In the simplest terms, laboratory grinding is the critical process of reducing the size of a sample's particles. This is an indispensable step for preparing materials for analysis because it ensures the sample is uniform and consistent, which is the foundation of reliable and reproducible experimental results.

The fundamental goal of grinding is not just to make things smaller, but to create a homogeneous sample. This uniformity ensures that any small portion taken for analysis is a true representation of the entire batch, eliminating variables that could otherwise invalidate your results.

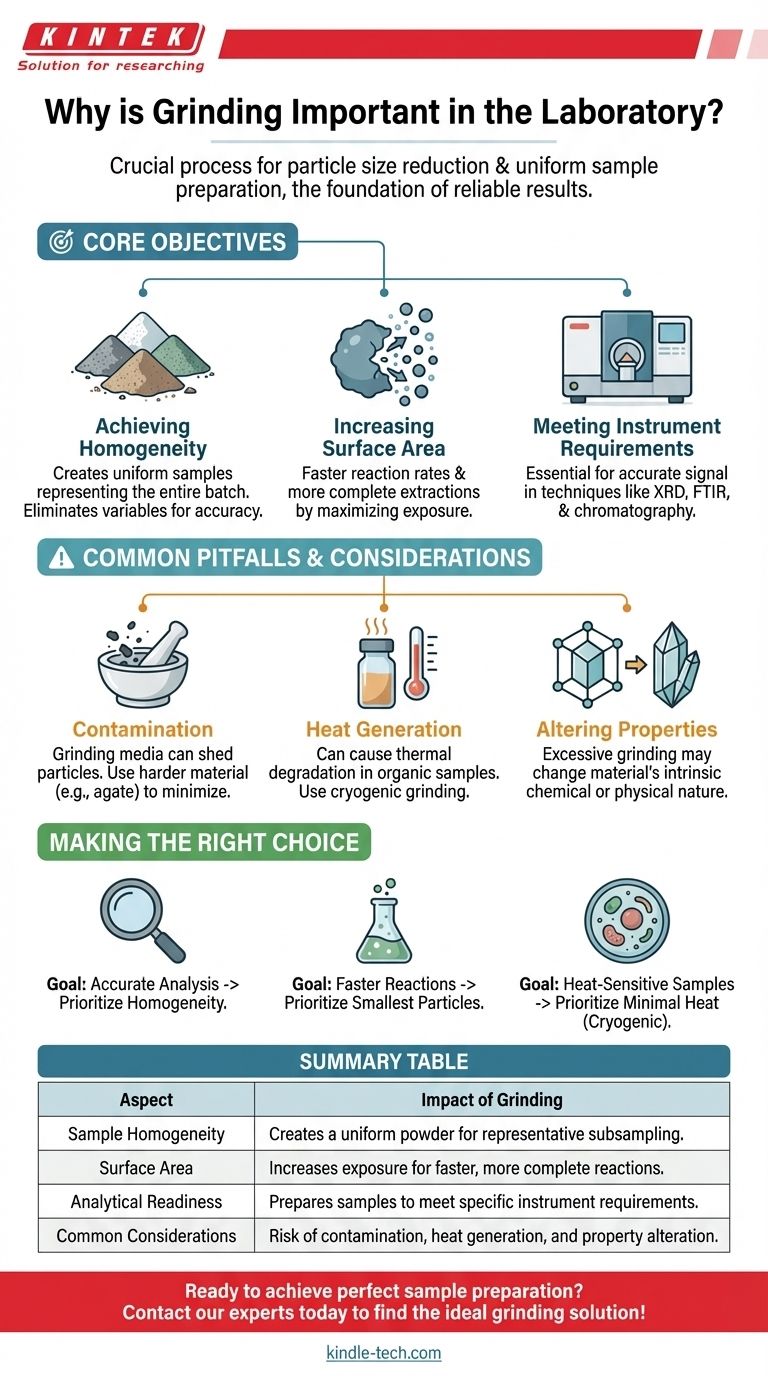

The Core Objectives of Laboratory Grinding

Grinding is a foundational technique that directly impacts the quality and reliability of subsequent scientific analysis. Its importance stems from two primary physical changes it imparts to the sample material.

