In manufacturing, titanium is used for high-performance applications where its exceptional strength-to-weight ratio, superior corrosion resistance, and biocompatibility are critical. It is a premium material of choice in industries like aerospace, medical, chemical processing, and high-end consumer goods where performance requirements justify its higher cost.

The decision to use titanium is almost always a strategic trade-off. It is chosen when the operational demands for lightweight strength and extreme durability are so high that conventional materials like steel or aluminum would fail or impose an unacceptable weight penalty.

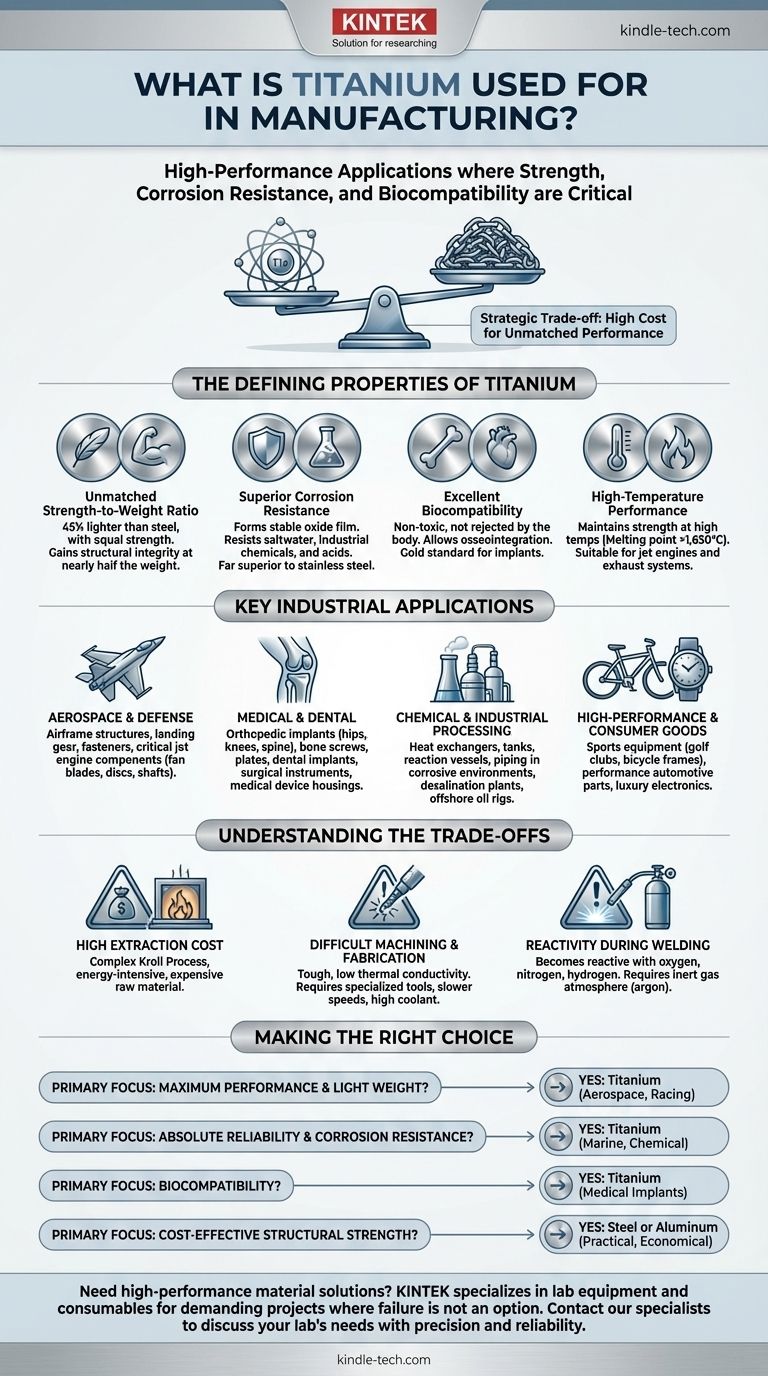

The Defining Properties of Titanium

To understand where titanium is used, we must first understand its core characteristics. Its unique combination of properties is what makes it indispensable for certain demanding roles.

Unmatched Strength-to-Weight Ratio

Titanium alloys are as strong as many common steels but are approximately 45% lighter. This is the single most important property driving its use in aerospace and high-performance vehicles.

Think of it as gaining the structural integrity of steel at nearly half the weight, a benefit that directly translates to fuel efficiency and increased payload capacity.

Superior Corrosion Resistance

Titanium naturally forms a stable, highly adherent, and protective oxide film on its surface. This film makes it exceptionally resistant to corrosion from salt water, industrial chemicals, and various acids.

This property makes it far superior to most stainless steels in harsh marine or chemical environments, where longevity and reliability are paramount.

Excellent Biocompatibility

Titanium is non-toxic and is not rejected by the human body. Its surface allows bone to grow and adhere to it, a process known as osseointegration.

This makes it the gold standard for medical implants, such as hip and knee replacements, dental implants, and pacemakers, where long-term integration with the body is essential.

High-Temperature Performance

Titanium alloys maintain their strength at significantly higher temperatures than aluminum and magnesium alloys. With a melting point of over 1,650°C (3,000°F), it is suitable for components exposed to moderate to high heat.

This is crucial for parts like jet engine components and high-performance automotive exhaust systems.

Key Industrial Applications

The properties above dictate exactly where titanium provides the most value. Its applications are specialized and focus on environments where other metals would be compromised.

Aerospace and Defense

This is the largest market for titanium. It's used for critical airframe structures, landing gear, fasteners, and vital jet engine components like fan blades, discs, and shafts where temperature and stress are extreme.

Medical and Dental

Due to its biocompatibility, titanium is the primary material for orthopedic implants (hips, knees, spine), bone screws and plates, dental implants, and housings for medical devices. Surgical instruments are also often made from titanium for their lightness and ability to withstand sterilization.

Chemical and Industrial Processing

In environments with highly corrosive chemicals, titanium is used for heat exchangers, tanks, reaction vessels, and piping. Its ability to resist attack from chlorides makes it essential in desalination plants and offshore oil rigs.

High-Performance and Consumer Goods

You find titanium where performance and a premium feel are desired. This includes high-end sports equipment (golf club heads, bicycle frames), performance automotive parts (valves, connecting rods, exhaust systems), and luxury consumer electronics like watches and laptop casings.

Understanding the Trade-offs

Choosing titanium is not without its significant challenges and costs. These factors limit its use to only the most necessary applications.

The High Cost of Extraction

Titanium is not rare, but the process to extract it from its ore (the Kroll Process) is complex, energy-intensive, and expensive. This results in a raw material cost many times higher than that of steel or aluminum.

Difficult Machining and Fabrication

Titanium's toughness and low thermal conductivity make it notoriously difficult to machine. It requires lower cutting speeds, specialized tools, and high amounts of coolant. This significantly increases manufacturing time and cost.

Reactivity During Welding

While stable at room temperature, titanium becomes highly reactive with oxygen, nitrogen, and hydrogen at the elevated temperatures required for welding. This necessitates welding in an inert gas atmosphere (like argon) to prevent contamination and embrittlement of the weld.

Making the Right Choice for Your Project

The decision to use titanium is driven entirely by the operational demands of the final product.

- If your primary focus is maximum performance where weight is critical: Titanium is the superior choice for applications like aerospace components or competitive racing parts.

- If your primary focus is absolute reliability in a corrosive environment: Titanium offers unparalleled longevity for marine hardware or chemical processing equipment.

- If your primary focus is biocompatibility for direct human contact: Titanium is the proven and trusted standard for medical and dental implants.

- If your primary focus is cost-effective structural strength: Steel or aluminum will almost always be the more practical and economical solution.

Ultimately, titanium is an engineering tool for solving problems where performance cannot be compromised.

Summary Table:

| Property | Key Benefit | Primary Manufacturing Applications |

|---|---|---|

| Strength-to-Weight Ratio | High strength at 45% lighter than steel | Aerospace structures, performance automotive parts, sports equipment |

| Corrosion Resistance | Excellent resistance to salt water and chemicals | Chemical processing equipment, marine hardware, desalination plants |

| Biocompatibility | Non-toxic, integrates with human bone | Medical implants (hips, knees), dental implants, surgical instruments |

| High-Temperature Performance | Maintains strength at elevated temperatures | Jet engine components, exhaust systems |

Need a high-performance material solution for your lab or manufacturing process? The unique properties of titanium make it ideal for applications where failure is not an option. At KINTEK, we specialize in providing high-quality lab equipment and consumables to support your most demanding projects. Whether you're developing new materials or require reliable components, our expertise can help you achieve superior results. Contact our specialists today to discuss how we can support your laboratory's specific needs with precision and reliability.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Single Horizontal Jar Mill

- Laboratory Test Sieves and Sieving Machines

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What equipment is needed for pyrolysis? The 4 Core Components for a Successful Plant

- What are the most common types of heat treatment? Master Annealing, Hardening, Tempering & More

- What are the safety considerations for heat treating metal? Protect Your Team from Extreme Heat & Hazards

- What role does a constant temperature forced-air drying oven play in loading metal oxides? Ensure Catalyst Stability

- How plastic can be used as fuel? Turn Waste into Energy with Pyrolysis & Photo-Reforming

- What is used in sintering process? Powder, Pressure, and Heat to Create Durable Parts

- What is isostatic pressing hot and cold? Forming vs. Finishing for Superior Materials

- What is sintering in electronics? A Key Process for High-Performance Components