Introduction to the Circulating Water Vacuum Pump

Common Misconceptions

Contrary to popular belief, the circulating water vacuum pump is not just another piece of equipment in the synthesis lab. Many individuals mistakenly assume that rotary evaporators or magnetic stirrers are the most frequently used tools, overshadowing the true utility of the circulating water vacuum pump. This oversight is largely due to the pump's discreet operation and the less glamorous tasks it performs. However, the reality is that the circulating water vacuum pump is indispensable, operating continuously and silently in the background, ensuring the smooth functioning of numerous experiments and processes. Its frequent use in a wide array of scenarios underscores its critical role, making it the unsung hero of the lab.

Frequency of Use

The circulating water vacuum pump is not just a piece of equipment; it is an integral part of the synthesis lab's daily routine. Its usage spans across numerous experiments and processes, making it a cornerstone of scientific research. Unlike other lab equipment that may be used intermittently, the pump operates consistently, often for extended periods, ensuring a stable vacuum environment essential for various synthesis techniques.

In many scenarios, the pump's role is indispensable. Whether it's facilitating the distillation of volatile compounds, aiding in the filtration of precipitates, or supporting the drying of samples, the pump's versatility is unmatched. Its continuous operation underscores its criticality, ensuring that researchers can maintain a consistent workflow without interruptions.

Moreover, the pump's widespread use is not confined to specific types of labs. From academic institutions to industrial research facilities, its presence is ubiquitous. This widespread adoption highlights its reliability and effectiveness, further cementing its status as a must-have tool in any synthesis lab.

Advantages of the Circulating Water Vacuum Pump

Simplicity and Practicality

The circulating water vacuum pump stands out in synthesis labs due to its straightforward design and minimal manufacturing precision requirements. This simplicity translates into ease of use and maintenance, making it a practical choice for daily laboratory operations. Unlike more complex equipment, the pump's basic structure reduces the learning curve for new users, ensuring that even those with limited experience can operate it effectively.

Moreover, the pump's low maintenance needs further enhance its practicality. Regular upkeep involves routine tasks such as changing the water, which are straightforward and do not require specialized technical knowledge. This not only saves time but also reduces operational costs, as there are no wearing parts or consumables to replace frequently. The combination of a simple design and minimal maintenance demands makes the circulating water vacuum pump a reliable and efficient tool in synthesis labs.

Versatility in Pumping Heads

The circulating water vacuum pump stands out for its flexibility in pumping head configurations. It can be set up in either desktop or vertical orientations, each offering distinct advantages depending on the specific needs of the laboratory. In desktop setups, the pump is easily accessible and can be conveniently monitored and adjusted during experiments. Conversely, vertical configurations save valuable bench space and are particularly useful in labs with limited room.

Moreover, these pumps can be deployed individually or in parallel arrangements, significantly enhancing their versatility. Individual use allows for focused, single-task operations, while parallel setups enable simultaneous multi-tasking, increasing efficiency and throughput. This dual capability makes the circulating water vacuum pump an invaluable asset in environments where multiple experiments or processes require vacuum conditions.

The adaptability of these pumps is further underscored by their compatibility with various experimental setups. Whether in a research lab, educational institution, or industrial setting, the pump's ability to switch between configurations ensures it can meet diverse operational requirements, reinforcing its status as a cornerstone of synthesis laboratory equipment.

Low Maintenance and Cost

The circulating water vacuum pump stands out for its minimal maintenance requirements and low operational costs. Unlike other laboratory equipment that may require frequent servicing or replacement of parts, this pump operates with simplicity. The primary maintenance task involves periodic water changes, ensuring the system remains clean and efficient.

Moreover, the pump's design eliminates the need for wearing parts or consumables, significantly reducing the long-term costs associated with its operation. This not only makes it a cost-effective choice for synthesis labs but also reduces the burden of managing and budgeting for frequent maintenance activities.

In summary, the circulating water vacuum pump's low maintenance and cost-effective operation contribute to its widespread use and reliability in synthesis labs.

