Yes, absolutely. Sieving is a fundamental mechanical process designed specifically for separating mixtures composed of particles of different sizes. It operates on the simple principle of using a mesh or screen as a physical barrier. Smaller particles pass through the openings, while larger particles are retained.

The core function of sieving is to exploit differences in physical size to segregate components of a solid mixture. The effectiveness of this technique depends entirely on selecting a sieve with a mesh size that is smaller than the particles you wish to retain and larger than those you wish to pass through.

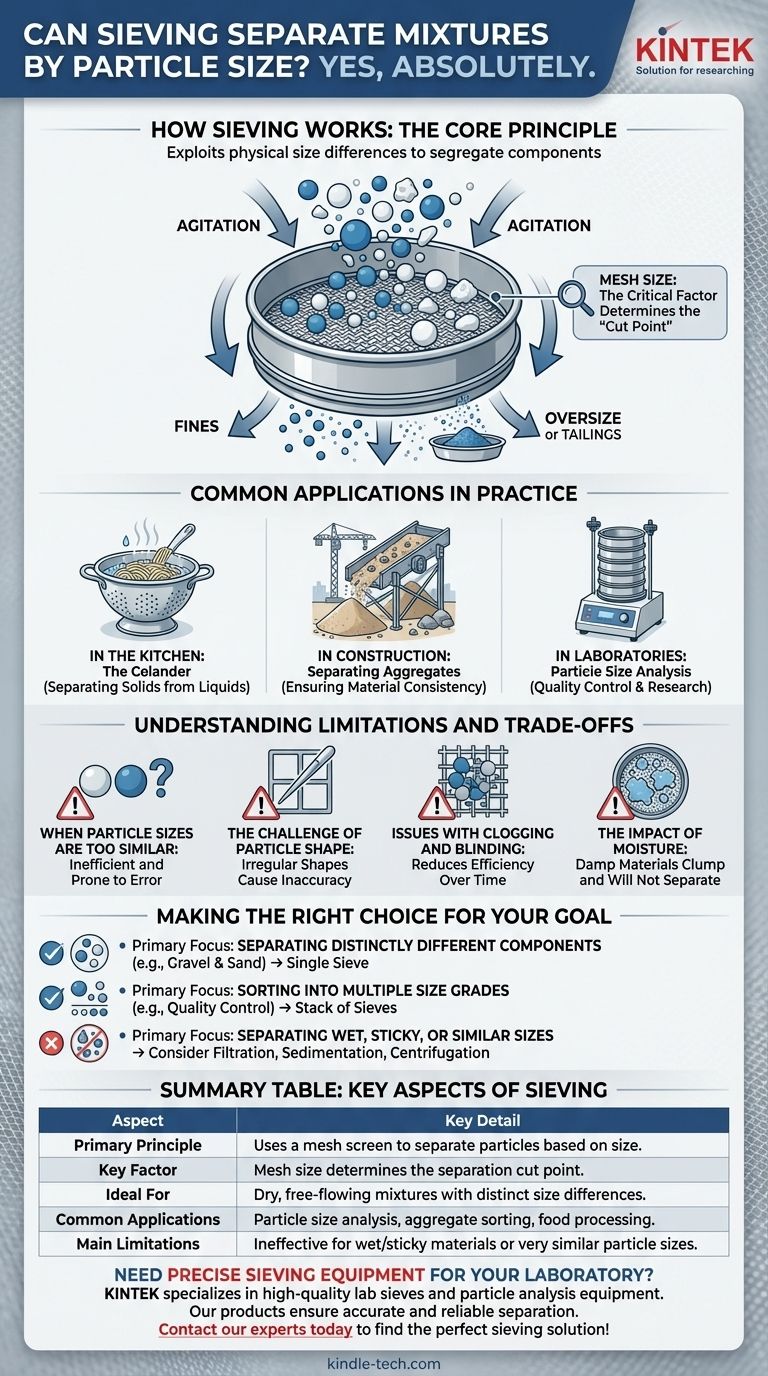

How Sieving Works: The Core Principle

Sieving is one of the oldest and most intuitive methods of separation. Its effectiveness is rooted in the physical properties of the mixture's components and the tool used to separate them.

The Sieve: A Selective Barrier

The heart of the process is the sieve, which is simply a screen containing a grid of uniform openings or pores. This screen acts as a selective barrier.

Any particle smaller than the openings in the mesh can fall through under the influence of gravity or agitation. Any particle larger than the openings will be held back.

The Process: Agitation and Separation

To separate a mixture, it is placed on top of the sieve. The sieve is then shaken or agitated.

This movement ensures that all particles come into contact with the screen, giving the smaller particles the opportunity to find an opening and pass through. The material that passes through is called the "fines," while the material retained on the sieve is the "oversize" or "tailings."

Key Factor: Mesh Size

The most critical parameter in sieving is the mesh size, which defines the dimensions of the openings in the screen.

Mesh size determines the "cut point"—the size that separates the fine particles from the coarse ones. For precise scientific or industrial applications, sieves are often stacked in a "sieve stack" with progressively smaller mesh sizes from top to bottom, allowing the mixture to be sorted into multiple size grades simultaneously.

Common Applications in Practice

The principle of sieving is applied across countless fields, from everyday household tasks to large-scale industrial processes.

In the Kitchen: The Colander

A kitchen colander is a perfect example of a sieve. It is used to separate solid pasta from liquid water. The holes are large enough for water to pass through easily but small enough to retain the pasta. Sifting flour to remove lumps is another common application.

In Construction: Separating Aggregates

On construction sites, large screens are used to separate sand, gravel, and larger rocks from one another. This ensures that materials like concrete and asphalt have components of the correct size for optimal strength and consistency.

In Laboratories: Particle Size Analysis

In scientific and quality control labs, highly precise sieves are used to determine the particle size distribution of a sample. This is critical in industries like pharmaceuticals, food production, and metallurgy, where particle size can dramatically affect a product's properties.

Understanding the Limitations and Trade-offs

While powerful, sieving is not a universal solution and has important limitations that determine its suitability for a given task.

When Particle Sizes Are Too Similar

Sieving is most effective when there is a significant difference in the size of the components you wish to separate. If the particles are very close in size, the process becomes inefficient and prone to error, as particles may or may not pass through the mesh depending on their orientation.

The Challenge of Particle Shape

Standard sieves work best with spherical or granular particles. Long, thin, or irregularly shaped particles can pose a problem. A needle-like particle might pass through a mesh end-on, even if its length is much greater than the mesh opening, leading to inaccurate separation.

Issues with Clogging and Blinding

Fine powders or particles that are very close to the mesh size can get stuck in the openings, a phenomenon known as blinding or clogging. This reduces the effective area of the sieve and dramatically lowers its efficiency over time.

The Impact of Moisture

Sieving is primarily intended for dry, free-flowing materials. If a mixture is damp or contains moisture, particles can clump together due to surface tension. These clumps will behave like larger particles and will not be separated correctly based on their individual sizes.

Making the Right Choice for Your Goal

To apply this technique effectively, you must align the method with your specific objective.

- If your primary focus is separating distinctly different components (like gravel from sand): A single sieve with an appropriately chosen mesh size is a fast and highly effective solution.

- If your primary focus is sorting a material into multiple size grades (like for quality control): A stack of sieves with progressively smaller mesh sizes is the standard and correct approach.

- If your primary focus is separating components that are wet, sticky, or very similar in size: Sieving is likely not the right method, and you should consider alternatives like filtration, sedimentation, or centrifugation.

Ultimately, sieving is a powerful and direct method for separating mixtures based on the fundamental property of particle size.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Principle | Uses a mesh screen to separate particles based on size. |

| Key Factor | Mesh size determines the separation cut point. |

| Ideal For | Dry, free-flowing mixtures with distinct size differences. |

| Common Applications | Particle size analysis, aggregate sorting, food processing. |

| Main Limitations | Ineffective for wet/sticky materials or very similar particle sizes. |

Need precise sieving equipment for your laboratory? KINTEK specializes in high-quality lab sieves and particle analysis equipment. Our products ensure accurate and reliable separation for your specific application, from quality control to R&D. Contact our experts today to find the perfect sieving solution for your needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the importance of sieve analysis test? Unlock Material Performance & Quality Control

- What is sieve analysis in construction? Ensure Material Quality & Project Success

- What is the significance of using a standard sieve before the sintering of CaF2 nanopowders? Ensure Optical Clarity

- Why is it necessary to use a laboratory sieve after the synthesis and calcination of a photocatalyst? Ensure Accuracy

- Why must ultra-fine ceramic powders be processed with a standard sieve? Key to Defect-Free Sintering

- Why is it necessary to perform sieving with standard grading sieves before conducting thermal analysis on flax straw?

- Why is a 150-mesh standard sieve essential for the preparation of honeycomb ceramic Mn-Ce/Al2O3 catalysts?

- Why is the sieve test important? The Key to Quality Control and Product Consistency