To be definitive, autoclaving is performed at 121°C because this is the minimum temperature, achieved using pressurized steam, required to reliably destroy the most heat-resistant life forms on Earth: bacterial endospores. While boiling water at 100°C kills most microbes, it is insufficient for true sterilization, as these resilient spores can easily survive. The elevated temperature of 121°C ensures the rapid and complete denaturation of essential proteins, guaranteeing the elimination of all microorganisms.

The core principle is simple: standard pressure limits water to 100°C, which isn't hot enough for absolute sterility. By using pressure to raise the boiling point of water to 121°C, an autoclave creates an environment of superheated steam that can destroy even the toughest bacterial spores.

The Science of Steam Sterilization

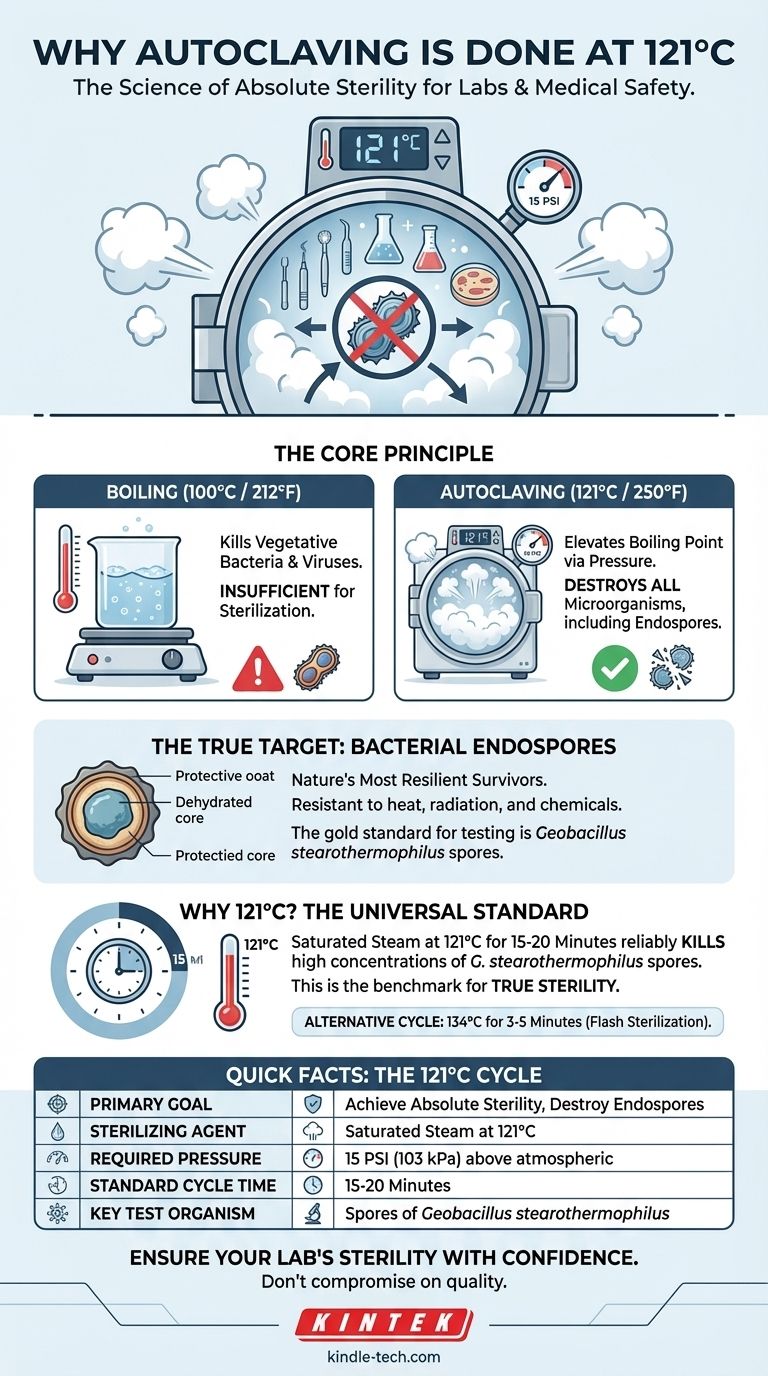

To understand the importance of 121°C, we must first distinguish between simple boiling and true steam sterilization. They are fundamentally different processes with different outcomes.

Beyond Boiling: Why 100°C Isn't Enough

Boiling water at 100°C (212°F) is a method of disinfection, not sterilization. It is effective at killing vegetative bacteria and viruses.

However, it cannot reliably kill bacterial endospores, which are dormant, highly protected structures produced by certain bacteria to survive extreme environmental stress.

The Critical Role of Pressure

The sterilizing agent in an autoclave is not the pressure itself. The pressure serves a single, critical purpose: to elevate the boiling point of water.

At standard atmospheric pressure, water boils at 100°C. By increasing the pressure inside the sealed autoclave chamber to approximately 15 psi (pounds per square inch) or 103 kPa above atmospheric pressure, the boiling point of water is raised to 121°C (250°F).

How Moist Heat Destroys Microbes

This superheated, saturated steam is the key to an autoclave's effectiveness. Moist heat is far more efficient at transferring thermal energy than dry heat (like in an oven).

The steam condenses on cooler items in the chamber, rapidly transferring heat and fatally denaturing and coagulating the essential proteins and enzymes that all microorganisms, including spores, need to live.

The True Target: Bacterial Endospores

The entire standard for autoclaving is built around defeating one specific type of adversary: the bacterial endospore.

Nature's Most Resilient Survivors

Endospores have tough outer coats and dehydrated cores, making them extraordinarily resistant to heat, radiation, and chemicals. They can survive in a dormant state for years.

Failure to eliminate them means an object is not sterile, posing a significant risk of contamination in medical, research, and pharmaceutical settings.

Geobacillus stearothermophilus: The Gold Standard

To validate that an autoclave is working correctly, operators use biological indicators. These indicators contain spores of a specific, non-pathogenic, and extremely heat-resistant bacterium: Geobacillus stearothermophilus.

This organism is the benchmark. If a cycle is proven to kill G. stearothermophilus spores, it is considered effective for sterilizing against all other microbial life.

Why 121°C is the Kill Temperature

Through extensive validation, it was determined that exposure to saturated steam at 121°C for a sufficient duration (typically 15 minutes) reliably kills even a high concentration of G. stearothermophilus spores.

This established the 121°C, 15-minute cycle as the universally accepted standard for achieving sterility.

Understanding the Trade-offs

While 121°C is the standard, it's crucial to understand the relationship between the three key variables: time, temperature, and pressure.

The Relationship Between Time and Temperature

Sterilization is a function of both temperature and time. While 121°C for 15 minutes is standard, other cycles exist.

For example, increasing the temperature to 134°C can achieve sterilization in as little as 3-5 minutes. This is often used for heat-stable medical instruments in a "flash" sterilization cycle.

Potential Damage to Materials

The intense heat and pressure of autoclaving can damage certain materials. Heat-sensitive plastics may melt, sharp instruments can become dull, and some chemical solutions may degrade.

It is critical to ensure that any item placed in an autoclave is compatible with the process.

Common Autoclave Failures

The most common reason for a failed sterilization cycle is trapped air. If air is not properly evacuated from the chamber, it creates cold spots where steam cannot penetrate, preventing items from reaching the target temperature. Modern autoclaves have vacuum cycles to prevent this.

Making the Right Choice for Your Goal

Selecting the correct autoclave cycle depends entirely on your specific objective and the materials you are processing.

- If your primary focus is routine sterilization of lab media, glassware, or waste: The standard 121°C for 15-20 minutes is the validated, reliable, and most common choice.

- If your primary focus is rapid sterilization of durable surgical instruments: A higher temperature cycle, such as 134°C for 3-5 minutes, may be more efficient if your equipment supports it.

- If you are validating your autoclave's performance: You must use biological indicators containing G. stearothermophilus spores to prove that your cycles are achieving a complete kill.

Understanding the principles behind the 121°C standard transforms autoclaving from a routine task into a guaranteed outcome of absolute sterility.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Goal | Achieve absolute sterility by destroying all microorganisms, including bacterial endospores. |

| Sterilizing Agent | Saturated steam at 121°C (250°F). |

| Required Pressure | 15 psi (103 kPa) above atmospheric pressure. |

| Standard Cycle Time | 15-20 minutes at 121°C. |

| Key Test Organism | Spores of Geobacillus stearothermophilus. |

| Common Alternative | 134°C for 3-5 minutes (flash sterilization). |

Ensure Your Lab's Sterility with Confidence

Achieving true sterility is non-negotiable for reliable research, pharmaceutical production, and medical safety. The standard 121°C autoclave cycle is validated to destroy even the most resilient bacterial spores, guaranteeing your work is free from contamination.

KINTEK specializes in providing reliable lab equipment and consumables to meet your precise sterilization needs. Whether you require a new autoclave, validation services, or expert advice on the best cycle for your materials, our team is here to support your laboratory's success.

Don't compromise on sterility. Contact KINTEK today to find the perfect autoclave solution for your lab!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What criteria must be followed when loading the autoclave to help ensure sterility will be achieved? Master the Key to Reliable Sterilization

- What substance Cannot be sterilized in an autoclave? A Guide to Protecting Heat-Sensitive Materials

- Can you autoclave surgical instruments? Master the Gold Standard for Sterilization

- What are the design requirements for a corrosion-resistant autoclave? Expert Solutions for Scheelite Leaching

- What are the primary advantages of using an autoclave molding process? Unlock Elite Performance for Composites

- Can an autoclave reach temps as high as 121 degrees Celsius? The Definitive Guide to Steam Sterilization

- What is the function of a laboratory autoclave in Ti-6Al-4V alloy preparation? Ensure Sterile Experimental Integrity