Challenges and Disadvantages

Frequent Water Changes

Frequent water changes, particularly in vertical pumps, can be a significant hassle and a messy affair. This necessity arises due to the continuous operation of the pump, which results in the water becoming contaminated with various solvents and chemicals over time. As the water quality deteriorates, it can compromise the efficiency and performance of the pump, necessitating regular replacements.

The process of changing the water is not only time-consuming but also requires careful handling to avoid spillage and contamination of the lab environment. This routine maintenance task can disrupt ongoing experiments and add to the overall workload of lab personnel. Moreover, the frequency of these changes can vary depending on the specific application and the types of solvents being used, making it a variable and unpredictable aspect of pump maintenance.

To mitigate these challenges, some labs have adopted advanced filtration systems or automated water change mechanisms, which can reduce the frequency and mess associated with manual water changes. However, these solutions often come with additional costs and complexities, which may not be feasible for all labs. Thus, the need for frequent water changes remains a notable disadvantage of using circulating water vacuum pumps, especially in vertical configurations.

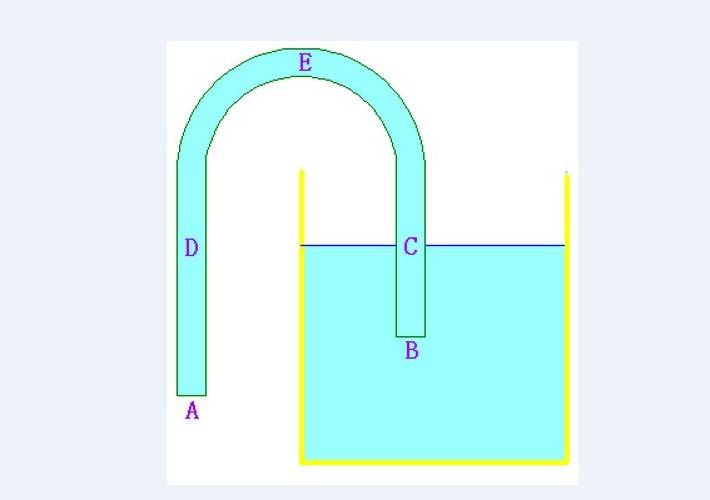

Noise and Back Siphoning

The circulating water vacuum pump, while indispensable in synthesis labs, is not without its drawbacks. One of the most notable issues is the significant noise it generates. This noise can be disruptive, making it difficult for researchers to concentrate, especially in quiet environments where precision is paramount. The decibel levels produced by these pumps can be substantial, often exceeding what is considered comfortable or acceptable in a laboratory setting.

In addition to noise, the pump is susceptible to back siphoning, a phenomenon that can occur during power outages or due to improper use. Back siphoning happens when the vacuum pressure is lost, causing liquids to flow backward through the pump. This can lead to contamination of the pump and the system it is connected to, necessitating extensive cleaning and potential downtime for the lab. The risk of back siphoning is particularly high in setups where volatile solvents are used, as these can pose additional safety hazards if they are inadvertently drawn back into the system.

To mitigate these issues, several strategies can be employed. For noise reduction, using soundproof enclosures or placing the pump in a separate room can help. Additionally, regular maintenance and ensuring that the pump is used according to manufacturer guidelines can minimize the risk of back siphoning. However, for labs where noise and back siphoning are persistent concerns, exploring alternative solutions, such as diaphragm vacuum pumps, may be warranted. Diaphragm pumps, known for their quiet operation and resistance to back siphoning, offer a viable alternative that can significantly enhance the working environment and safety protocols in synthesis labs.

Lack of Exhaust Gas Absorption

The circulating water vacuum pump's inability to absorb exhaust gases presents significant health and safety concerns, particularly when dealing with volatile solvents. These solvents, which are commonly used in synthesis labs, can release harmful vapors that pose risks to lab personnel and the environment. The lack of an integrated exhaust gas absorption system means that these vapors are often released directly into the lab atmosphere, increasing the risk of inhalation exposure and potential contamination.

Moreover, the absence of an effective gas absorption mechanism can lead to the accumulation of hazardous fumes, which can compromise the quality of experiments and affect the accuracy of results. This issue is compounded by the fact that many labs operate in confined spaces, where air circulation may be limited, further exacerbating the problem.

To mitigate these risks, labs often resort to supplementary measures such as installing fume hoods or using alternative pumps that are equipped with gas absorption capabilities. However, these solutions can be costly and may not always be feasible, especially in resource-constrained environments.

Alternative Solutions: Diaphragm Pumps

Chemical Resistance and Vapor Resistance

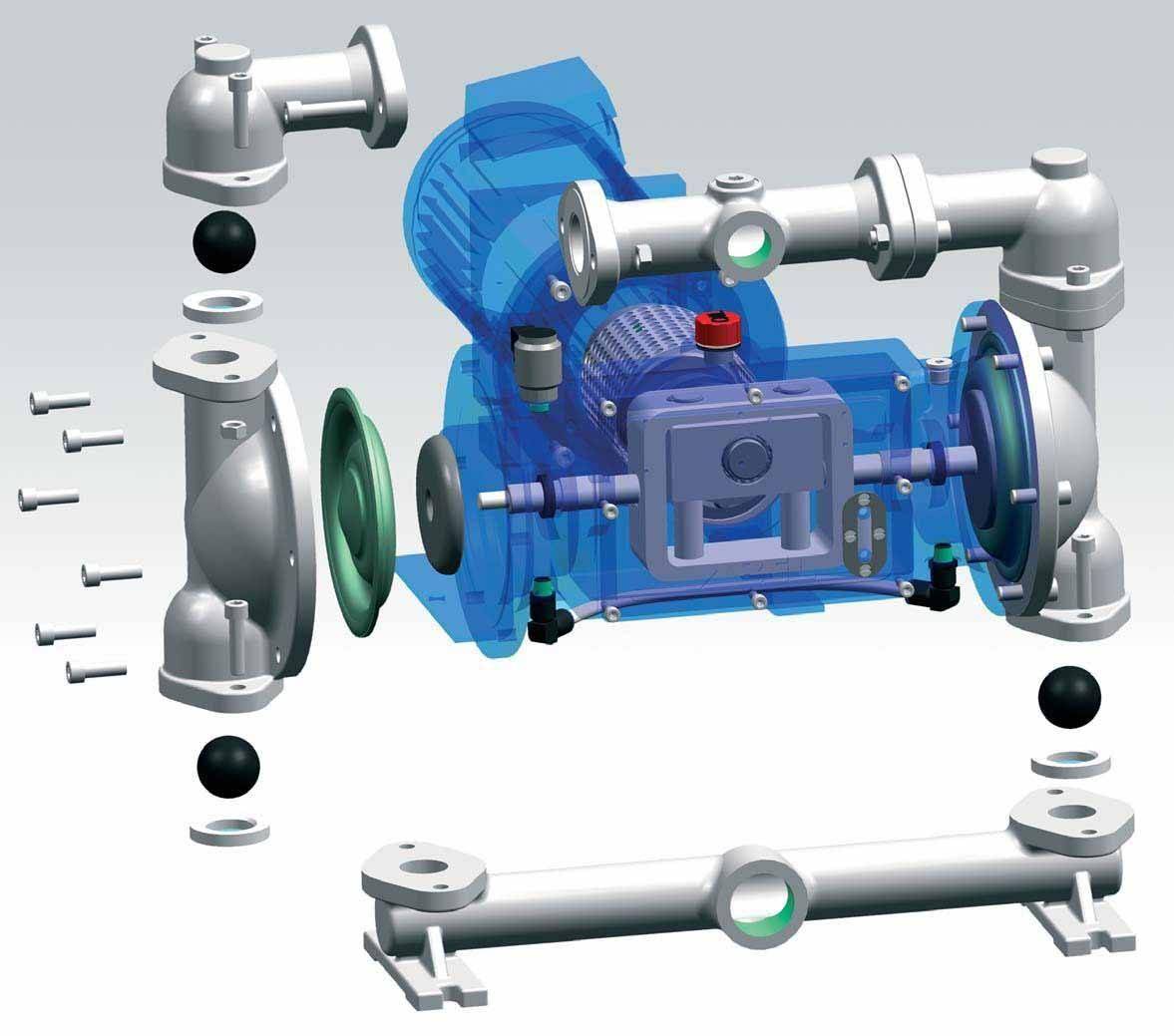

Diaphragm pumps are engineered with materials that exhibit exceptional chemical resistance, enabling them to withstand a wide range of pumped media without degradation. These materials are chosen not only for their ability to resist chemical attack but also for their vapor resistance, which is crucial in environments where volatile solvents are commonly used.

In contrast to circulating water vacuum pumps, which require frequent water changes and can suffer from back siphoning, diaphragm pumps offer a more stable and reliable solution. Their design ensures that they remain unaffected by the corrosive and volatile nature of many laboratory fluids, making them a preferred choice for tasks that demand both chemical and vapor resistance.

The superior resistance of diaphragm pumps to pumped media is further enhanced by their maintenance-free operation. Unlike traditional pumps that need regular maintenance and are susceptible to noise and vibration, diaphragm pumps provide quiet and stable performance, contributing to a safer and more efficient laboratory environment. This makes them an ideal alternative for synthesis labs where the integrity of the equipment and the safety of the environment are paramount.

Maintenance-Free Operation

Unlike traditional circulating water vacuum pumps, diaphragm pumps operate without the need for water or oil. This unique feature eliminates the hassle of frequent water changes, which is a common maintenance task for many lab pumps. Moreover, these pumps are entirely maintenance-free, reducing the time and effort required for upkeep.

One of the standout advantages of diaphragm pumps is their ability to prevent back siphoning. This is particularly crucial in lab settings where power outages or equipment misuse can lead to hazardous situations. By eliminating back siphoning, diaphragm pumps ensure a safer and more controlled environment, minimizing risks associated with fluid contamination and equipment damage.

In summary, the maintenance-free operation of diaphragm pumps not only simplifies lab management but also enhances safety by preventing back siphoning and reducing the need for routine maintenance.

Quiet and Stable Performance

Diaphragm pumps distinguish themselves with their exceptional vacuum stability, operating at a whisper-quiet level and producing minimal vibration. This combination of features makes them an ideal choice for laboratories where noise and vibration can be disruptive. Unlike traditional circulating water vacuum pumps, which can be noisy and prone to back siphoning, diaphragm pumps offer a more serene and reliable operation. This quiet performance not only enhances the working environment but also ensures that delicate experiments are not compromised by external disturbances. Additionally, the low vibration levels contribute to the longevity of both the pump and the equipment it supports, reducing the need for frequent maintenance and downtime.

Solvent Recovery

The inclusion of a secondary solvent recovery device ensures nearly 100% recovery of solvents, contributing significantly to a safer lab environment. This device is particularly effective with solvents like alcohol, which can be recovered and reused multiple times, although potential contamination must be monitored. For instance, alcohol can become contaminated depending on the sample, especially if the contaminants share the same boiling range as the solvent. Techniques such as fractional distillation or the use of molecular sieves can help maintain the purity of the recovered alcohol, ensuring it remains above 90% concentration.

A rotary evaporator is particularly beneficial for this process, offering faster recovery speeds while minimizing solvent degradation. The recovered solvent is collected in a separate receiving flask, facilitating easy reuse or storage for future applications. This method not only conserves resources but also reduces waste, aligning with modern laboratory sustainability practices.

Related Products

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

- Vacuum Cold Trap Direct Cold Trap Chiller

- Laboratory Rotary Vane Vacuum Pump for Lab Use

Related Articles

- Choosing the Right Rotary Vacuum Evaporator for Your Lab

- Discover The Benefits of Using A Rotary Evaporator

- Step-by-Step Guide to Operating a Short Path Distillation Apparatus

- The Importance of Water Distillation in the Laboratory: Ensuring Purity and Quality for Accurate Results

- How to Choose Laboratory Vacuum Pumps for Maximum Efficiency and Cost Savings