At its core, a heating element is manufactured by embedding a carefully chosen resistance wire within a compressed ceramic insulator, which is then sealed inside a protective metal casing. This three-part structure is fundamental to safely and efficiently converting electricity into heat for countless applications, from household appliances to industrial processes.

The manufacturing of a heating element is a precise balancing act. The goal is to maximize heat generation and transfer while ensuring electrical safety and mechanical durability against the destructive forces of high temperatures and repeated thermal cycling.

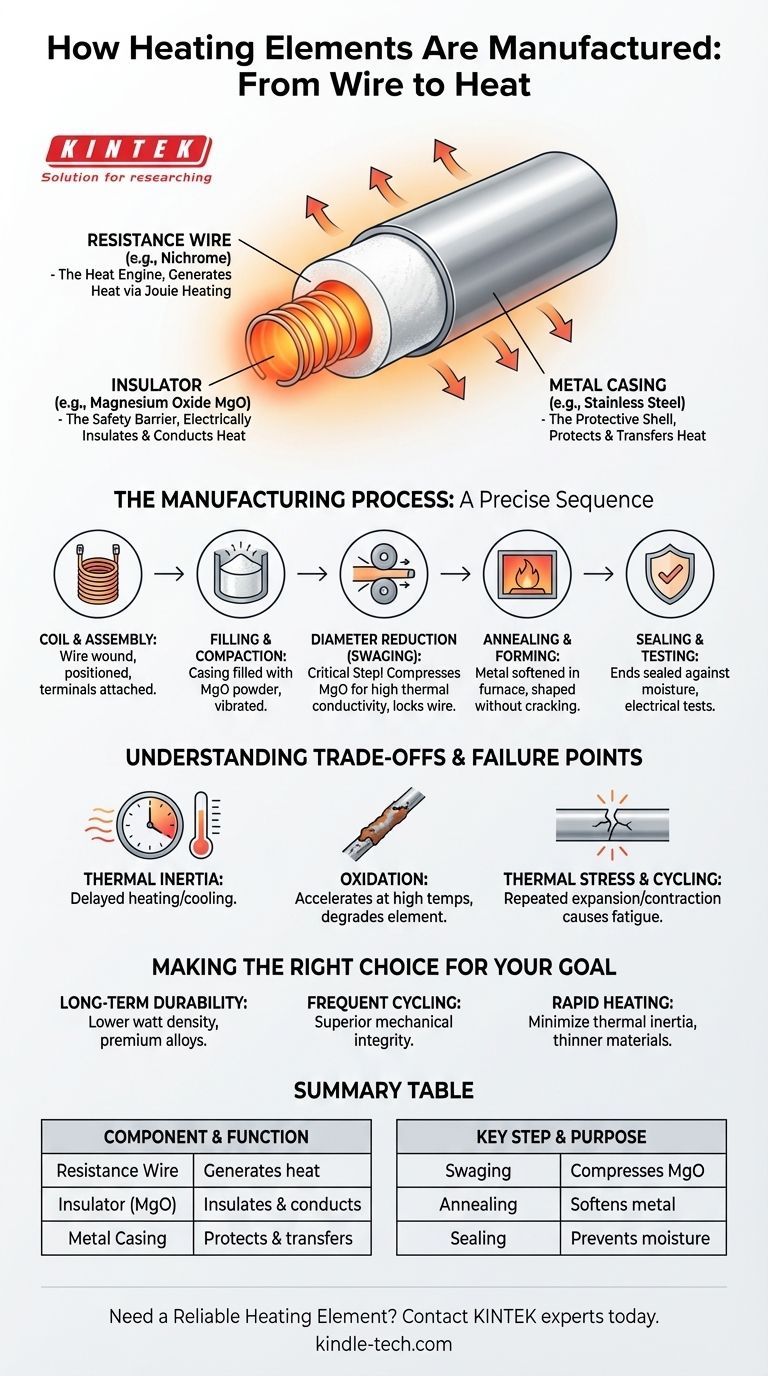

The Anatomy of a Heating Element

Every component in a heating element is chosen to perform a specific function. The final product's performance and lifespan are a direct result of how well these parts work together.

The Resistance Wire: The Heat Engine

The heart of the element is a wire made from a material with high electrical resistance. When electric current is forced through it, the resistance causes the wire to heat up—a principle known as Joule heating.

The most common material is a Nichrome alloy (nickel and chromium) because it forms a stable, protective layer of chromium oxide on its surface when heated. This layer prevents the wire from oxidizing further and burning out quickly.

The Insulator: The Safety Barrier

Surrounding the resistance wire is a layer of ceramic insulating material, typically Magnesium Oxide (MgO) powder. This material is a superb electrical insulator but a good thermal conductor.

Its critical job is twofold: it prevents the live electrical wire from touching the outer metal casing, which would cause a dangerous short circuit. At the same time, it efficiently transfers the heat generated by the wire outward to the casing.

The Metal Casing: The Protective Shell

The outer layer is a metal tube or sheath, often made of stainless steel, Incoloy, or copper, depending on the application.

This casing provides structural integrity, protects the fragile internal components from moisture and physical damage, and serves as the primary surface for transferring heat to the surrounding environment—be it air, water, or a solid plate.

The Manufacturing Process: From Wire to Element

The assembly of these components is a multi-stage process designed to create a solid, durable, and efficient unit.

1. Coil and Assembly

First, the resistance wire is wound into a precise coil. This coil is then carefully positioned inside the hollow metal casing, and terminals are attached to its ends.

2. Filling and Compaction

The space between the coiled wire and the inner wall of the casing is filled with the fine Magnesium Oxide insulating powder. The entire assembly is then vibrated to ensure the powder is distributed evenly, with no voids.

3. Diameter Reduction (Swaging)

This is the most critical step. The filled tube is passed through rollers or a swaging machine that reduces its overall diameter. This process heavily compresses the MgO powder, transforming it into a dense, solid mass.

This compaction is vital because it dramatically improves the insulation's thermal conductivity, allowing heat to escape the wire quickly. It also locks the coiled wire firmly in place.

4. Annealing and Forming

The swaging process makes the metal hard and brittle. The element is then heated in a furnace (annealed) to soften the metal, allowing it to be bent and formed into its final required shape without cracking.

5. Sealing and Testing

Finally, the ends of the element are sealed to prevent the highly hygroscopic (water-absorbing) MgO powder from drawing in moisture from the air, which would destroy its insulating properties. The finished element undergoes rigorous testing for electrical resistance and insulation integrity.

Understanding the Trade-offs and Failure Points

The design and manufacturing process must account for inherent challenges that dictate the element's lifespan.

Thermal Inertia

The very layers that make an element safe—the insulation and the casing—also create a delay. It takes time for heat to travel through them, meaning the element doesn't heat up or cool down instantly. This is known as thermal inertia.

Oxidation at High Temperatures

Even with protective alloys like Nichrome, operating at extreme temperatures accelerates oxidation. The "hottest point" on the element will degrade the fastest, making uniform heat distribution a key design goal.

Thermal Stress and Cycling

Every time the element turns on and off, it expands and contracts. This repeated thermal stress can eventually cause mechanical fatigue, leading to cracks in the wire or casing. Elements used in intermittent operations face a much harder life than those running continuously.

Making the Right Choice for Your Goal

The manufacturing approach is tailored to the element's intended use. Understanding the final application is key to designing for longevity and performance.

- If your primary focus is long-term durability: The design must use premium alloys and operate at a lower watt density (spreading heat over a larger surface area) to minimize the peak temperature and slow oxidation.

- If your primary focus is frequent on/off cycling: The element needs superior mechanical integrity to withstand the constant expansion and contraction caused by thermal stress.

- If your primary focus is rapid heating: The design must minimize thermal inertia, which often means using thinner materials and more compact insulation, sometimes trading maximum lifespan for speed.

Ultimately, manufacturing a heating element is an exercise in managing heat, ensuring safety, and fighting the inevitable effects of temperature over time.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Resistance Wire | Nichrome Alloy | Generates heat via electrical resistance (Joule heating) |

| Insulator | Magnesium Oxide (MgO) | Electrically insulates the wire while conducting heat |

| Metal Casing | Stainless Steel, Incoloy, Copper | Protects internal parts and transfers heat to the environment |

| Key Manufacturing Step | Purpose |

|---|---|

| Coil and Assembly | Positions the resistance wire inside the casing |

| Filling and Compaction | Evenly distributes MgO insulating powder |

| Diameter Reduction (Swaging) | Compresses MgO to improve thermal conductivity and lock the wire in place |

| Annealing and Forming | Softens the metal for shaping without cracking |

| Sealing and Testing | Prevents moisture absorption and ensures electrical safety |

Need a Reliable Heating Element for Your Laboratory Equipment?

The precise manufacturing process described is what ensures the performance and safety of your lab instruments. At KINTEK, we specialize in supplying high-quality laboratory heating elements and consumables designed for durability and precise temperature control. Whether your priority is long-term durability, frequent cycling, or rapid heating, our solutions are engineered to meet the rigorous demands of your research and processes.

Let us help you enhance your lab's efficiency and reliability. Contact our experts today to discuss your specific heating needs!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- Why are temperature controllers and thermocouples critical for magnesium powder? Master Precision Thermal Control

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- How effective is electrical resistance heating? It's 100% efficient at the point of use.

- How do resistive heating elements work? Unlock the Science of Efficient Heat Generation

- Why is tungsten so heat resistant? Unlocking Its Atomic Secrets for Extreme Temperatures

- Why does heater wire have high resistance? To Efficiently Convert Electricity into Heat

- What is the thermal expansion coefficient of molybdenum disilicide? Understanding its role in high-temperature design