled Operation

The fluid-like nature of the bed allows for solids to be fed and withdrawn continuously, making it ideal for large-scale industrial processes. As seen in applications like fluidized bed jet mills, the system can also transport particles for classification and recycling within the process itself.

Understanding the Trade-offs and Limitations

While powerful, this technology is not without its challenges. An objective assessment requires understanding its potential downsides.

Particle Entrainment

The upward flow of gas can carry fine particles out of the reactor. This requires the use of downstream separation equipment, such as cyclones or bag filters, to capture the entrained material and prevent product loss or environmental release.

Mechanical Wear (Erosion)

The constant motion of abrasive particles can cause significant wear and tear on the internal components of the reactor, such as the walls and heat transfer tubes. This erosion can be a limiting factor in the reactor's lifespan and maintenance schedule.

Complex Hydrodynamics

The behavior of the bubbling, turbulent bed is complex and can be difficult to model accurately. This makes scaling up a design from a small pilot plant to a large industrial unit more challenging compared to simpler reactor designs like fixed-bed or packed-bed reactors.

Making the Right Choice for Your Process

Your decision to use a fluidized bed reactor should be based on the specific demands of your application.

- If your primary focus is uniform temperature control and high reaction rates: A fluidized bed reactor is an excellent choice due to its superior heat transfer and mixing properties, which are ideal for sensitive catalytic reactions.

- If your primary focus is processing particulate solids continuously: The fluid-like state allows for efficient handling and uniform processing of materials like biomass, minerals, or powders.

- If your primary focus is process simplicity and minimizing particle loss: A fixed-bed reactor might be more suitable, as it avoids the complexities of fluidization hydrodynamics and particle entrainment.

Understanding this core principle empowers you to leverage its unique advantages for highly efficient and uniform material processing.

Summary Table:

| Aspect | Key Characteristic |

|---|---|

| Principle | Gas flow suspends solid particles, creating a fluid-like state. |

| Key Advantage | Exceptional heat and mass transfer with uniform temperature. |

| Ideal For | Continuous processing of solids, catalytic reactions, pyrolysis. |

| Consideration | Potential for particle entrainment and mechanical erosion. |

Ready to leverage the power of a fluidized bed reactor in your lab? KINTEK specializes in high-quality lab equipment, including reactors designed for efficient mixing and precise temperature control. Whether you're developing catalytic processes or optimizing material synthesis, our solutions are built for performance and reliability. Contact our experts today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is energy from biomass pyrolysis? Turn Organic Waste into Syngas, Bio-oil, and Biochar

- What role does a rotary kiln play in the incineration treatment of waste composite materials? Energy & Volume Solutions

- What are the disadvantages of rotary kiln incinerators? High Costs and Environmental Challenges

- What is the process of fast pyrolysis? A Rapid Pathway to Bio-Oil from Biomass

- What are the emissions of pyrolysis? Transforming Waste into Valuable Products, Not Pollution

- What are the heating sources for pyrolysis? Direct vs. Indirect Methods for Optimal Product Yield

- What is the temperature for activated carbon regeneration? Key Ranges from 220°C to 900°C

- What is conventional pyrolysis? A Guide to Slow Pyrolysis for Biochar Production