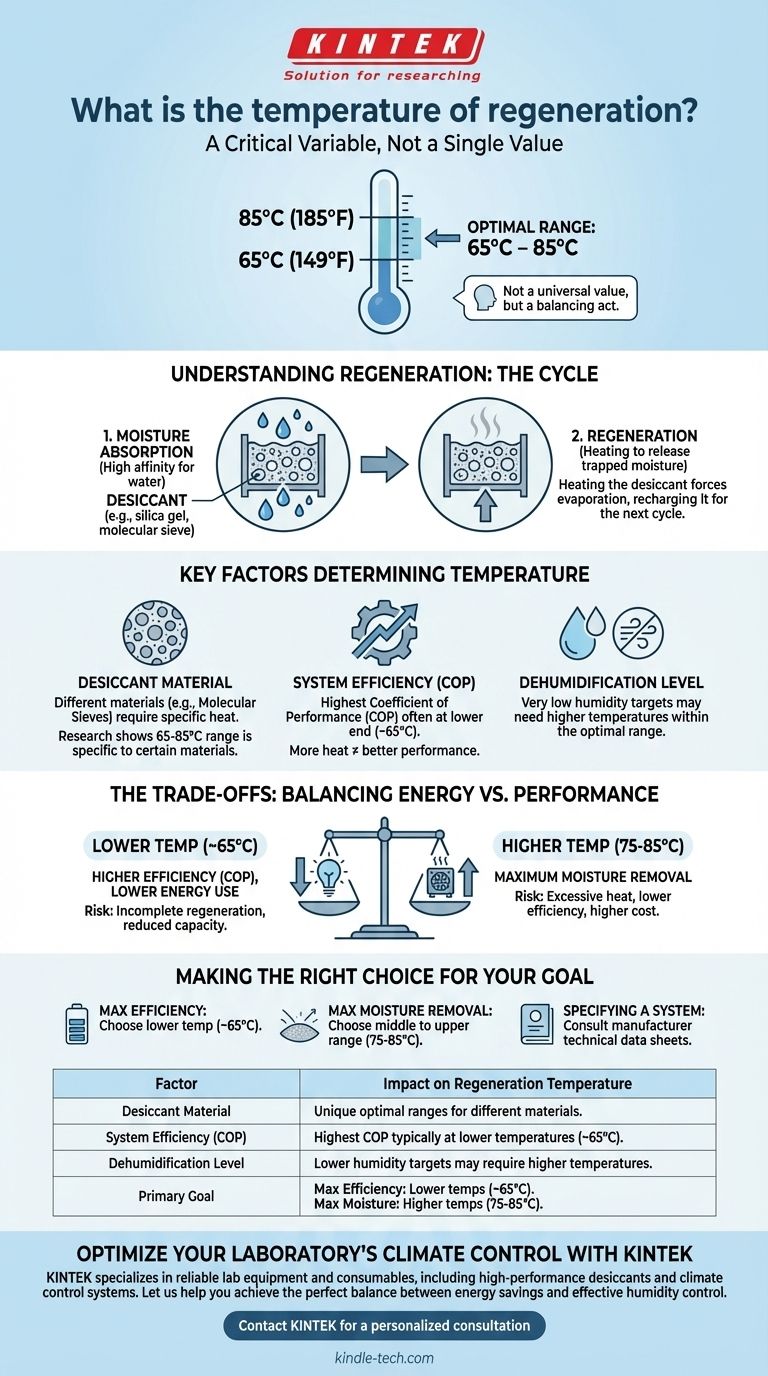

The optimal regeneration temperature is not a single value but rather a critical variable that depends heavily on the specific system and its goals. For common solid desiccant systems, research indicates an optimal range is typically between 65°C and 85°C (149°F to 185°F). Studies have shown that the highest system efficiency is often achieved at the lower end of this range, around 65°C.

The core challenge is not finding a universal temperature but understanding the trade-off. The ideal regeneration temperature is a balancing act between the energy required to heat the desiccant and the system's overall dehumidification performance.

What "Regeneration" Actually Means

To understand the temperature, we must first understand the process. Desiccant-based systems, such as advanced dehumidifiers and air conditioners, rely on a cycle of moisture absorption and release.

The Role of a Desiccant

A desiccant is a material with a high affinity for water vapor, effectively pulling moisture out of the air. Common examples include silica gel and molecular sieves. Think of it as a reusable, high-capacity sponge for humidity.

The Purpose of Regeneration

Once the desiccant becomes saturated with moisture, it can no longer perform its function. Regeneration is the process of heating the desiccant to force this trapped moisture to evaporate, effectively "drying out" or recharging the material so it can begin absorbing moisture again.

Key Factors That Determine the Temperature

There is no "one-size-fits-all" answer because the optimal temperature is influenced by several interconnected factors. The values cited in research represent an ideal range for specific conditions.

The Desiccant Material

Different materials have different properties. A molecular sieve, as mentioned in the research, has a highly porous structure that requires a specific amount of heat energy to release its trapped water molecules. The optimal range of 65–85°C is specific to this type of material under certain operating conditions.

System Efficiency (COP)

Coefficient of Performance (COP) is a critical metric that measures how efficiently a system operates. It's the ratio of useful cooling or dehumidification provided to the energy consumed. As research by Jurinak et al. (1984) showed, the highest COP was achieved at 65°C, even though the system was tested up to 105°C. This demonstrates that more heat does not always equal better performance.

Required Dehumidification Level

The amount of moisture you need to remove from the air also dictates the necessary temperature. To achieve very low humidity levels, the desiccant must be as "dry" as possible, which may require a regeneration temperature at the higher end of its optimal range.

Understanding the Trade-offs

Choosing a regeneration temperature is a strategic decision that directly impacts both cost and performance.

Energy Consumption vs. Performance

This is the central trade-off. Lower temperatures require less energy input, leading to a higher COP and lower operating costs. However, if the temperature is too low, performance may suffer.

The Risk of Incomplete Regeneration

Using a temperature that is too low for the conditions can result in the desiccant not releasing all of its moisture. This reduces its capacity to absorb water in the next cycle, degrading the system's overall effectiveness.

The Problem of Excessive Heat

Applying more heat than necessary is simply wasteful. It increases energy consumption (lowering the COP) without providing a proportional benefit in moisture removal. It's the point of diminishing returns.

Making the Right Choice for Your Goal

To select the appropriate temperature, you must first define your primary objective.

- If your primary focus is maximum energy efficiency (highest COP): Operate at the lower end of the recommended range for your specific desiccant, often around 65°C, as this minimizes energy input.

- If your primary focus is maximum moisture removal: You may need to use a temperature in the middle to upper end of the material's optimal range (e.g., 75-85°C), accepting a potential reduction in energy efficiency.

- If you are designing or specifying a system: Always consult the desiccant manufacturer's technical data sheets, as they provide the precise operating parameters for achieving optimal performance and longevity.

Ultimately, optimizing regeneration temperature is about balancing energy input with dehumidification output to meet your specific performance goals.

Summary Table:

| Factor | Impact on Regeneration Temperature |

|---|---|

| Desiccant Material | Different materials (e.g., silica gel, molecular sieves) have unique optimal temperature ranges. |

| System Efficiency (COP) | Highest efficiency (COP) is often achieved at lower temperatures (~65°C). |

| Dehumidification Level | Lower humidity targets may require higher temperatures within the optimal range. |

| Primary Goal | Max Efficiency: Use lower temps (~65°C). Max Moisture Removal: Use higher temps (75-85°C). |

Optimize Your Laboratory's Climate Control with KINTEK

Struggling to balance energy costs and dehumidification performance in your lab? The precise control of regeneration temperature is key to maximizing the efficiency and lifespan of your desiccant-based equipment.

KINTEK specializes in providing reliable lab equipment and consumables, including high-performance desiccants and climate control systems tailored to your specific laboratory needs. Our experts can help you select the right materials and configure your system for optimal performance.

Let us help you achieve the perfect balance between energy savings and effective humidity control.

Contact KINTEK today for a personalized consultation and ensure your lab environment is perfectly conditioned for your critical work.

Visual Guide

Related Products

- High Performance Laboratory Freeze Dryer

- High Performance Laboratory Freeze Dryer for Research and Development

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Graphite Vacuum Continuous Graphitization Furnace

- Infrared Heating Quantitative Flat Plate Press Mold

People Also Ask

- What is pyrolysis rate? Mastering Control for Optimal Bio-Char, Bio-Oil, and Syngas Production

- What are the problems of rotary kiln of cement and their remedies? Achieve Long-Term Reliability and Efficiency

- What is conventional pyrolysis? A Guide to Slow Pyrolysis for Biochar Production

- How expensive is it to run an electric kiln? Calculate Your True Firing Costs

- What is the temperature zone in a rotary kiln? Master the Thermal Profile for Optimal Processing

- What is calcination in short answer? A Guide to High-Temperature Material Transformation

- Does calcination produce CO2? Understanding the Role of Carbonates in Thermal Decomposition

- How does a rotary calciner work? Achieve Uniform Thermal Processing for Bulk Solids