Introduction to Molecular Distillation

Principle of Molecular Distillation

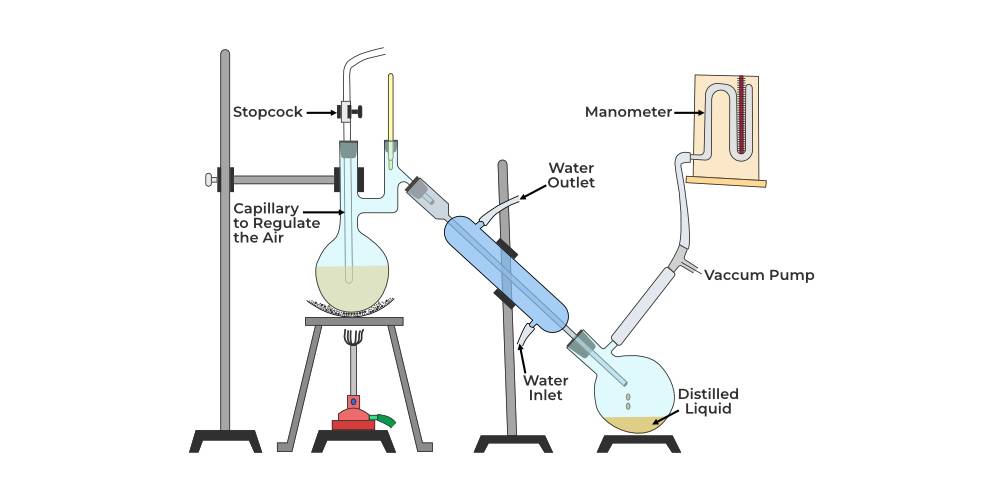

Molecular distillation is a specialized separation and purification technique that operates under high vacuum conditions. This method leverages the significant differences in the evaporation rates of various components within a liquid mixture to achieve separation. The process involves several key steps: sublimation, boiling, and condensation, all of which are meticulously controlled by adjusting temperature and pressure.

Under high vacuum, the average free path of vapor molecules becomes greater than the distance between the evaporation surface and the condensation surface. This allows molecules to travel without colliding, enabling the separation of components based on their distinct evaporation rates. The principle of molecular distillation can be further understood through the concept of molecular mean free path. According to thermodynamic principles, the mean free path ( L ) of molecules is given by the equation:

[ L = 0.707K \cdot \frac{T}{\pi d^2 P} ]

where:

- ( K ) is the Boltzmann constant,

- ( T ) is the temperature,

- ( d ) is the effective molecular diameter,

- ( P ) is the pressure in the molecular space.

This equation highlights that different molecules, due to their varying effective diameters, have different mean free paths. By strategically placing a condensation surface at a distance less than the mean free path of lighter molecules but greater than that of heavier ones, molecular distillation can effectively separate the mixture. Lighter molecules, with shorter mean free paths, condense on the surface, while heavier molecules, with longer mean free paths, pass by and return to the original liquid level. This differential condensation mechanism is the crux of molecular distillation, enabling the precise and efficient purification of target substances.

Process Flow of Molecular Distillation Technology

The process of molecular distillation is a meticulously controlled sequence designed to achieve high purity and efficiency. It begins with the mixture feeding, where the feed material is carefully degassed to remove any volatile components, ensuring a clean starting point for the distillation process. This step is crucial as it prevents contamination and enhances the overall purity of the final product.

Following the degassing, the material is introduced into a spinning disc pre-heated to the optimal temperature. The rapid spinning action spreads the material into a thin film, which is then subjected to controlled heating. This heating and evaporation stage is critical, as it ensures that the material evaporates quickly, typically within a fraction of a second, thereby minimizing thermal degradation.

Once evaporated, the vapors move towards the condenser, where they undergo separation and purification. The high vacuum conditions, maintained at a pressure of 10^-3 Torr, facilitate the separation of molecules based on their volatility, ensuring that only the desired compounds reach the condenser. This stage is where the true purification of the material occurs, filtering out impurities and ensuring the desired product is isolated.

The condensation and collection phase follows, where the purified vapors condense on the outer extremes of the shell. Due to gravity, the condensed liquid slowly flows into the collecting vessel, ready for further processing or packaging. This step ensures that the final product is collected in a pure and concentrated form, ready for use in various applications.

Finally, the waste removal and recycling process is carried out. Any residual matter that does not condense is collected in gutters around the spinning disc and then transferred to a separate collecting vessel. These residues can be recycled or disposed of safely, ensuring that the process is not only efficient but also environmentally responsible.

Throughout the entire process, the low-temperature and high-vacuum conditions prevent thermal decomposition and oxidation, preserving the integrity and quality of the final product. This meticulous control over temperature and pressure makes molecular distillation a highly effective technique for achieving high purity in various industries, including food processing, pharmaceuticals, and daily-use chemicals.

Applications in Daily-Use Chemicals

Personal Care Products

Molecular distillation plays a pivotal role in the production of personal care products, particularly in the creation of perfumes and skincare items. This advanced separation technique ensures not only the longevity and stability of these products but also the extraction of high-quality ingredients that are essential for their efficacy and appeal.

For instance, in the formulation of perfumes, molecular distillation is employed to isolate and purify aromatic compounds, ensuring that the fragrance remains stable and potent over time. Similarly, in skincare products, this technology is used to extract active ingredients such as essential oils and vitamins, which are crucial for their therapeutic benefits.

