The most common products made by blown film extrusion are flexible plastic films used for bags, liners, and wraps. This process is the industrial backbone for producing everything from grocery bags and food packaging to heavy-duty construction sheeting and agricultural films. It is dominant in any industry that requires thin, continuous, and seamless plastic sheeting.

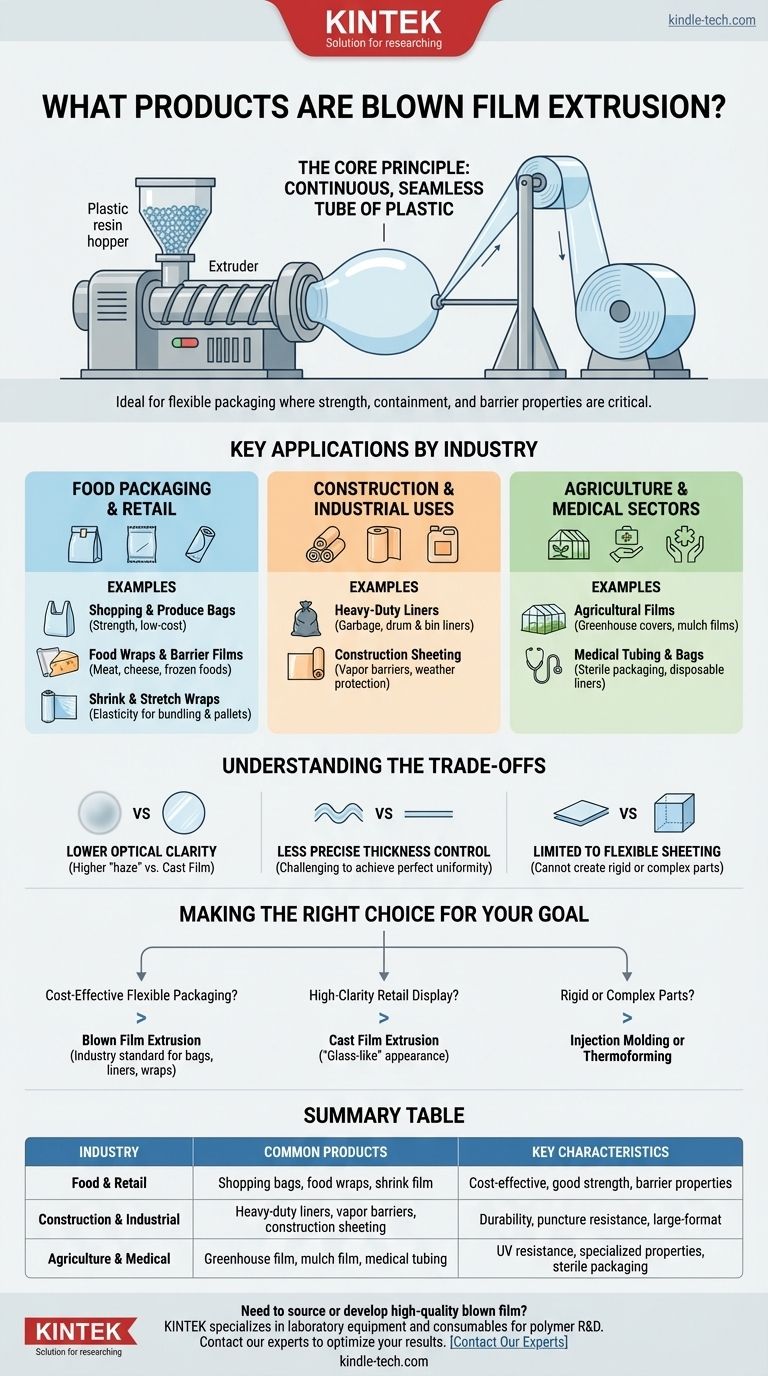

The core principle of blown film extrusion is its ability to create a continuous, seamless tube of plastic. This fundamental characteristic makes it the ideal and most cost-effective method for producing flexible packaging where strength, containment, and barrier properties are critical.

Key Applications by Industry

Blown film extrusion's versatility allows it to serve a diverse set of industries, each leveraging the unique properties of the film produced. The final product is determined by the type of plastic resin used, the dimensions of the extrusion die, and any post-extrusion processing.

Food Packaging and Retail

This is the largest and most visible market for blown film products. The focus here is on protection, preservation, and presentation.

Shopping and Produce Bags The ubiquitous T-shirt bag is a classic example. The process allows for the high-speed, low-cost production of lightweight bags with surprising strength.

Food Wraps and Barrier Films Films used for packaging meat, cheese, and frozen foods often involve multiple layers (co-extrusion) to create barriers against oxygen and moisture, extending shelf life.

Shrink and Stretch Wraps This film is engineered for elasticity. It is used to bundle consumer goods (like multi-packs of water bottles) or to secure pallets for shipping, providing load stability and protection.

Construction and Industrial Uses

In industrial settings, the emphasis shifts from aesthetics to durability, strength, and large-format coverage.

Heavy-Duty Liners Garbage bags, drum liners, and bin liners rely on the seamless tube structure of blown film to prevent leaks. The film's puncture resistance is a key performance metric.

Construction Sheeting Large rolls of plastic film are used as vapor barriers, weather protection on job sites, or as temporary enclosures. The process can create very wide sheeting to cover large areas efficiently.

Agriculture and Medical Sectors

These specialized applications leverage specific film properties like UV resistance, durability, or sterility.

Agricultural Films Products like greenhouse covers, mulch films, and silage bags are designed to withstand environmental exposure. Additives can be mixed into the resin to provide UV protection or specific light-filtering properties.

Medical Tubing and Bags The seamless nature of the process is critical for producing sterile packaging, such as bags for medical devices or disposable liners. It ensures integrity and prevents contamination.

Understanding the Trade-offs

While incredibly versatile, blown film extrusion is not the optimal choice for every application. Understanding its limitations is key to making informed decisions.

Lower Optical Clarity

Compared to its alternative, cast film extrusion, blown film typically has lower clarity and a higher "haze" level. The cooling process causes slight imperfections in the crystal structure of the plastic, making it less transparent.

Less Precise Thickness Control

The nature of blowing a bubble of plastic makes achieving perfectly uniform thickness (or "gauge") more challenging than with cast film, where the plastic is laid onto a chilled roller. This can be a critical factor in high-performance applications.

Limited to Flexible Sheeting

Blown film extrusion is exclusively for producing thin, flexible films. It cannot create rigid sheets, containers, or complex three-dimensional parts. Those products require entirely different processes like injection molding or thermoforming.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on the requirements of your final product.

- If your primary focus is cost-effective flexible packaging: Blown film extrusion is the industry standard for bags, liners, and general-purpose wraps where strength and value are paramount.

- If your primary focus is high-clarity retail display: Consider cast film extrusion, as its superior optical properties provide a "glass-like" appearance crucial for premium on-the-shelf appeal.

- If your primary focus is creating rigid or complex parts: You must look to other processes like injection molding for solid components or thermoforming for thin-walled containers.

Ultimately, recognizing that blown film extrusion excels at producing strong, seamless plastic tubes is the key to understanding its role in creating the countless flexible products we use every day.

Summary Table:

| Industry | Common Blown Film Products | Key Characteristics |

|---|---|---|

| Food & Retail | Shopping bags, food wraps, shrink film | Cost-effective, good strength, barrier properties |

| Construction & Industrial | Heavy-duty liners, vapor barriers, construction sheeting | Durability, puncture resistance, large-format |

| Agriculture & Medical | Greenhouse film, mulch film, medical tubing | UV resistance, specialized properties, sterile packaging |

Need to source or develop high-quality blown film for your application? KINTEK specializes in providing laboratory equipment and consumables essential for polymer research and development. Whether you are testing new resin formulations, optimizing film properties, or ensuring quality control, our solutions can help you achieve superior results. Contact our experts today to discuss how we can support your laboratory and production goals.

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What is the milling process of rubber? Transform Raw Rubber into a Workable Compound

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- What is the process of making rubber sheets? From Raw Rubber to Engineered Performance

- How do you recycle rubber waste? Unlock the 3 Key Methods for Tire & Rubber Recycling

- What are natural rubber sheets used for? Unlock Durability, Elasticity, and Vibration Damping

- What to do with injection molding? Mass-Produce High-Quality Plastic Parts Efficiently

- What is a rubber mixing mill used for? Transforming Raw Rubber into High-Performance Compounds

- What is an electric mixer called? Hand Mixer vs. Stand Mixer Explained