Achieving Homogeneity for Representative Samples

A bulk sample, such as rock, soil, or biological tissue, is rarely uniform. Different components may be distributed unevenly throughout the material.

Grinding and mixing create a homogeneous powder. This ensures that any subsample you draw for an experiment contains the same composition as the original material, which is paramount for accuracy.

Without this step, your results would vary wildly depending on which part of the sample you happened to select, making the data unreliable.

Increasing Surface Area for Better Reactions

Breaking a large particle into many smaller ones drastically increases the total surface area exposed to the surrounding environment.

This is critical for processes like chemical reactions or extractions. A larger surface area allows solvents or reactants to interact more efficiently with the sample, leading to faster reaction rates and more complete extractions.

Meeting Requirements for Analytical Instruments

Many modern analytical instruments have strict requirements for sample input.

Techniques like X-ray diffraction (XRD), infrared spectroscopy (FTIR), and various forms of chromatography often require finely powdered, homogeneous samples to produce a clear and accurate signal. Improperly prepared samples can lead to poor data or even damage the instrument.

Common Pitfalls and Considerations

While essential, the grinding process itself can introduce errors if not performed correctly. An awareness of the potential trade-offs is crucial for maintaining sample integrity.

Contamination from Grinding Media

The tools used for grinding—such as a mortar and pestle or the balls in a ball mill—can shed microscopic particles into your sample.

Using a harder material for the grinding tool than the sample itself (e.g., an agate mortar for a softer mineral) minimizes this risk. Choosing the wrong media can introduce contaminants that interfere with later analysis.

Heat Generation and Sample Degradation

The mechanical friction of grinding generates heat. For robust inorganic materials, this is rarely an issue.

However, for heat-sensitive organic or biological samples, this heat can cause thermal degradation, altering the chemical structure of the very molecules you intend to study. Techniques like cryogenic grinding, which uses liquid nitrogen, are employed to prevent this.

Altering Material Properties

The physical act of grinding can sometimes change the properties of a material. For example, excessive grinding can alter the crystalline structure of a substance, which could affect its analysis by techniques like XRD.

The goal is to reduce particle size without fundamentally changing the material's intrinsic chemical or physical nature.

Making the Right Choice for Your Goal

The proper grinding technique depends entirely on your sample type and what you intend to measure.

- If your primary focus is accurate elemental or chemical analysis: Prioritize achieving perfect homogeneity and select grinding media that will not contaminate your sample.

- If your primary focus is speeding up a chemical reaction or extraction: Emphasize creating the smallest possible particles to maximize surface area, while being mindful of potential heat generation.

- If your primary focus is analyzing a heat-sensitive biological sample: Use methods that minimize heat, such as cryogenic grinding, to preserve the integrity of the molecules.

Ultimately, proper grinding transforms an unpredictable raw sample into a reliable and measurable material, forming the bedrock of sound scientific investigation.

Summary Table:

| Aspect | Impact of Grinding |

|---|---|

| Sample Homogeneity | Creates a uniform powder for representative subsampling. |

| Surface Area | Increases exposure for faster, more complete reactions. |

| Analytical Readiness | Prepares samples to meet specific instrument requirements. |

| Common Considerations | Risk of contamination, heat generation, and property alteration. |

Ready to achieve perfect sample preparation?

Proper grinding is the foundation of reliable data. KINTEK specializes in high-quality lab equipment and consumables, including a range of mills and grinding media designed to deliver consistent, contamination-free results for your specific application—from robust inorganic materials to heat-sensitive biological samples.

Contact our experts today to find the ideal grinding solution for your laboratory's needs and ensure the integrity of your analysis from the very first step.

Visual Guide

Related Products

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

People Also Ask

- What is the laboratory apparatus used for grinding? Find the Perfect Mill for Your Sample

- What is the particle size for XRD analysis? Optimize Your Results with the Right Preparation

- Why is an alumina mortar used for grinding dried Yttrium Oxide precursor materials? Ensure Maximum Purity and Quality

- What is the primary purpose of using grinding tools like agate mortars? Optimize LTO Electrode Performance

- What are the different types of laboratory mills? Choose the Right Grinder for Your Sample Material