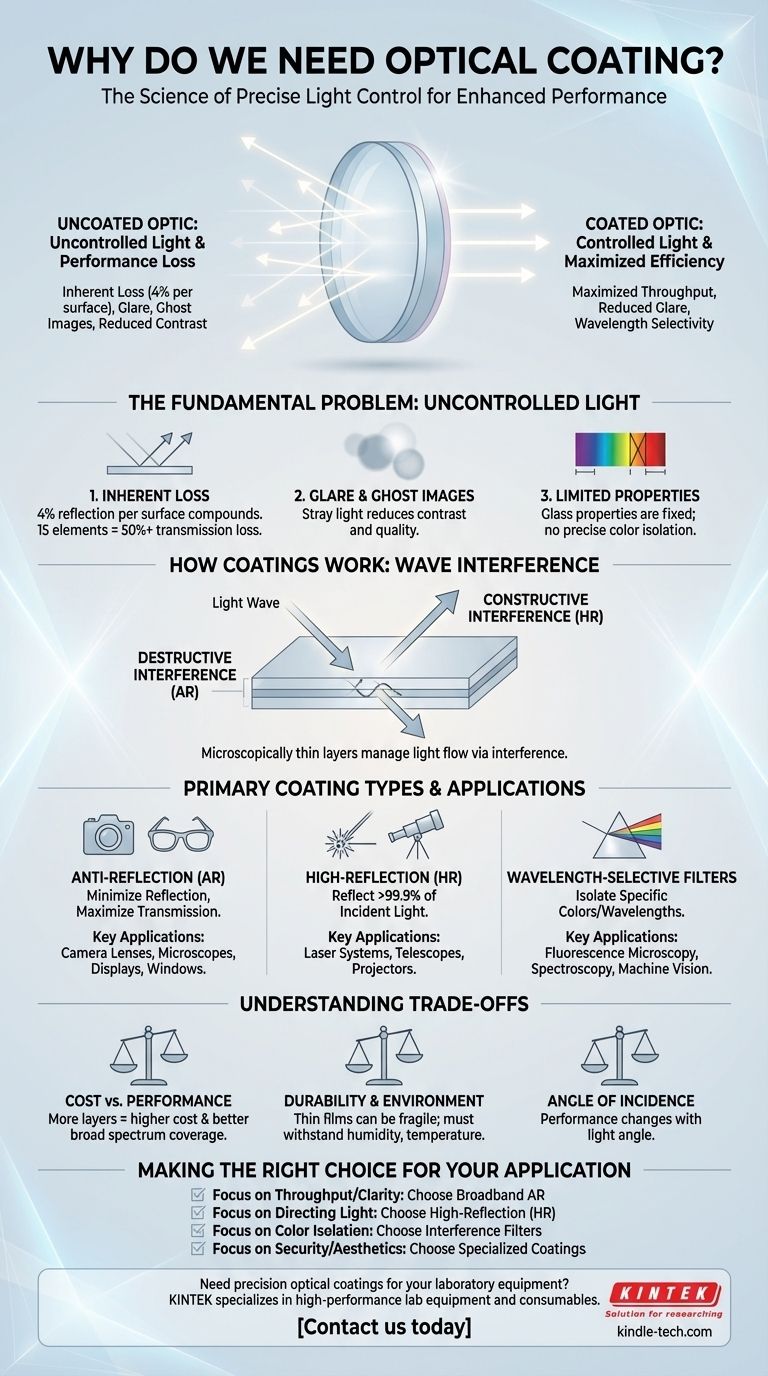

At its core, an optical coating is a tool for control. We need optical coatings to precisely manipulate how light interacts with the surface of an optical component, such as a lens or mirror. Without them, light reflects, transmits, and scatters in an uncontrolled and often undesirable way, leading to significant performance degradation.

Uncoated optics are fundamentally inefficient. Optical coatings are the enabling technology that transforms a simple piece of glass into a high-performance instrument by precisely managing the flow of light to reduce glare, maximize throughput, or isolate specific colors.

The Fundamental Problem: Uncontrolled Light

When light travels from one medium to another, such as from air into glass, a portion of that light is always reflected. This physical reality creates several problems in any optical system.

Inherent Loss at Every Surface

A single, uncoated surface of common glass reflects about 4% of the light that hits it. While this seems small, it compounds catastrophically in complex systems.

A professional camera lens can have 15 or more individual elements. With two surfaces per element, that's over 30 surfaces where light is lost, potentially reducing total light transmission by more than 50%.

Glare and Ghost Images

This reflected light doesn't just disappear. It bounces between lens surfaces, creating "ghost" images and internal flare.

This stray light reduces image contrast, washes out colors, and degrades the overall quality of the image or signal.

Limited Material Properties

The inherent optical properties of a material like glass are fixed. We cannot change how the glass itself interacts with different wavelengths (colors) of light.

To create components that selectively pass or block certain colors, we need a more flexible solution than just the bulk material itself.

How Optical Coatings Solve the Problem

Optical coatings consist of one or more microscopically thin layers of different materials deposited onto the optical surface. Their power comes from a physical principle called wave interference.

The Principle of Wave Interference

Light behaves as a wave. By applying ultra-thin layers, we can create multiple reflecting surfaces very close together.

Light waves reflecting off these different layer boundaries can be made to either cancel each other out (destructive interference) or reinforce each other (constructive interference).

