Selecting the right vacuum pump for your lab isn’t just about specs—it’s about aligning performance, total cost, and workflow demands. This guide helps you navigate the trade-offs between oil-sealed and oil-free technologies, avoid common pitfalls, and future-proof your investment.

Strategic Pump Selection for Lab Efficiency

Decoding Your Lab’s Vacuum Requirements: Beyond Basic Specifications

Before comparing pump models, define your lab’s actual needs:

- Pressure Range: Analytical instruments (e.g., GC-MS) often require ultra-low pressures (~10⁻³ mbar), while filtration tasks may only need moderate vacuum (~100 mbar).

- Gas Compatibility: Will the pump handle corrosive vapors, particulates, or solvents? Oil-free pumps avoid contamination but may degrade with aggressive chemicals.

- Usage Patterns: Intermittent vs. continuous operation impacts lifespan. For example, rotary vane pumps under heavy use may need annual overhauls, while diaphragm pumps can last 5+ years with minimal maintenance.

Key Question: Have you mapped your lab’s peak demand periods to avoid under- or over-specifying pump capacity?

Total Cost of Ownership Deep Dive: Upfront Price vs. Lifetime Expenses

A $2,000 oil-sealed pump can cost $5,000+ over a decade due to:

- Maintenance: Oil changes (3–4x/year), filter replacements, and disposal fees for contaminated oil.

- Downtime: Service interruptions for repairs or oil changes, which can halt critical workflows.

- Energy Use: Older rotary vane designs consume ~30% more power than modern oil-free equivalents.

In contrast, oil-free scroll or diaphragm pumps offer:

- Lower Lifetime Costs: No oil changes and service intervals up to 15,000 hours (~7 years at 20 hrs/week).

- Contamination Prevention: Critical for sensitive applications like pharmaceutical QC or trace analysis.

Data Insight: Labs using oil-free pumps report ~40% lower annual operating costs after the 3-year mark.

Application-Driven Pump Matchmaking

Case Study Snapshots: Real-World Pump Selection in Diverse Labs

- Pharmaceutical QC Lab: Switched from rotary vane to oil-free diaphragm pumps after hydrocarbon backstreaming skewed GC-MS results. Saved $12,000 in 5 years on maintenance and retesting.

- Environmental Testing Lab: Chose a hybrid (scroll + diaphragm) pump for corrosive gas sampling. Achieved 90% uptime over 4 years with quarterly filter changes.

Pro Tip: Match pump technology to your critical tasks—don’t assume "high-end" always means better fit.

Avoiding Critical Pitfalls: Contamination, Downtime, and Underperformance

- Oil Contamination: Hydrocarbon backstreaming from oil-sealed pumps can ruin sensitive samples (e.g., in mass spectrometry).

- Overheating: Rotary vanes in continuous duty may fail prematurely without cooling breaks.

- Wrong Scale: A pump sized for large-volume distillation will waste energy on small-scale filtrations.

Red Flag: If your supplier can’t explain how the pump handles your specific gases, keep looking.

Future-Proofing Your Investment

Leveraging Hybrid Technologies and Smart Monitoring

- Hybrid Pumps: Combine oil-free diaphragms (for clean stages) with scrolls (for higher throughput), balancing purity and speed.

- IoT Sensors: Track vibration, temperature, and pressure to predict failures before they disrupt workflows.

Example: A biotech lab reduced unplanned downtime by 60% after adding real-time pump diagnostics.

Customization and Scalability for Evolving Workflows

- Modular Designs: Some pumps allow adding stages or ports as needs change (e.g., expanding from solvent evaporation to freeze-drying).

- Retrofit Kits: Upgrade older pumps with energy-efficient motors or filtration add-ons.

Planning Tip: Ask vendors about upgrade paths—not just today’s specs.

Next Steps: Optimize Your Lab’s Vacuum Efficiency

Choosing the right vacuum pump requires weighing technical needs against hidden costs and future flexibility. For labs prioritizing clean, low-maintenance operation, oil-free technologies often deliver superior long-term value.

Ready to streamline your lab’s vacuum systems? Explore KINTEK’s range of reliable, cost-effective vacuum pumps and consumables—engineered to keep your workflows running smoothly.

[Contact KINTEK today for a personalized equipment assessment.]

Related Products

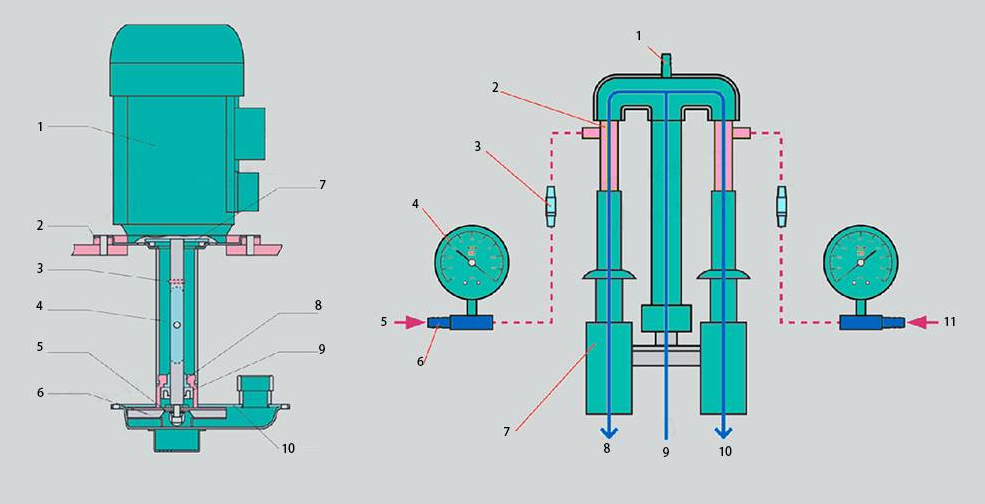

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

- lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

Related Articles

- Common Mistakes to Avoid When Using a Rotary Vacuum Evaporator

- Boost Your Efficiency Why A Rotary Evaporator Is Better

- A Comprehensive Guide to Understanding Rotary Evaporator Chillers

- A Step-by-Step Guide to Using a Rotary Vacuum Evaporator for Solvent Removal

- Choosing the Right Rotary Vacuum Evaporator for Your Lab