At its core, the purpose of an optical coating is to precisely control how light interacts with the surface of an optical component like a lens or mirror. These coatings are microscopically thin layers of specific materials deposited onto a surface to change the way it reflects, transmits, or absorbs different wavelengths of light. This manipulation allows a simple piece of glass to perform a highly specialized function.

The essential takeaway is that optical coatings leverage the physics of thin-film interference to alter a material's natural optical properties. This transforms a standard component into a high-performance tool designed to enhance transmission, maximize reflection, or filter light with incredible precision.

How Optical Coatings Manipulate Light

The function of an optical coating is not based on the bulk properties of its materials, but on the interactions that happen at the boundaries between its extremely thin layers.

The Principle of Thin-Film Interference

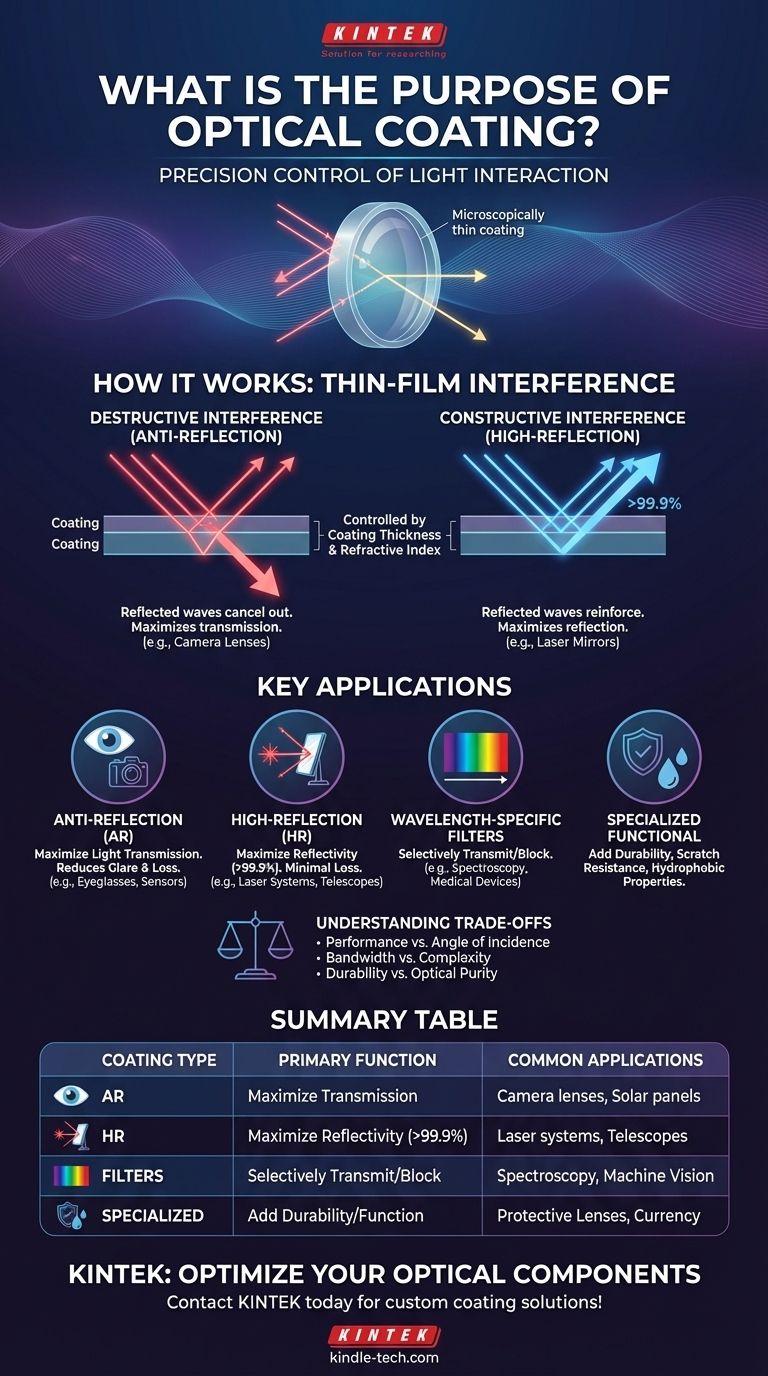

The core mechanism behind most optical coatings is thin-film interference. When light strikes a coated surface, some of it reflects off the top surface of the coating, while some enters the coating and reflects off the bottom surface (at the coating-substrate boundary).

These two reflected light waves then interfere with each other. By carefully controlling the thickness of the coating layer and the refractive index of the material used, engineers can dictate whether this interference is constructive or destructive.

Destructive vs. Constructive Interference

Destructive interference occurs when the reflected waves are out of phase, causing them to cancel each other out. This is the principle behind anti-reflection coatings, which minimize reflections and maximize the amount of light passing through the component.

Constructive interference occurs when the reflected waves are in phase, causing them to reinforce each other. This is the basis for high-reflection coatings, which can create mirrors that reflect over 99.9% of specific light wavelengths.

Key Applications of Optical Coatings

By mastering interference, we can create coatings for a wide range of highly specific tasks, turning a simple optical substrate into a precision instrument.

Anti-Reflection (AR) Coatings

The goal of an AR coating is to maximize light transmission. Uncoated glass reflects about 4% of light per surface. In a complex camera lens with many elements, this cumulative light loss can severely degrade image brightness and contrast.

AR coatings are critical for applications like eyeglasses, camera lenses, solar panels, and display screens where maximizing throughput and reducing glare is essential.

High-Reflection (HR) Coatings

The goal of an HR coating is to maximize reflectivity. While a standard aluminum mirror reflects about 85-90% of light, a dielectric HR coating can achieve reflectivities exceeding 99.9% for a specific wavelength range.

These are indispensable for laser systems, high-end telescopes, and other sensitive instruments where light must be redirected with minimal loss.

Wavelength-Specific Filters

These coatings are designed to selectively transmit or block certain wavelengths (colors) of light.

Examples include cut-off filters that block everything below or above a certain wavelength, and band-pass filters that only allow a narrow range of wavelengths to pass through. They are fundamental to scientific analysis, medical devices, and machine vision.

Specialized Functional Coatings

Beyond the primary types, coatings can provide other functions. Anti-counterfeiting films on currency use coatings that change color depending on the viewing angle. Other coatings can add durability, scratch resistance, or hydrophobic (water-repelling) properties to an optical surface.

Understanding the Trade-offs

Applying an optical coating is a balancing act; improving one characteristic can often come at the expense of another.

Performance vs. Angle of Incidence

Coatings are typically optimized for light that strikes the surface at a specific angle (often perpendicular). As the angle of incidence changes, the path length of light through the coating also changes, shifting the interference effect and degrading the coating's performance.

Bandwidth vs. Complexity

A coating designed to work for a single wavelength (like a laser mirror) can be relatively simple. A broadband coating that must maintain its properties across a wide spectrum of light (like a camera lens AR coating) requires many more layers, making it significantly more complex and expensive to design and manufacture.

Durability vs. Optical Purity

The materials with the best optical properties are not always the most robust. There is often a trade-off between a coating's environmental durability (resistance to abrasion, temperature, and humidity) and its peak optical performance.

Making the Right Choice for Your Goal

Selecting a coating requires a clear understanding of the primary objective for your optical system.

- If your primary focus is maximizing light throughput (e.g., camera lenses, sensors): You require an Anti-Reflection (AR) coating designed for the specific wavelength range of your application.

- If your primary focus is redirecting light with minimal loss (e.g., laser cavities, beam steering): You need a High-Reflection (HR) coating, often a dielectric mirror, optimized for your laser's specific wavelength and angle of incidence.

- If your primary focus is isolating or blocking specific colors (e.g., fluorescence microscopy, spectroscopy): You need a specialized filter coating, such as a band-pass, long-pass, or short-pass filter.

Ultimately, optical coatings are what elevate functional optics into high-performance, purpose-built systems.

Summary Table:

| Coating Type | Primary Function | Common Applications |

|---|---|---|

| Anti-Reflection (AR) | Maximize light transmission | Camera lenses, eyeglasses, solar panels |

| High-Reflection (HR) | Maximize reflectivity (>99.9%) | Laser systems, telescopes |

| Wavelength Filters | Selectively transmit/block specific wavelengths | Spectroscopy, medical devices, machine vision |

| Specialized Coatings | Add durability, scratch resistance, anti-counterfeiting | Currency, protective lenses |

Ready to optimize your optical components with precision coatings?

At KINTEK, we specialize in high-performance lab equipment and consumables for optical applications. Whether you need custom anti-reflection coatings for sensor systems, high-reflection mirrors for laser setups, or specialized filters for analytical instruments, our expertise ensures maximum light control and system efficiency.

We help researchers, engineers, and laboratories achieve superior optical performance through tailored coating solutions. Let us enhance your project's accuracy and reliability.

Contact KINTEK today to discuss your specific optical coating requirements!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

People Also Ask

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers