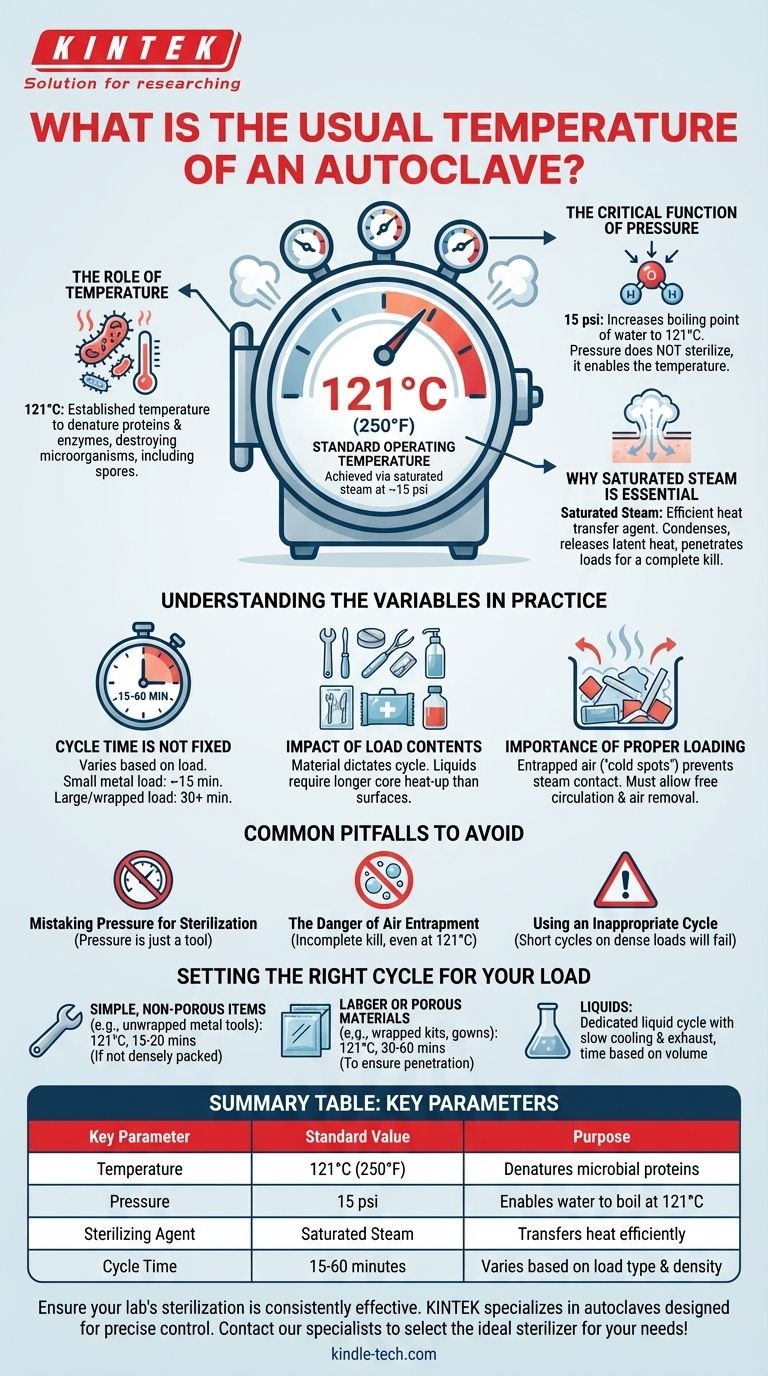

The standard operating temperature for most autoclaves is 121°C (250°F). This temperature is achieved by using saturated steam under a pressure of approximately 15 pounds per square inch (psi). While this temperature is the industry benchmark, the duration of the cycle can vary significantly, typically from 15 to 60 minutes.

Effective sterilization is not about a single temperature setting, but about the precise relationship between temperature, pressurized steam, and time. The 121°C standard is the foundation, but its success depends entirely on how it's applied to the specific materials being sterilized.

The Core Principle: How Steam Sterilizes

At its heart, an autoclave is a pressure chamber designed to kill all microbial life, including heat-resistant spores. This is accomplished through a combination of three critical factors working in perfect concert.

