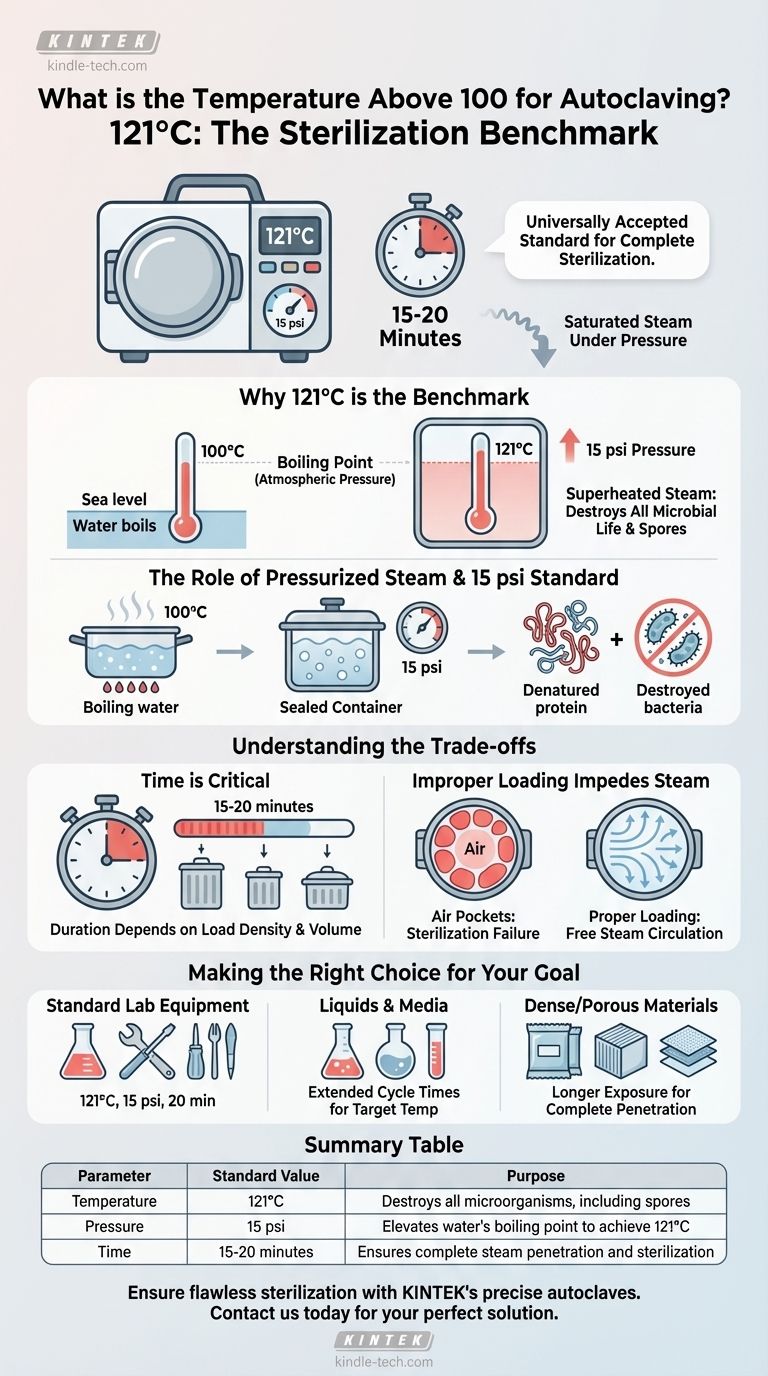

The standard temperature for autoclaving is 121°C. This specific temperature, held for a minimum of 15-20 minutes, is the universally accepted standard for ensuring the complete sterilization of most laboratory and medical equipment. It is achieved by using saturated steam under a pressure of approximately 15 pounds per square inch (psi).

The key isn't just achieving a high temperature, but achieving it with saturated steam under pressure. This combination is what effectively destroys all forms of microbial life, including resilient bacterial spores.

Why 121°C is the Benchmark

The goal of autoclaving isn't just to heat things up; it's to achieve sterilization. This means killing all microorganisms, including the toughest forms like bacterial endospores, which can survive boiling water (100°C) at normal atmospheric pressure.

The Role of Pressurized Steam

At sea level, water boils at 100°C. No matter how much you heat it, the temperature of the water won't rise above this point.

To increase the temperature of steam past 100°C, you must increase the pressure. Inside a sealed autoclave, as pressure builds, the boiling point of water rises.

The 15 psi Standard

A pressure of 15 psi above atmospheric pressure is the industry standard. This specific pressure level elevates the boiling point of water to 121°C.

This superheated, saturated steam is the active sterilizing agent. It rapidly penetrates materials and denatures essential proteins and enzymes within microorganisms, ensuring their destruction.

Understanding the Trade-offs

Simply reaching 121°C is not enough to guarantee sterilization. Several factors can compromise the effectiveness of the process, leading to a false sense of security.

Time is a Critical Factor

The duration of the cycle is just as important as the temperature. The standard 15-20 minute cycle begins only after the internal chamber has reached 121°C.

Larger or denser loads require longer sterilization times to ensure the steam fully penetrates every surface.

Improper Loading Impedes Steam

If an autoclave is packed too tightly, it creates air pockets that prevent steam from reaching all surfaces. This is a common cause of sterilization failure.

Items must be arranged to allow for free circulation of steam throughout the entire chamber.

Making the Right Choice for Your Goal

The standard of 121°C is effective for the vast majority of applications, but the specific cycle parameters depend on what you are sterilizing.

- For standard lab equipment (glassware, metal instruments): The 121°C, 15 psi, 20-minute cycle is the established and reliable benchmark.

- For liquids and media: Cycle times may need to be extended to ensure the liquid volume reaches the target temperature and is held there for the required duration.

- For dense or porous materials: A longer exposure time is necessary to allow for complete steam penetration throughout the load.

Ultimately, successful autoclaving depends on the precise and consistent relationship between temperature, pressure, and time.

Summary Table:

| Parameter | Standard Value | Purpose |

|---|---|---|

| Temperature | 121°C | Destroys all microorganisms, including bacterial spores |

| Pressure | 15 psi | Elevates water's boiling point to achieve 121°C |

| Time | 15-20 minutes | Ensures complete steam penetration and sterilization |

Ensure your lab's sterilization process is flawless with KINTEK's reliable autoclaves. Our equipment delivers precise temperature and pressure control, guaranteeing effective sterilization for your laboratory instruments, glassware, and media. Contact us today to find the perfect autoclave solution for your lab's specific needs and achieve uncompromising sterility with every cycle.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- Why is a laboratory autoclave necessary for Postgate Medium B (PMB)? Ensure Pure SRB Cultures & Accurate MIC Research

- How does a slow strain rate testing system integrated with an autoclave facilitate material research? | KINTEK

- How is an autoclave used to sterilize various requirement in the laboratory? A Guide to Effective Steam Sterilization

- Can you autoclave surgical instruments? Master the Gold Standard for Sterilization

- What is an autoclave in microbiology? The Key to Sterile, Safe, and Valid Lab Results

- What role does a static autoclave play in PWSCC testing of Alloy 600? Simulating Extreme Reactor Conditions

- How does an industrial autoclave work? Unlock the Power of High-Pressure Steam for Sterilization

- Why Use a PTFE-Lined Stainless Steel Autoclave for CeO2 Nanosheets? Essential Equipment for Purity & Control