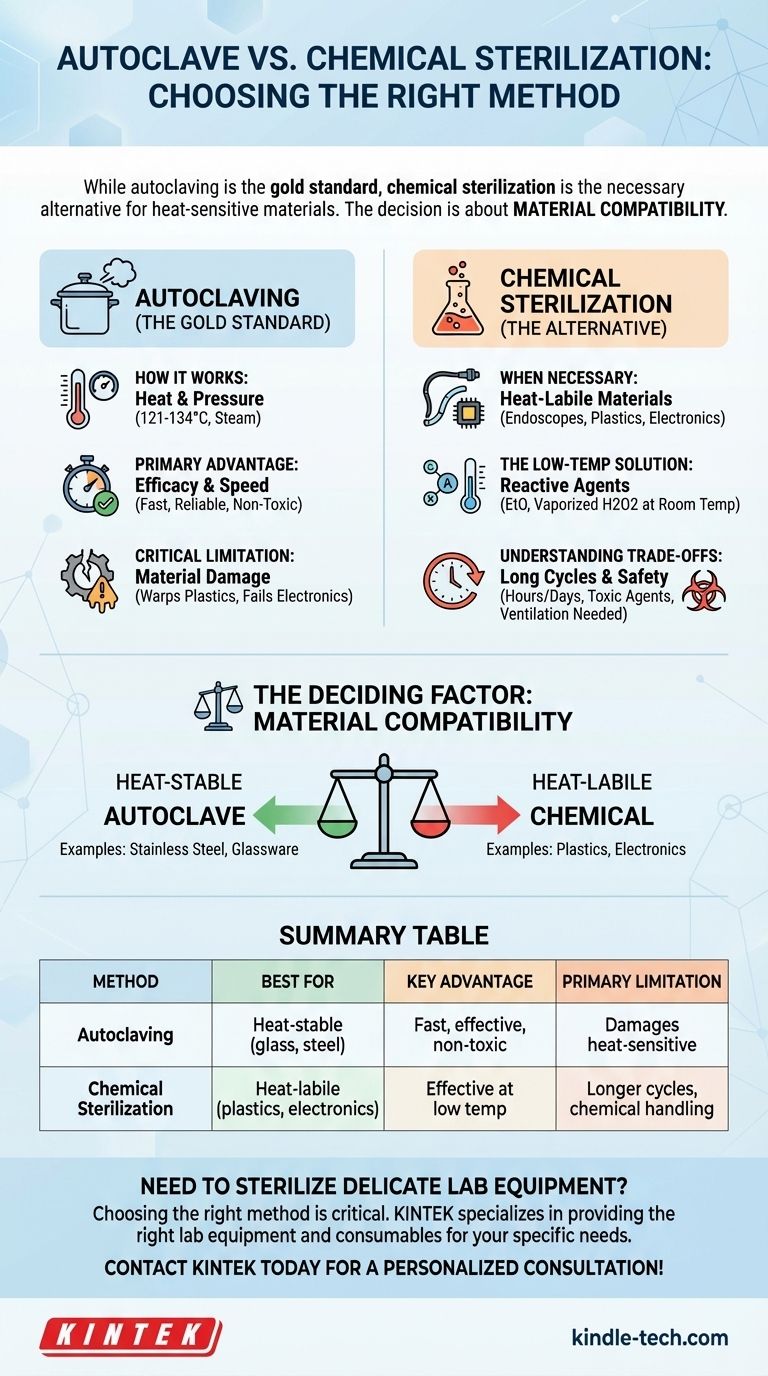

While autoclaving is the gold standard for sterilization, its reliance on high-pressure steam makes it unsuitable for many materials. Chemical sterilization is used as the necessary alternative for items that would be destroyed by the intense heat and pressure of an autoclave, such as delicate electronics, certain plastics, and complex medical instruments.

The decision between autoclaving and chemical sterilization is not about superiority, but material compatibility. Autoclaves are the preferred method for their speed and efficiency, but chemical methods are essential for sterilizing heat-sensitive items that would otherwise be damaged or destroyed.

The Principle of Autoclave Sterilization

How It Works: Heat and Pressure

An autoclave functions like a sophisticated pressure cooker. It uses steam pressurized to well above atmospheric pressure, which allows the steam to reach temperatures (typically 121-134°C) far hotter than boiling water.

This combination of intense heat and moisture is extremely effective at denaturing the proteins and enzymes essential for microbial life, killing even resilient bacterial spores.

The Primary Advantage: Efficacy and Speed

For materials that can withstand the conditions, autoclaving is the preferred method. It is fast, highly reliable, penetrates materials well, and leaves behind no toxic residue, as the sterilizing agent is simply water.

The Critical Limitation: Material Damage

The very forces that make an autoclave effective—high heat and pressure—are also its primary limitation. Many modern medical and laboratory devices cannot survive the process.

This includes most plastics which can warp or melt, complex electronics which will fail, and delicate optical instruments that can be damaged.

When Chemical Sterilization is Necessary

Defining Heat-Labile Materials

The term heat-labile (or heat-sensitive) refers to any material that physically or functionally degrades when exposed to high temperatures. This category is the primary driver for using chemical sterilization.

Common examples include flexible endoscopes, plastic tubing, power tools used in surgery, and items containing electronic components.

The Low-Temperature Alternative

Chemical sterilization achieves the same goal—the complete elimination of microorganisms—but does so at or near room temperature.

It relies on reactive chemical agents, often in a gaseous state, to permeate the item and destroy microbial life without the need for destructive heat.

Common Chemical Sterilants

While several methods exist, common examples include using Ethylene Oxide (EtO) or vaporized hydrogen peroxide. These gases can effectively sterilize items within a sealed chamber over a longer cycle time.

Understanding the Trade-offs

Cycle Time and Complexity

Autoclave cycles are typically fast, often completed in under an hour. Chemical sterilization cycles are significantly longer, sometimes taking many hours, especially when you include the necessary post-cycle aeration to safely remove residual chemicals.

Safety and Toxicity

The primary agent in an autoclave is steam, which is non-toxic. In contrast, chemical sterilants like Ethylene Oxide are toxic and carcinogenic, requiring strict ventilation and safety protocols to protect personnel.

Cost and Compatibility

While an autoclave may be cheaper to operate on a per-cycle basis, this is irrelevant if the item being sterilized is destroyed.

The higher cost and complexity of chemical sterilization are justified by its ability to safely process high-value, heat-sensitive equipment that would otherwise need to be replaced.

Making the Right Choice for Your Materials

Your choice hinges entirely on the composition of the item you need to sterilize. There is no single "best" method, only the most appropriate one for the task.

- If your primary focus is sterilizing heat-stable items (e.g., stainless steel surgical tools, glassware, media): The autoclave is the superior choice for its speed, reliability, and safety.

- If your primary focus is sterilizing heat-sensitive items (e.g., plastics, electronics, flexible endoscopes): Chemical sterilization is the only viable option to achieve sterility without causing irreversible damage.

Understanding this fundamental distinction between material robustness and process requirements is the key to effective and safe sterilization.

Summary Table:

| Sterilization Method | Best For | Key Advantage | Primary Limitation |

|---|---|---|---|

| Autoclaving | Heat-stable items (glass, stainless steel) | Fast, highly effective, non-toxic | Damages heat-sensitive materials |

| Chemical Sterilization | Heat-labile items (plastics, electronics, endoscopes) | Effective at low temperatures | Longer cycle times, chemical handling required |

Need to Sterilize Delicate Lab Equipment?

Choosing the right sterilization method is critical for protecting your valuable laboratory instruments. At KINTEK, we specialize in providing the right lab equipment and consumables to meet your specific sterilization needs, whether you require robust autoclaves or compatible systems for sensitive devices.

Let our experts help you select the perfect solution to ensure sterility without compromising your equipment's integrity. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- Why is a high-pressure autoclave essential for TiO2 synthesis? Master Hydrothermal Nanomaterial Engineering

- What are the risks of using an autoclave? Avoid Severe Burns and Sterilization Failures

- How long does it take to autoclave instruments? Get the Full Breakdown for Effective Sterilization

- What are the primary functions of high-pressure autoclaves and circulating loop systems in simulating IASCC?

- What are the advantages of autoclaving sterilization? Achieve Unmatched Sterilization for Your Lab Equipment

- Which factors contribute to successful sterilization using an autoclave? Master the 3 Keys to Sterility

- How long does an autoclave cycle take? Understanding the 25-60 Minute Sterilization Process

- What is the best sterilization method in microbiology? Match the Method to Your Material for Optimal Results