The Role of Temperature

The target of 121°C (250°F) is the established temperature required to denature the essential proteins and enzymes within microorganisms, leading to their rapid destruction. This temperature provides a reliable margin of safety for killing even the most resilient bacterial spores.

The Critical Function of Pressure

Under normal atmospheric conditions, water boils at 100°C (212°F). To reach the higher sterilization temperature of 121°C, the autoclave increases the pressure inside its chamber to about 15 psi above atmospheric pressure. It is the pressure that allows the water to boil at this higher temperature; the pressure itself does not sterilize.

Why Saturated Steam is Essential

The actual sterilization agent is saturated steam—steam holding the maximum amount of water vapor. This moist heat is far more effective at transferring thermal energy than dry air. The steam condenses on cooler items in the load, releasing its heat and thoroughly penetrating surfaces to ensure a complete kill.

Understanding the Variables in Practice

While 121°C is the constant, the time required to achieve sterility is highly variable. The "standard" times of 15-30 minutes are only starting points that must be adjusted based on the nature of the load.

Cycle Time is Not Fixed

A small load of unwrapped metal instruments might be sterilized in 15 minutes. However, a large, dense load of wrapped surgical kits may require 30 minutes or more to allow the steam to penetrate completely to the center of the pack.

The Impact of Load Contents

The type of material being sterilized dictates the cycle parameters. Liquids, for example, require much longer to reach the target temperature at their core than a metal instrument does on its surface.

The Importance of Proper Loading

Entrapped air is the enemy of sterilization. Air pockets create "cold spots" that steam cannot reach, leading to sterilization failure. Items must be loaded to allow for free circulation of steam and removal of air.

Common Pitfalls to Avoid

Achieving the correct temperature reading on the gauge does not guarantee sterilization. Understanding the potential points of failure is crucial for ensuring the process is effective every time.

Mistaking Pressure for Sterilization

A common misconception is that the pressure sterilizes the items. Remember, pressure is only the tool used to achieve the high-temperature steam that actually does the work.

The Danger of Air Entrapment

If air is not properly evacuated from the chamber and the load, the autoclave will not reach the correct temperature uniformly. Even if the temperature sensor reads 121°C, pockets of cooler air can leave items unsterilized.

Using an Inappropriate Cycle

Applying a short, 15-minute cycle designed for simple instruments to a load of textiles or liquids will result in failure. The core of these items will never reach the required temperature for the necessary duration.

Setting the Right Cycle for Your Load

Choosing the correct parameters requires a clear understanding of what you are sterilizing. Always consult your institution's specific protocols and the autoclave manufacturer's instructions.

- If your primary focus is simple, non-porous items (e.g., unwrapped metal tools): A standard cycle of 121°C for 15-20 minutes is often sufficient, assuming the load is not densely packed.

- If your primary focus is larger or porous materials (e.g., wrapped kits, gowns): The cycle time at 121°C must be extended, often to 30-60 minutes, to ensure full steam penetration.

- If your primary focus is liquids: You must use a dedicated liquid cycle with a slower cooling and exhaust phase, with time determined by the volume in each container.

Ultimately, mastering autoclaving means seeing beyond a single temperature and understanding the dynamic interplay between heat, steam, and the load itself.

Summary Table:

| Key Parameter | Standard Value | Purpose |

|---|---|---|

| Temperature | 121°C (250°F) | Denatures microbial proteins |

| Pressure | 15 psi | Enables water to boil at 121°C |

| Sterilizing Agent | Saturated Steam | Transfers heat efficiently |

| Cycle Time | 15-60 minutes | Varies based on load type and density |

Ensure your lab's sterilization is consistently effective. The right autoclave is critical for reliable results. KINTEK specializes in laboratory equipment and consumables, providing autoclaves designed for precise temperature control and steam penetration. Let our experts help you select the ideal sterilizer for your specific materials and protocols.

Contact our sterilization specialists today to discuss your laboratory's needs!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What is the primary function of a laboratory autoclave in the pre-treatment of medical plastic waste for liquid fuel?

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing