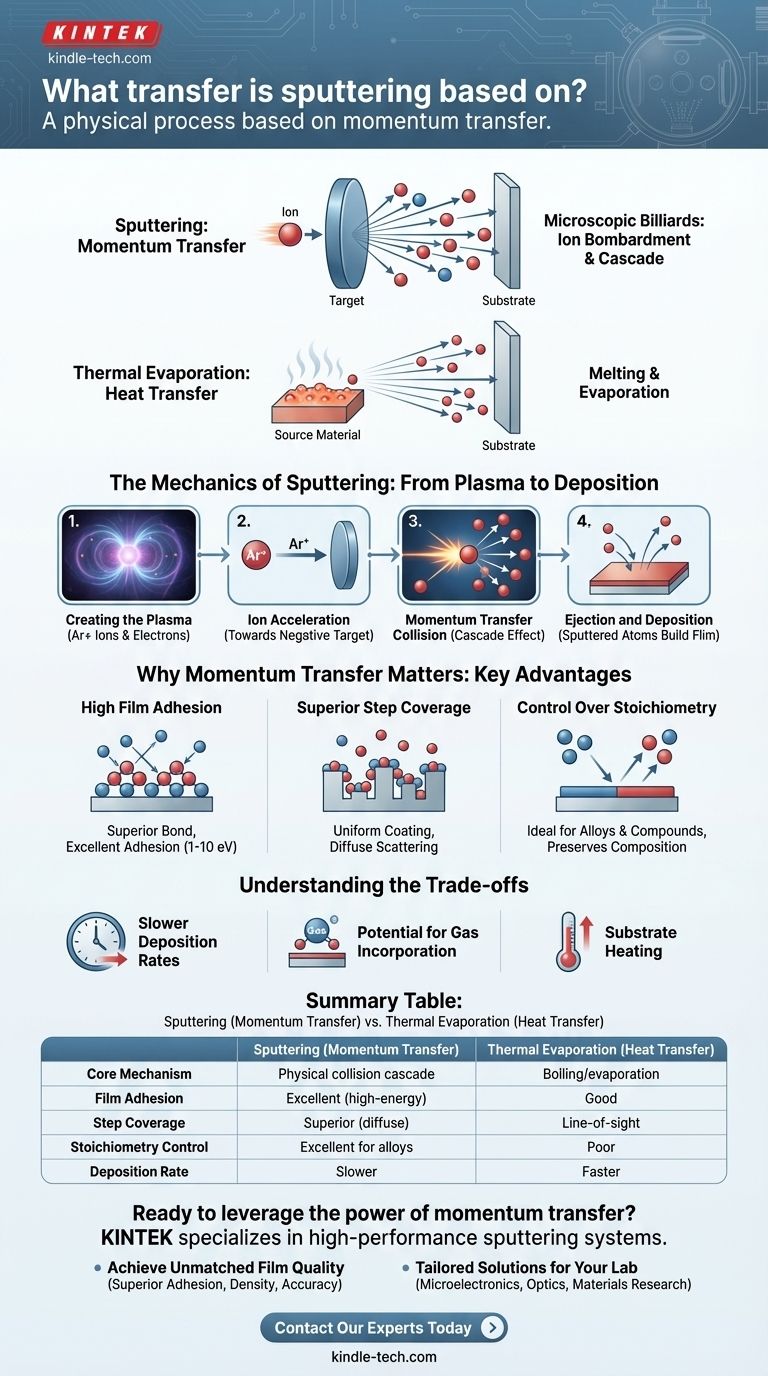

At its core, sputtering is a physical process based on momentum transfer. Unlike thermal evaporation, which boils material off a source, sputtering acts like a microscopic game of billiards. High-energy ions are accelerated into a solid material (the "target"), and the sheer force of this impact is enough to knock atoms loose from the target's surface, which then deposit onto a substrate as a thin film.

The critical takeaway is that sputtering is not a thermal or chemical process; it is a purely mechanical phenomenon at the atomic scale. An energetic ion transfers its momentum to target atoms through a collision cascade, physically ejecting them without melting or evaporating the source material.

The Mechanics of Sputtering: From Plasma to Deposition

To understand why momentum transfer is so fundamental, we must break down the sputtering process into its core stages, which all take place within a vacuum chamber.

Step 1: Creating the Plasma

The process begins by introducing a small amount of an inert gas, most commonly Argon (Ar), into the vacuum chamber.

A strong electric field is then applied. This field energizes the chamber, stripping electrons from the Argon atoms and creating a plasma—a glowing, ionized gas consisting of positive Argon ions (Ar+) and free electrons.

Step 2: Ion Acceleration

The material to be deposited, known as the target, is set up as a cathode, meaning it's given a large negative electrical charge.

The positively charged Argon ions in the plasma are strongly attracted to this negative target. They accelerate across the plasma, gaining significant kinetic energy on their journey.

Step 3: The Momentum Transfer Collision

This is the central event in sputtering. The high-energy Argon ion, acting like a cue ball, smashes into the surface of the target.

It does not melt a small spot. Instead, it triggers a collision cascade. The ion transfers its momentum to the atoms it hits, which in turn hit other atoms deeper in the material, transferring momentum down the line.

Step 4: Ejection and Deposition

If an atom near the target's surface receives enough momentum from this cascade to overcome the forces binding it to the material, it is ejected into the vacuum. This ejected atom is what we call "sputtered."

These sputtered atoms travel through the chamber and land on a nearby substrate (such as a silicon wafer or piece of glass), gradually building up a uniform, thin film.

Why Momentum Transfer Matters

The fact that sputtering is driven by physical collisions rather than heat gives it several distinct and powerful advantages over other deposition techniques.

High Film Adhesion

Sputtered atoms are ejected with significantly more kinetic energy (typically 1-10 eV) than thermally evaporated atoms (less than 1 eV).

When these energetic atoms strike the substrate, they can physically implant themselves into the top atomic layer. This creates a superior bond and results in films with excellent adhesion.

Superior Step Coverage

The collision cascade ejects target atoms in a wide, diffuse pattern, not in a straight line.

This scattering effect allows sputtered material to coat the sides and bottoms of microscopic features on a substrate's surface, a property known as step coverage, which is critical in microelectronics fabrication.

Control Over Stoichiometry

Because sputtering physically chisels atoms away, it removes them in the same ratio as they exist in the target.

This makes it an ideal method for depositing films of alloys or complex compounds (like oxides or nitrides) while preserving their original chemical composition, or stoichiometry. Thermal methods often fail here if one element evaporates more easily than another.

Understanding the Trade-offs

No technique is perfect. The reliance on momentum transfer introduces specific limitations that are important to recognize.

Slower Deposition Rates

The process of ejecting atoms one by one via ion bombardment is inherently less efficient than boiling them off in massive quantities. Consequently, sputtering deposition rates are typically much lower than those achieved with thermal evaporation.

Potential for Gas Incorporation

Some of the high-energy Argon ions used for bombardment can become embedded in the growing film. This gas incorporation can introduce stress and impurities, altering the film's electrical or optical properties.

Substrate Heating

While sputtering is not a "hot" process at the source, the substrate is constantly bombarded by energetic particles. This energy transfer can raise the substrate's temperature significantly, which can be detrimental to heat-sensitive materials like polymers.

Making the Right Choice for Your Goal

Selecting a deposition method requires aligning the process capabilities with your primary objective for the thin film.

- If your primary focus is high film adhesion, density, and durability: Sputtering is the superior choice due to the energetic nature of the momentum transfer process.

- If your primary focus is depositing complex alloys or compounds with precise composition: Sputtering's ability to preserve stoichiometry makes it highly reliable.

- If your primary focus is high-speed, low-cost deposition of simple elemental films: Thermal evaporation is often the faster and more economical solution.

Understanding that sputtering is driven by momentum transfer is the key to leveraging its unique advantages for creating robust, high-quality thin films.

Summary Table:

| Aspect | Sputtering (Momentum Transfer) | Thermal Evaporation (Heat Transfer) |

|---|---|---|

| Core Mechanism | Physical collision cascade | Boiling/evaporation of material |

| Film Adhesion | Excellent (high-energy atoms) | Good |

| Step Coverage | Superior (diffuse scattering) | Line-of-sight (poorer coverage) |

| Stoichiometry Control | Excellent for alloys/compounds | Poor (can separate elements) |

| Deposition Rate | Slower | Faster |

| Substrate Heating | Can be significant (particle bombardment) | Lower (if source is shielded) |

Ready to leverage the power of momentum transfer for your thin film applications?

Understanding the physics is the first step; implementing it is the next. KINTEK specializes in high-performance sputtering systems and lab equipment designed to deliver the unique advantages of this process:

- Achieve Unmatched Film Quality: Our sputtering systems are engineered to maximize the benefits of momentum transfer, ensuring superior film adhesion, density, and stoichiometric accuracy for alloys, oxides, and nitrides.

- Tailored Solutions for Your Lab: Whether you're in microelectronics, optics, or materials research, we provide the right equipment and consumables to meet your specific deposition goals.

Let's build better thin films together. Contact our experts today to discuss how a KINTEK sputtering solution can advance your research and production.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the role of a laboratory constant temperature drying oven in anaerobic digestion? Precision TS Analysis

- What is the source of XRF radiation? Understanding X-ray Tubes vs. Radioisotopes for Analysis

- How thick should coating be? Achieve the Perfect Balance for Performance and Cost

- What does CIP stand for Crip? Understanding the Meaning of Crip In Peace

- How does the sputtering technique allow for the coating of heat-sensitive materials? Efficient Cold Deposition Guide

- Is pyrolysis good or bad? A Balanced Look at the Waste-to-Energy Solution

- What are the safety precautions during heat treatment? A Guide to Managing Extreme Heat, Gases & Hazards

- What are the surface protection techniques? Enhance Durability and Performance for Your Components