The process of molecular distillation involves precise control of temperature and pressure, which allows for the separation of components based on their boiling points. This results in the purification of target substances to a high degree of purity, free from impurities that could compromise the quality and effectiveness of the final product.

In summary, molecular distillation is an indispensable tool in the manufacturing of personal care products, contributing significantly to their quality, stability, and overall performance in the market.

Detergents Production

Molecular distillation plays a pivotal role in the production of detergents, significantly enhancing their cleaning efficacy and stability. This advanced purification technique meticulously removes impurities from key ingredients, such as surfactants and enzymes, which are crucial for the detergents' performance. By isolating and concentrating these active components, molecular distillation ensures that detergents maintain their effectiveness across a spectrum of water conditions, from hard to soft water.

Moreover, the process of molecular distillation contributes to the overall quality and longevity of detergent formulations. It not only purifies but also preserves the integrity of sensitive ingredients, preventing degradation that could otherwise occur during conventional distillation methods. This preservation is particularly critical in maintaining the detergents' stability over extended periods, thereby enhancing consumer satisfaction and product reliability.

In essence, molecular distillation acts as a cornerstone in the production of high-performance detergents, enabling manufacturers to deliver products that consistently meet consumer expectations for cleanliness and reliability.

Advantages of Molecular Distillation

High Purity and Efficiency

Molecular distillation stands out as a highly efficient method for achieving high-purity target substances at low operational temperatures. This technique not only ensures the preservation of delicate chemical structures but also significantly reduces energy consumption, thereby lowering operational costs. The process leverages the principle of differential boiling points, allowing for the precise separation of compounds without subjecting them to extreme heat, which is often detrimental to their integrity.

By operating at reduced temperatures, molecular distillation minimizes the risk of thermal degradation, a common issue in traditional distillation methods. This is particularly advantageous in the production of daily-use chemicals where maintaining the integrity and efficacy of ingredients is paramount. For instance, in the creation of personal care products like skincare items and perfumes, the ability to extract and purify active ingredients without compromising their stability and potency is crucial.

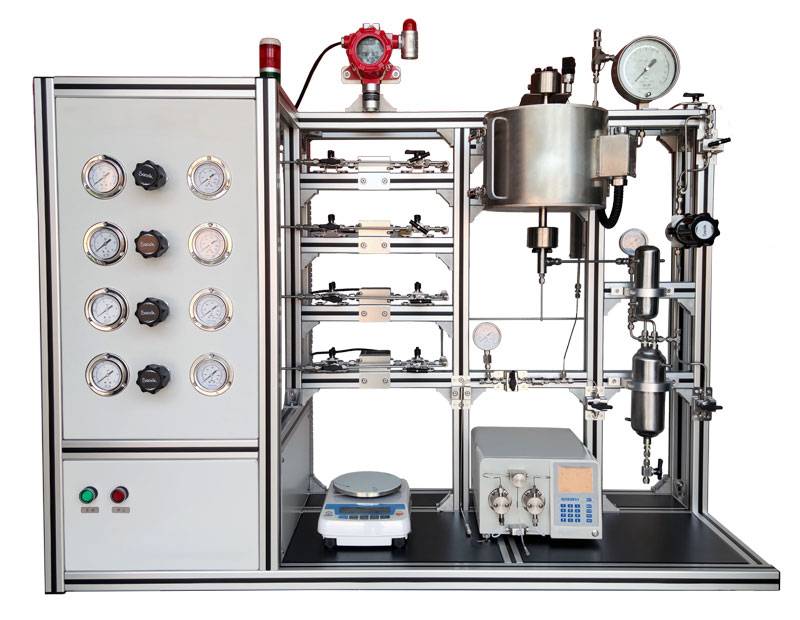

Moreover, the efficiency of molecular distillation in terms of energy usage and cost reduction is further enhanced by its streamlined process flow. The technology involves a series of carefully controlled steps, including mixture feeding, heating and evaporation, separation and purification, and condensation and collection. Each stage is meticulously designed to optimize output while minimizing waste, contributing to both economic and environmental benefits.

In summary, molecular distillation's ability to deliver high-purity substances efficiently at low temperatures not only enhances the quality of daily-use chemical products but also makes the production process more sustainable and cost-effective.

Controllability and Adaptability

Molecular distillation technology offers a high degree of controllability and adaptability, making it a versatile tool in the daily-use chemical industry. The process can be meticulously managed through the adjustment of critical parameters such as temperature and pressure. This fine-tuning capability allows for the optimization of distillation conditions to suit a wide array of mixtures and product specifications.

For instance, in the production of personal care products, the ability to precisely control temperature ensures that delicate aromatic compounds are not degraded, thereby preserving the quality and longevity of perfumes and skincare items. Similarly, in the manufacture of detergents, the adaptability of molecular distillation to different pressure settings enables the purification of key ingredients, enhancing both the cleaning efficacy and stability of the final product.

Moreover, the technology's adaptability extends to various chemical mixtures, allowing it to handle diverse product requirements efficiently. This versatility is particularly beneficial in industries where product consistency and quality are paramount, such as in the production of high-purity essential oils and specialized chemical compounds. By leveraging the controllability and adaptability of molecular distillation, manufacturers can achieve superior product outcomes while maintaining operational flexibility and efficiency.

Related Products

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask