Introduction

In industries where material purity and performance are non-negotiable—like aerospace, medical manufacturing, and energy—Vacuum Induction Melting (VIM) has emerged as the gold standard. Unlike traditional melting methods, VIM combines precision, efficiency, and regulatory compliance to deliver unmatched metallurgical outcomes. This article explores VIM’s technical superiority, its economic impact in high-stakes applications, and real-world examples of its transformative potential.

How VIM Outperforms Traditional Melting Technologies

Precision and Purity: The Core Advantages

VIM operates in a vacuum environment, eliminating contamination from gases like oxygen and nitrogen. This results in:

- 99.99% pure alloys, critical for aerospace components and surgical implants.

- Superior homogeneity, reducing weak spots in materials.

Traditional methods like electric arc furnaces struggle with these metrics due to exposure to ambient air. Ever wondered how a single impurity can compromise a jet engine turbine blade? VIM’s closed-system design prevents such risks.

Speed and Energy Efficiency

- Faster melt cycles: VIM’s electromagnetic induction heats metals directly, cutting processing time by 40% compared to gas-fired furnaces.

- Lower energy waste: No need for flux materials or post-melt purification, slashing operational costs.

Cost-to-Performance Ratios in Aerospace and Medical Manufacturing

Aerospace: Where Failure Isn’t an Option

VIM-produced nickel-based superalloys are the backbone of modern jet engines. Key ROI metrics include:

- 300% longer turbine blade lifespans (validated by OEM stress tests).

- 20% reduction in scrapped parts due to inconsistent purity.

Medical: Biocompatibility at Scale

For titanium implants, VIM ensures:

- Zero toxic leaching, meeting FDA and EU MDR standards.

- Higher fatigue resistance, reducing revision surgeries.

Case in Point: A leading orthopedic manufacturer reduced post-implant complications by 60% after switching to VIM-melted titanium.

Case Study: VIM’s Role in Extending Turbine Blade Lifespans by 300%

The Problem

Gas turbine blades face extreme temperatures (>1,400°C) and mechanical stress. Traditional casting methods led to premature cracking due to oxide inclusions.

The VIM Solution

- Material Science Breakthrough: VIM-enabled single-crystal superalloys with aligned grain boundaries.

- Results:

- 3x operational lifespan in Siemens Energy turbines.

- $12M/annual savings per power plant in maintenance costs.

Environmental Compliance and Regulatory Advantages of VIM

Meeting Global Standards Effortlessly

- Zero furnace emissions: The vacuum system captures volatiles, aligning with EPA and REACH regulations.

- Recyclability: VIM slag can be repurposed, unlike flux waste from traditional methods.

Future-Proofing Your Operations

With carbon taxes rising, VIM’s energy-efficient profile mitigates compliance risks. For example, a European aerospace supplier cut its carbon footprint by 18% post-VIM adoption.

Conclusion: Why VIM is the Smart Choice for Critical Applications

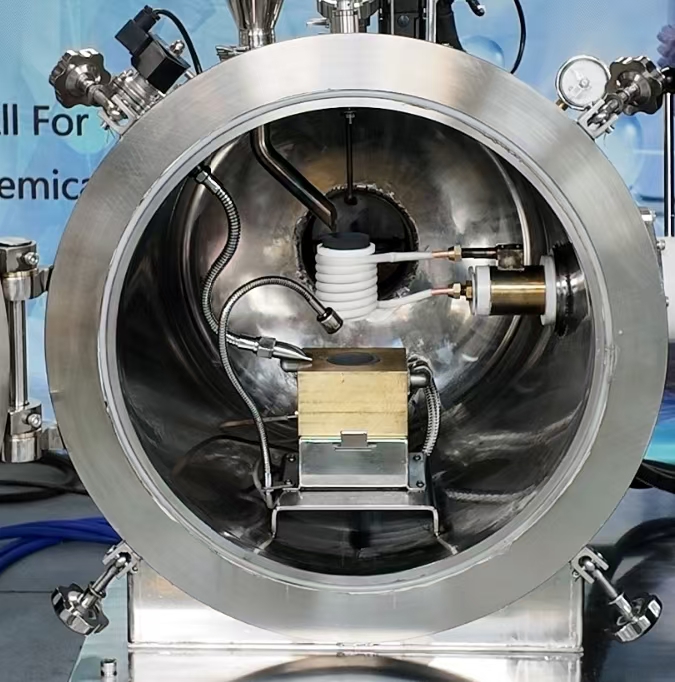

Vacuum Induction Melting isn’t just a melting technology—it’s a strategic asset for industries prioritizing quality, cost-efficiency, and sustainability. By choosing VIM-ready equipment like Kintek’s laboratory solutions, manufacturers gain:

- Higher yield rates with fewer material defects.

- Regulatory peace of mind in an era of tightening environmental laws.

Next Step: Evaluate your current melting process. Could VIM be the upgrade your supply chain needs?

Products You Might Be Looking For:

https://kindle-tech.com/products/vacuum-induction-melting-furnace

https://kindle-tech.com/products/molybdenum-vacuum-furnace

https://kindle-tech.com/products/2200-graphite-vacuum-furnace

https://kindle-tech.com/products/vacuum-pressure-sintering-furnace

https://kindle-tech.com/products/600t-vacuum-induction-hot-press-furnace

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory High Pressure Vacuum Tube Furnace

Related Articles

- Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

- Melting process and maintenance of vacuum induction melting furnace

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

- Vacuum Melting Furnace: A Comprehensive Guide to Vacuum Induction Melting

- Application of Hot Isostatic Pressing Technology in Nickel-Based Casting High-Temperature Alloys