For a standard sieve analysis, the generally recommended sample size is between 25 and 100 grams. However, this is only a starting point. The optimal size is not a fixed number but is critically dependent on the material's characteristics and the mesh sizes used, as using a sample that is too large can significantly compromise the accuracy of your results.

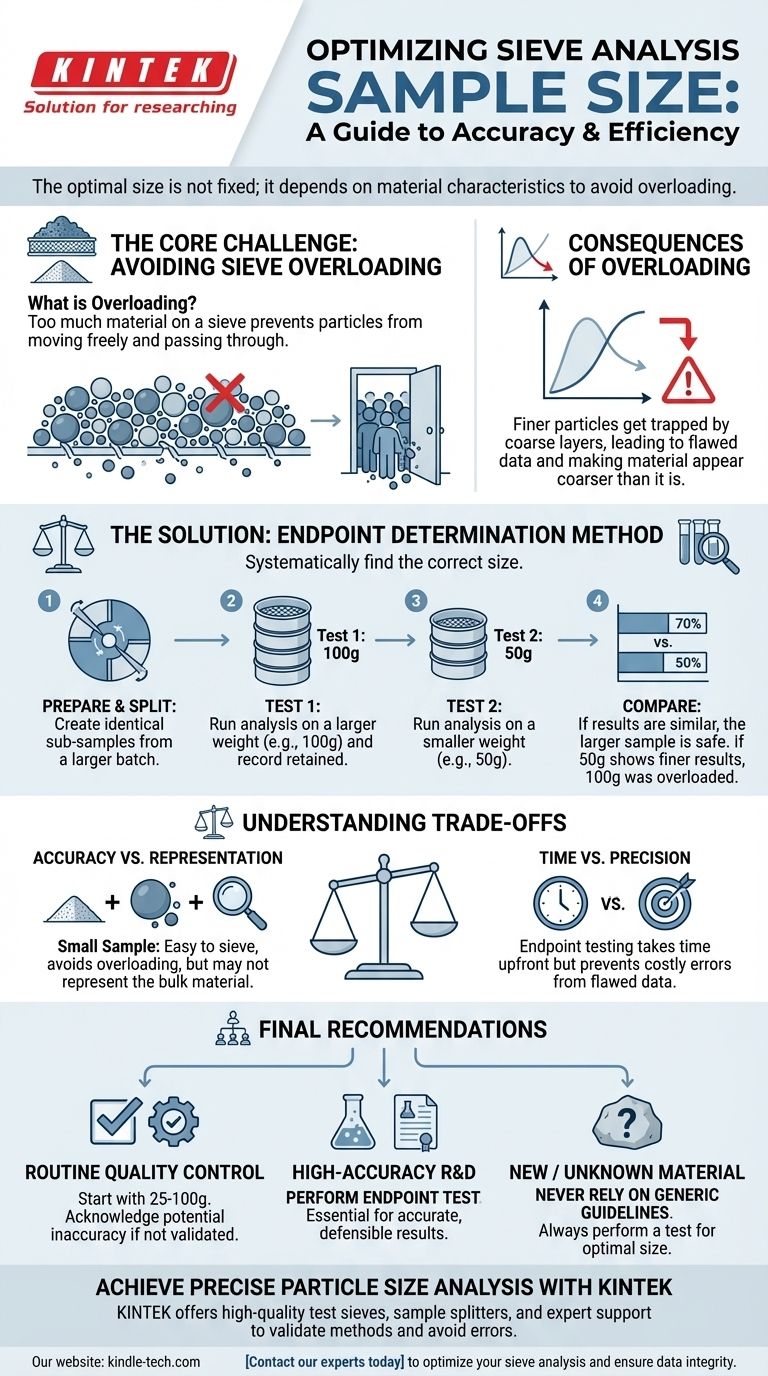

The central challenge in selecting a sample size is preventing "sieve overloading." An overloaded sieve prevents particles from having a fair chance to pass through the mesh, which skews your data and can lead to incorrect conclusions about your material's particle size distribution.

The Core Principle: Avoiding Sieve Overloading

What is Sieve Overloading?

Sieve overloading occurs when the volume of material on a sieve is too great. This creates a bed of particles so thick that individual particles cannot move freely and present themselves to the sieve openings.

Think of it like a crowded doorway after a concert. If too many people try to exit at once, they create a jam, and no one can get through efficiently, even if they are small enough to fit through the door. The same happens to particles on an overloaded sieve.

The Consequence of an Overloaded Sieve

The direct consequence of overloading is inaccurate results. Finer particles become trapped by the layer of coarser particles above them and are not given the opportunity to pass through to the next sieve in the stack.

This systematic error makes your material appear coarser than it actually is, leading to a skewed particle size distribution curve and flawed data.

The Problem with Samples That Are Too Small

While overloading is the primary concern, a sample that is too small also presents a risk. An extremely small sample may not be statistically representative of the entire batch of material, leading to results that are not repeatable or valid.

How to Determine the Optimal Sample Size

The Endpoint Determination Method

The most reliable way to establish the correct sample size for your specific material is through a systematic test. This procedure validates that your sample weight is not causing overloading.

- Prepare a Representative Sample: Begin with a larger sample and use a rotary sample splitter to create several smaller, identical subsamples. This is crucial for consistency.

- Test the First Weight: Run a complete sieve analysis on a sample of a given weight, for example, 100 grams. Carefully record the weight of material retained on each sieve.

- Test a Smaller Weight: Run a second analysis on a smaller sample, for example, 50 grams. Again, record the weight of material on each sieve.

- Compare the Results: Calculate the percentage of material retained on each sieve for both tests. If the percentages are nearly identical, the 100-gram sample was not overloaded, and it is a safe weight to use.

If the 50-gram sample shows a significantly higher percentage of material passing through the finer sieves, it indicates the 100-gram sample was overloaded. You should then repeat the test with an even smaller sample (e.g., 25 grams) to find the point where results stabilize.

Understanding the Trade-offs

Accuracy vs. Representation

There is a fundamental trade-off between ensuring accuracy on the sieve and ensuring the sample represents the bulk material.

A very small sample is easy to sieve and avoids overloading, but it may not capture the full diversity of particles in a large batch. A larger sample is more representative but carries a high risk of overloading and producing false data. The endpoint determination method is how you find the balance.

Time vs. Precision

Performing endpoint tests requires additional time and effort upfront. However, this initial investment prevents the far greater cost of making critical process, quality, or research decisions based on flawed data.

Final Recommendations for Your Analysis

Choosing your sample size depends directly on the goal and required rigor of your analysis.

- If your primary focus is routine, quick quality control: Starting with a consistent weight in the 25-100g range can be acceptable, but you must acknowledge the potential for inaccuracy if this weight has not been validated.

- If your primary focus is high-accuracy research or process development: You must perform an endpoint determination test to scientifically validate your sample size and ensure your results are accurate and defensible.

- If you are working with a new material: Never rely on a generic guideline. Always perform a test to determine the optimal sample mass for that specific material.

By validating your sample size, you ensure the fundamental integrity of your particle size analysis.

Summary Table:

| Scenario | Recommended Sample Size | Key Consideration |

|---|---|---|

| Routine Quality Control | 25 - 100 grams | Potential for inaccuracy if not validated |

| High-Accuracy R&D | Determined by Endpoint Test | Scientifically validated for defensible results |

| New/Unknown Material | Determined by Endpoint Test | Essential for material-specific accuracy |

Achieve precise and reliable particle size analysis with KINTEK.

Inaccurate sieve analysis due to sample overload can lead to costly errors in your quality control or research. KINTEK specializes in providing the right laboratory equipment and expert support to ensure your processes are built on a foundation of accurate data.

We offer:

- High-quality test sieves and sample splitters for representative sampling.

- Expert guidance to help you validate your methods and avoid common pitfalls like overloading.

Don't let an incorrect sample size compromise your results. Contact our experts today to optimize your sieve analysis and ensure data integrity.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis