In short, you should only autoclave lab supplies that are explicitly rated to withstand high-pressure steam, which primarily includes specific glassware, stainless steel instruments, certain plastics like polypropylene, and aqueous solutions. The core purpose is either to sterilize clean items for future use or to decontaminate biohazardous waste before disposal. Items that are flammable, corrosive, reactive, radioactive, or made of incompatible plastics like polystyrene must never be autoclaved.

The central decision is not based on a simple list, but on a principle of material compatibility and purpose. Autoclaving is the benchmark for sterilization, but applying it to the wrong material can lead to equipment damage, failed sterilization, or a serious safety hazard.

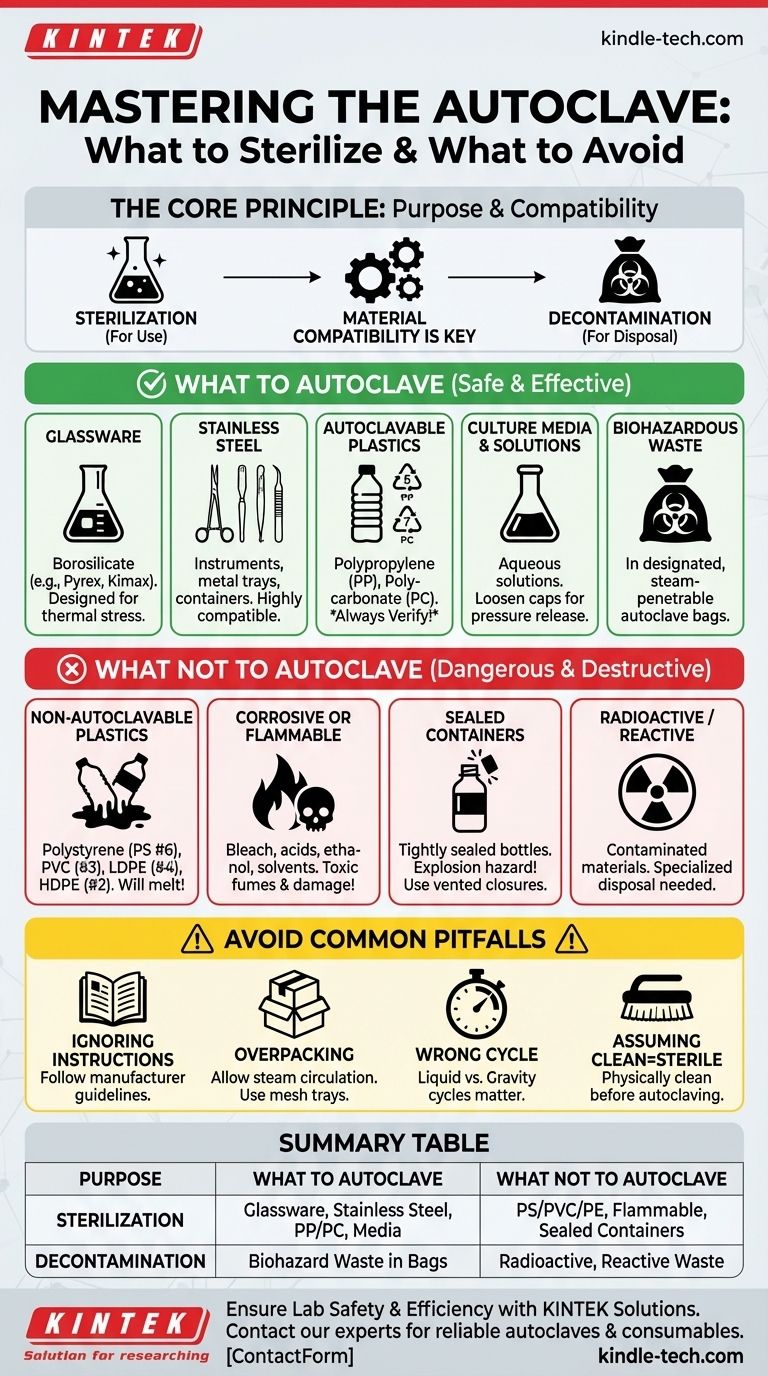

The Purpose: Sterilization vs. Decontamination

Understanding why you are autoclaving is the first step in deciding what can be autoclaved. The process serves two distinct but related functions.

Achieving Sterility for Use

This is the process of eliminating all forms of microbial life, including spores, from an object that will be used in a sterile procedure.

The goal here is to prevent contamination of your experiment. This applies to items like microbiological media, surgical tools, and glassware that will hold sterile cultures.

Ensuring Safe Decontamination

This is the process of treating biohazardous materials to render them non-infectious before they are discarded as regular waste.

Here, the goal is public and occupational safety. This applies to used petri dishes, spent liquid cultures, and other materials that have come into contact with microorganisms.

A Framework for What to Autoclave

Instead of a simple list, it's more effective to categorize items by material. Always check for a manufacturer's symbol or statement confirming an item is "autoclavable."

Items Routinely Autoclaved

- Glassware: Borosilicate glass (Pyrex, Kimax) is designed to handle the thermal stress of autoclaving. Lesser-quality soda-lime glass can crack.

- Stainless Steel: Surgical instruments, metal trays, and containers are highly compatible and easily sterilized.

- Autoclavable Plastics: The most common is polypropylene (PP, #5). Polycarbonate (PC, #7) is also often autoclavable. Always verify, as some plastics will melt and ruin the autoclave chamber.

- Culture Media and Solutions: Aqueous solutions are routinely sterilized. Caps must be loosened to prevent pressure buildup.

- Biohazardous Waste: This includes cultures, stocks, and contaminated lab waste. It must be placed in a designated, steam-penetrable autoclave bag.

Critical Exclusions: What NOT to Autoclave

Placing the wrong item in an autoclave is a common and dangerous mistake. The following materials should never be autoclaved.

Non-Autoclavable Plastics

Most consumer plastics will melt. This includes polystyrene (PS, #6), polyvinyl chloride (PVC, #3), and both low- and high-density polyethylene (LDPE, #4 and HDPE, #2). Melting plastic creates a disastrous mess and can damage the equipment.

Corrosive or Flammable Chemicals

Never autoclave bleach, acids, bases, or organic solvents (e.g., ethanol, methanol, chloroform). The high heat will vaporize these chemicals, releasing toxic, corrosive, or flammable fumes that can damage the autoclave and pose a severe risk to personnel.

Items with Sealed Air Pockets

Any container that is tightly sealed, such as a bottle with its cap screwed on completely, can explode under the extreme pressure changes inside the autoclave. Always loosen caps significantly (a quarter-turn is not enough) or use vented closures.

Radioactive or Chemically Reactive Materials

Items contaminated with radioactive materials or certain reactive chemicals require specialized disposal procedures and must not be autoclaved.

Understanding the Common Pitfalls

Successful autoclaving goes beyond just choosing the right item. Procedural errors can lead to failed sterilization or safety incidents.

Ignoring Manufacturer's Instructions

The reference on an item being "autoclavable" from the manufacturer is the ultimate authority. This supersedes any general list. Always follow their specific instructions for cycle time and temperature.

Improper Loading and Overpacking

Steam must circulate freely to sterilize all surfaces. Overpacking a chamber or placing items in solid-bottomed pans prevents steam penetration, leading to incomplete sterilization. Always use perforated or mesh-bottom trays.

Choosing the Incorrect Cycle

Autoclaves have different cycles for different loads.

- Liquid Cycles use a slow exhaust to prevent liquids from boiling over.

- Gravity (or Dry) Cycles use a fast exhaust for glassware and wrapped instruments.

Using a gravity cycle for liquids will cause them to boil violently out of their containers, making a mess and rendering the sterilization useless.

Assuming "Clean" is "Sterile"

Autoclaving is a sterilization process, not a cleaning one. Items, especially instruments, should be physically cleaned of all debris before being placed in the autoclave. Any residual organic matter can shield microbes from the steam.

Making the Right Choice in Your Lab

Your decision should be guided by your specific objective. Always prioritize safety and efficacy.

- If your primary focus is preparing sterile equipment for use: Ensure the items are made of compatible materials (Pyrex, stainless steel, polypropylene) and are physically clean before selecting the correct cycle for the load.

- If your primary focus is decontaminating biohazardous waste: Use a validated autoclave bag, add a small amount of water (250-500 mL) to the bag to ensure steam generation, and never seal the bag completely shut before autoclaving.

- If you are ever unsure about an item: Do not autoclave it. The risk of damaging equipment or creating a safety hazard is too high. Always find the manufacturer's documentation or use an alternative method.

Properly identifying what can and cannot be autoclaved is a foundational skill for maintaining a safe and effective laboratory environment.

Summary Table:

| Purpose | What to Autoclave | What NOT to Autoclave |

|---|---|---|

| Sterilization for Use | Glassware (Borosilicate), Stainless Steel Instruments, Autoclavable Plastics (PP, PC), Culture Media | Non-autoclavable Plastics (PS, PVC, PE), Flammable/Corrosive Chemicals, Sealed Containers |

| Decontamination for Disposal | Biohazardous Waste in Steam-Penetrable Bags | Radioactive Materials, Chemically Reactive Waste |

Ensure your lab's safety and efficiency with the right equipment.

Autoclaving is a critical process, but it requires compatible supplies and reliable equipment to be effective. At KINTEK, we specialize in providing high-quality lab equipment and consumables designed for rigorous sterilization protocols. Our autoclaves and compatible supplies are built to deliver consistent, safe performance, protecting your experiments and your team.

Whether you need to sterilize instruments for use or decontaminate biohazardous waste, KINTEK has the solutions to meet your laboratory's specific needs.

Contact our experts today to discuss how we can support your lab's sterilization and safety requirements.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What precautions should be taken during autoclave in laboratory? A Complete Safety Guide to Prevent Burns and Explosions

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- How does an autoclave sterilize instruments supplies and equipment? A Guide to High-Pressure Steam Sterilization