Importance of Safety in Using Pressure Reactors

Understanding the specifications of your pressure reactor

Safety is paramount when conducting chemical reactions under pressurized conditions. It is important to carefully prepare your pressure reactor and lab safety equipment to prevent potential hazards that could be disastrous if left unchecked. Improper preparation can lead to minor problems escalating quickly when working under pressure.

To ensure safety when using a pressure reactor, it is crucial to understand the specifications of the reactor. Familiarize yourself with the chemical properties of the reactor material and ensure that it is chemically resistant enough to withstand the substances used in your reaction. Stainless steel pressure reactors are commonly used, but the chemical resistance may vary depending on the grade.

Another important consideration is the construction limitations of the pressure reactor. Check the integrity of the vessel, including the o-ring and joints where additional apparatus is connected. Ensure that the o-ring is made of a suitable material for your work.

It is also essential to know the vessel capacity of the pressure reactor. Never overfill the vessel, as this can lead to dangerous pressures. The vessel should not be filled to more than three-quarters of the free space, and in some cases, it may need to be filled even less. When heating a liquid in a closed vessel without sufficient capacity for expansion, the pressure can suddenly increase. This is particularly true for water and water solutions, which can expand up to three times their original volume when heated to the critical point.

Lastly, check the temperature and pressure rating of the pressure vessel. Ensure that the vessel has been tested and is rated for the intended temperature and pressure required. If the rating is insufficient, do not proceed with the work. Also, make sure to release any residual pressure in the vessel before opening it.

Considering the potential impacts on personnel and environment

Laboratory safety is not just about personal well-being; it also extends to the impact on personnel and the environment. Working with pressure reactors requires stringent safety procedures to prevent accidents and guarantee the integrity of the reactor vessels.

Specialized alloys or reinforced vessel designs may be necessary to build high-pressure reactors out of durable materials that can sustain the severe pressure. These measures ensure that the equipment is capable of handling the pressures involved and minimize the risk of accidents.

By prioritizing safety in the use of pressure reactors, the potential risks to personnel and the environment can be mitigated. Taking the time to understand the specifications of the reactor, considering construction limitations, and adhering to safety procedures will help prevent accidents and ensure the safe operation of pressure reactors.

In conclusion, high-pressure reactors have revolutionized chemical engineering by accelerating reactions and advancing industries such as pharmaceuticals, polymers, and material sciences. They have the capacity to change reaction rates, improve selectivity, and boost yields. As research and development continue, high-pressure reactors will play a crucial role in fostering innovation and enabling the manufacture of new materials and sustainable chemical solutions.

To ensure safety when working with pressure reactors, it is important to follow the ten simple steps for pressure safety in your laboratory:

- Refer to existing in-house guidance and be aware of all current and applicable laboratory safety rules.

- Familiarize yourself with the chemical properties of the pressure reactor material.

- Ensure the integrity of the o-ring and joints in the pressure reactor.

- Do not overfill the pressure vessel and be aware of the expansion properties of substances used.

- Check the temperature and pressure rating of the pressure vessel.

- Release any residual pressure in the vessel before opening it.

By following these steps, you can prioritize safety when working with pressure reactors in your laboratory and minimize the risk of accidents.

Guidelines for Laboratory Safety with Pressure Reactors

Referencing existing in-house safety guidelines

When working with pressure reactors, it is crucial to refer to existing in-house safety guidelines. This includes being aware of all current and applicable laboratory safety rules. It is important not to assume that nothing has changed and to refresh oneself on any particular safety precautions in the laboratory, especially in a pharma laboratory setting.

Understanding the construction limitations of the pressure reactor

Familiarize yourself with the chemical properties of the pressure reactor material. For example, stainless steel pressure reactors are common, but their chemical resistance varies from grade to grade. It is important to ensure that the metal is chemically resistant enough to handle the substances used in the reaction.

Checking links in the structure of the reactor

Before using the pressure reactor, it is essential to check the o-ring on the vessel and any joints where additional apparatus is connected to the head. These components must be in good condition and sound. It is also important to verify if the o-ring is made of a suitable material for the specific work being done.

Ensuring proper vessel capacity

One of the most commonly overlooked hazards when working with pressure reactors is overfilling the vessel. The vessel must never be filled to more than three-quarters of the free space, and in some cases, this must be reduced even further. Heating a liquid in a closed vessel without sufficient capacity for expansion can lead to dangerous pressures. Water and water solutions, in particular, can increase to as much as three times their original volume when heated to the critical point.

Understanding the temperature and pressure rating of the pressure reactor

Before conducting any reactions, it is crucial to check that the pressure vessel has been tested and is rated for the intended temperature and pressure. If the rating is insufficient, the work should not be carried out. Additionally, it is important to check for any residual pressure in the vessel before opening it to avoid any accidents.

In conclusion, laboratory safety with pressure reactors requires careful preparation and adherence to guidelines. By referencing existing in-house safety guidelines, understanding the construction limitations of the pressure reactor, checking links in the structure, ensuring proper vessel capacity, and understanding the temperature and pressure rating, you can minimize potential hazards and ensure a safe working environment. Remember, safety should always be the top priority when working with pressure reactors in the laboratory.

Maintaining Safety Standards while Using Pressure Reactors

Maintaining the pressure reactor

- Refer to existing in-house guidance and ensure you are aware of all current and applicable laboratory safety rules.

- Familiarize yourself with the chemical properties of the pressure reactor material and ensure it is chemically resistant enough for your reactions.

- Check the o-ring on the vessel and any joints for soundness and verify if they are made of suitable material.

Identifying by-products and potential loss of control

- Identify the by-products that will be produced as a result of your reaction and consider how they will behave.

- Anticipate circumstances under which the reaction could become uncontrollable and make plans to control the situation.

Safely scaling up reactions

- Start with small volumes when working with hazardous reactants, especially unfamiliar ones.

- Increase the volume only after establishing a safe path to do so.

Considering external safety factors

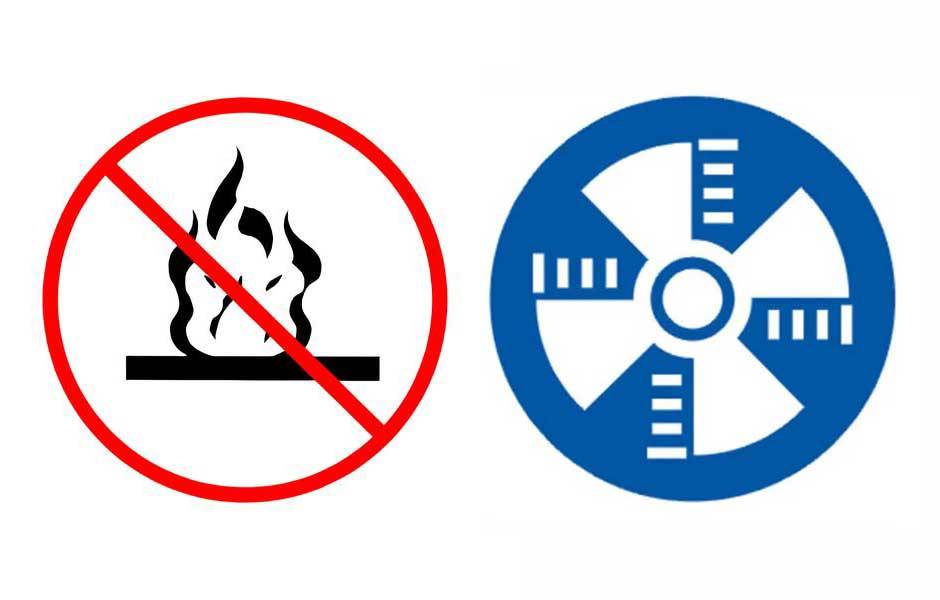

- Choose a well-ventilated location for setting up your reaction.

- Ideally, place the pressure reactor close to a fume hood or exhaust fan to discharge any gases safely.

- Avoid having naked flames in the vicinity of the pressure reactor.

Conducting a reality check and risk assessment

- Before starting the reaction, take a moment to run a risk assessment.

- Ensure you have all your personal protective equipment (PPE) on properly.

Remember, safety is paramount when working with pressure reactors. By following these steps and taking necessary precautions, you can minimize the risks associated with pressurized reactions.

Conclusion

In conclusion, ensuring safety when using pressure reactors in laboratories is of utmost importance. By understanding the specifications of the pressure reactor and considering the potential impacts on personnel and the environment, we can minimize risks and prevent accidents. Following guidelines such as referencing existing safety guidelines, understanding the construction limitations, checking links in the structure, ensuring proper vessel capacity, and knowing the temperature and pressure ratings are essential for maintaining safety standards. Additionally, maintaining the pressure reactor, identifying by-products and potential loss of control, safely scaling up reactions, considering external safety factors, and conducting reality checks and risk assessments are crucial steps towards a safe laboratory environment. By prioritizing safety, we can protect both ourselves and our surroundings. Stay safe!

Related Products

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box