Anti-Reflection (AR) Coatings

AR coatings are engineered so that light waves reflecting from the coating's layers interfere destructively. They effectively cancel each other out.

This minimizes reflection and maximizes the amount of light that passes through the optic. This is the solution for preventing signal loss and glare in lenses, windows, and display screens.

High-Reflection (HR) Coatings

Conversely, High-Reflection (HR) coatings, often called dielectric mirrors, use constructive interference.

The layers are designed to make all the reflected light waves align perfectly, creating a surface that can reflect over 99.9% of the incident light. This is critical for applications like steering laser beams.

Wavelength-Selective Filters

By precisely controlling the thickness and material of each layer, we can make these interference effects highly dependent on the wavelength of light.

This allows us to create cut-off filters that transmit light below a certain wavelength and block light above it, or bandpass filters that only transmit a very narrow range of colors. These are essential for scientific instruments, medical devices, and machine vision.

Understanding the Trade-offs

Optical coatings are not a universal solution. Choosing the right one requires balancing competing factors.

Cost vs. Performance

A simple, single-layer AR coating is inexpensive but is only highly effective for a narrow band of colors.

A complex, multi-layer broadband AR coating works across the entire visible spectrum but is significantly more difficult and expensive to produce. The number of layers directly impacts the cost and performance.

Durability and Environment

Coatings are, by nature, very thin films and can be susceptible to damage. Some coatings are soft and easily scratched, while others may degrade with exposure to humidity or high temperatures.

The coating must be robust enough for its intended environment, whether it's a protected lab or a rugged outdoor camera.

Angle of Incidence Sensitivity

The performance of many coatings, especially interference filters, is highly dependent on the angle at which light strikes the surface.

A filter designed to pass a specific color at a normal (0°) angle of incidence may pass a different color when tilted. This must be accounted for in the optical design.

Making the Right Choice for Your Application

The specific coating you need is dictated entirely by your primary goal.

- If your primary focus is maximizing throughput and image clarity (e.g., camera lenses, microscope objectives): You need broadband Anti-Reflection (AR) coatings to minimize light loss and ghosting at every surface.

- If your primary focus is efficiently directing light (e.g., laser systems, projectors, telescopes): You need High-Reflection (HR) dielectric mirror coatings to steer beams with minimal energy loss.

- If your primary focus is isolating specific wavelengths (e.g., fluorescence microscopy, spectroscopy, 3D scanning): You need specialized bandpass, longpass, or shortpass interference filters to separate the signal from unwanted light.

- If your primary focus is security or aesthetics (e.g., banknotes, architectural glass): You may require specialized coatings designed to create effects like color-shifting, which are difficult to replicate.

Ultimately, optical coatings are what elevate optics from a passive component to an active, precisely engineered tool.

Summary Table:

| Coating Type | Primary Function | Key Applications |

|---|---|---|

| Anti-Reflection (AR) | Minimize reflection, maximize light transmission | Camera lenses, microscope objectives, display screens |

| High-Reflection (HR) | Reflect over 99.9% of incident light | Laser systems, telescopes, projectors |

| Wavelength-Selective Filters | Isolate specific colors/wavelengths | Fluorescence microscopy, spectroscopy, machine vision |

Need precision optical coatings for your laboratory equipment? KINTEK specializes in high-performance lab equipment and consumables, providing optical coating solutions that enhance light control, reduce glare, and improve signal clarity for your specific application. Whether you require anti-reflection coatings for maximum throughput or wavelength-selective filters for precise color isolation, our expertise ensures optimal performance and durability. Contact us today to discuss how we can elevate your optical systems!

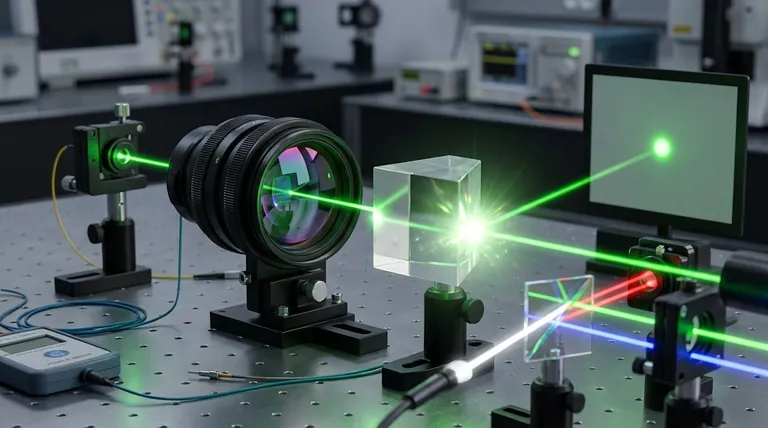

Visual Guide

Related Products

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Infrared Thermal Imaging Temperature Measurement Double-Sided Coated Germanium Ge Lens

- Infrared High Resistance Single Crystal Silicon Lens

People Also Ask

- What are the two methods that can be used to prevent corrosion of a metal? Barrier vs. Sacrificial Protection Explained

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What is the container that holds the metal source material called in e-beam evaporation? Ensure Purity and Quality in Your Thin-Film Deposition

- How thick is the sputter coating for SEM? Achieve Optimal Imaging & Analysis

- Can I solder copper to copper without flux? The Critical Role of Flux for a Strong Bond