In short, vacuum evaporation is a process where a material is heated in a high-vacuum chamber until it turns into a vapor. This vapor then travels unimpeded and condenses onto a cooler surface, forming an extremely thin and pure coating or, in a different application, separating a liquid from its contaminants. It is a foundational technique in a family of processes known as Physical Vapor Deposition (PVD).

The critical insight is that the vacuum is not just a container; it is an active part of the process. By removing air and other particles, the vacuum ensures the evaporated material travels in a straight line, resulting in a highly pure and uniform deposit on the target substrate without reacting with any contaminants.

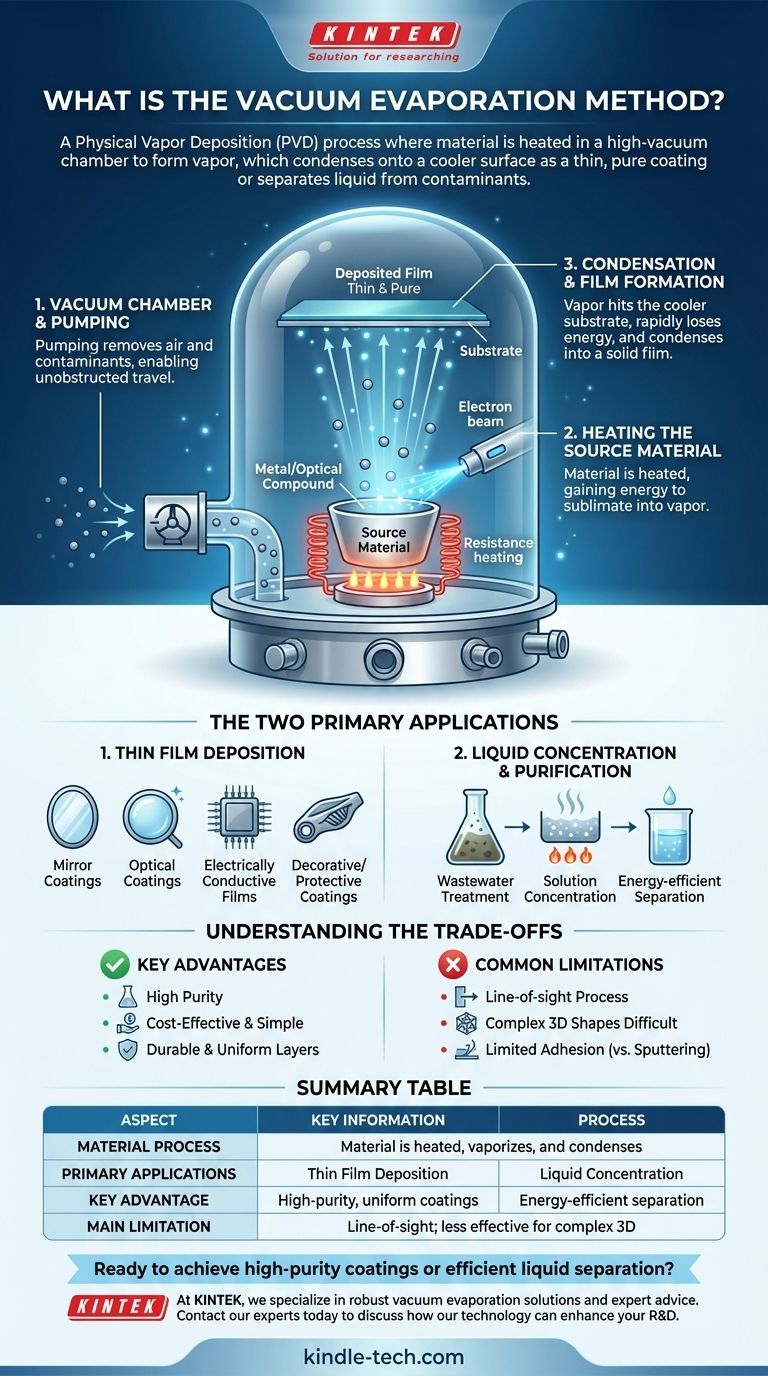

How the Vacuum Evaporation Process Works

Vacuum evaporation is a straightforward, line-of-sight process that relies on a phase change from solid or liquid to gas and back again. The entire operation takes place inside a sealed vacuum chamber.

The Critical Role of the Vacuum

The process begins by pumping nearly all the air out of a chamber. This high-vacuum environment is essential for two reasons.

First, it prevents contamination. With no air molecules (like oxygen or nitrogen) present, the vaporized material cannot react with them on its way to the target.

Second, it allows for unobstructed travel. The vaporized atoms or molecules can move directly from the source to the substrate without colliding with other particles, ensuring a clean and direct deposition path.

Heating the Source Material

A source material, such as a metal or an optical compound, is placed inside the chamber. This material is then heated using methods like resistance heating or an electron beam.

As the material heats up, its atoms gain enough energy to overcome their internal binding forces. This causes the material to sublimate or evaporate directly into a gaseous state, or vapor.

Condensation and Film Formation

This vapor travels through the vacuum and comes into contact with a cooler surface, known as the substrate. This is the object being coated.

Upon hitting the cooler substrate, the vapor rapidly loses its energy and condenses back into a solid state. This process builds up atom by atom, creating a thin, uniform, and highly pure film.

The Two Primary Applications of Vacuum Evaporation

While the underlying physics is the same, the goal of vacuum evaporation splits into two distinct application domains: creating solid coatings and concentrating liquid solutions.

1. Thin Film Deposition

This is the most common use of vacuum evaporation. The goal is to apply a functional or decorative layer onto a surface.

Applications include creating mirror coatings, anti-reflective optical coatings for lenses, electrically conductive films for electronics, and protective or decorative coatings on everything from automotive parts to jewelry. When used with metals, this is often called vacuum metallization.

2. Liquid Concentration and Purification

In this application, a liquid solution (like industrial wastewater) is heated under a vacuum. Lowering the pressure also lowers the liquid's boiling point, reducing the energy needed for evaporation.

The water evaporates into a vapor, leaving behind contaminants that have higher boiling points. This vapor is then collected and condensed back into purified water, effectively separating it from the dissolved substances.

Understanding the Trade-offs

Like any technical process, vacuum evaporation has clear strengths and weaknesses that make it suitable for some tasks but not others.

Key Advantages

The process is valued for its relative simplicity and cost-effectiveness compared to more complex PVD methods.

It produces films of very high purity because the vacuum environment minimizes contamination. The resulting layers are known for their durability, long service life, and high dimensional accuracy.

Common Limitations

Vacuum evaporation is a line-of-sight process. The vapor travels in a straight line, which can make it difficult to uniformly coat complex, three-dimensional shapes with undercuts or hidden surfaces.

Additionally, the adhesion of the deposited film to the substrate can sometimes be weaker than films produced by higher-energy processes like sputtering. The choice of materials that can be easily evaporated is also more limited compared to other techniques.

How to Apply This to Your Goal

Choosing a deposition or separation technique depends entirely on your specific requirements for material, substrate shape, and final properties.

- If your primary focus is creating a high-purity optical or metallic coating on a relatively simple surface: Vacuum evaporation is an excellent, reliable, and cost-effective choice.

- If your primary focus is coating a complex 3D object with high adhesion: You may need to explore other PVD methods like sputtering, which offers better coverage on intricate geometries.

- If your primary focus is efficiently separating water from contaminants with high boiling points: Vacuum evaporation is a proven and energy-efficient method for wastewater treatment and solution concentration.

Ultimately, understanding vacuum evaporation is about recognizing the power of an empty space to enable a perfect transfer of material.

Summary Table:

| Aspect | Key Information |

|---|---|

| Process | Material is heated in a vacuum, vaporizes, and condenses on a cooler substrate. |

| Primary Applications | Thin Film Deposition (e.g., optics, electronics), Liquid Concentration/Purification. |

| Key Advantage | High-purity, uniform coatings; Energy-efficient liquid separation. |

| Main Limitation | Line-of-sight process; less effective for complex 3D shapes. |

Ready to achieve high-purity coatings or efficient liquid separation?

At KINTEK, we specialize in providing robust vacuum evaporation solutions and expert advice for your laboratory's specific challenges. Whether you're developing advanced optical coatings, electronic components, or need to purify solutions, our equipment and consumables are designed for precision and reliability.

Contact our experts today to discuss how our vacuum evaporation technology can enhance your research and development process.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems