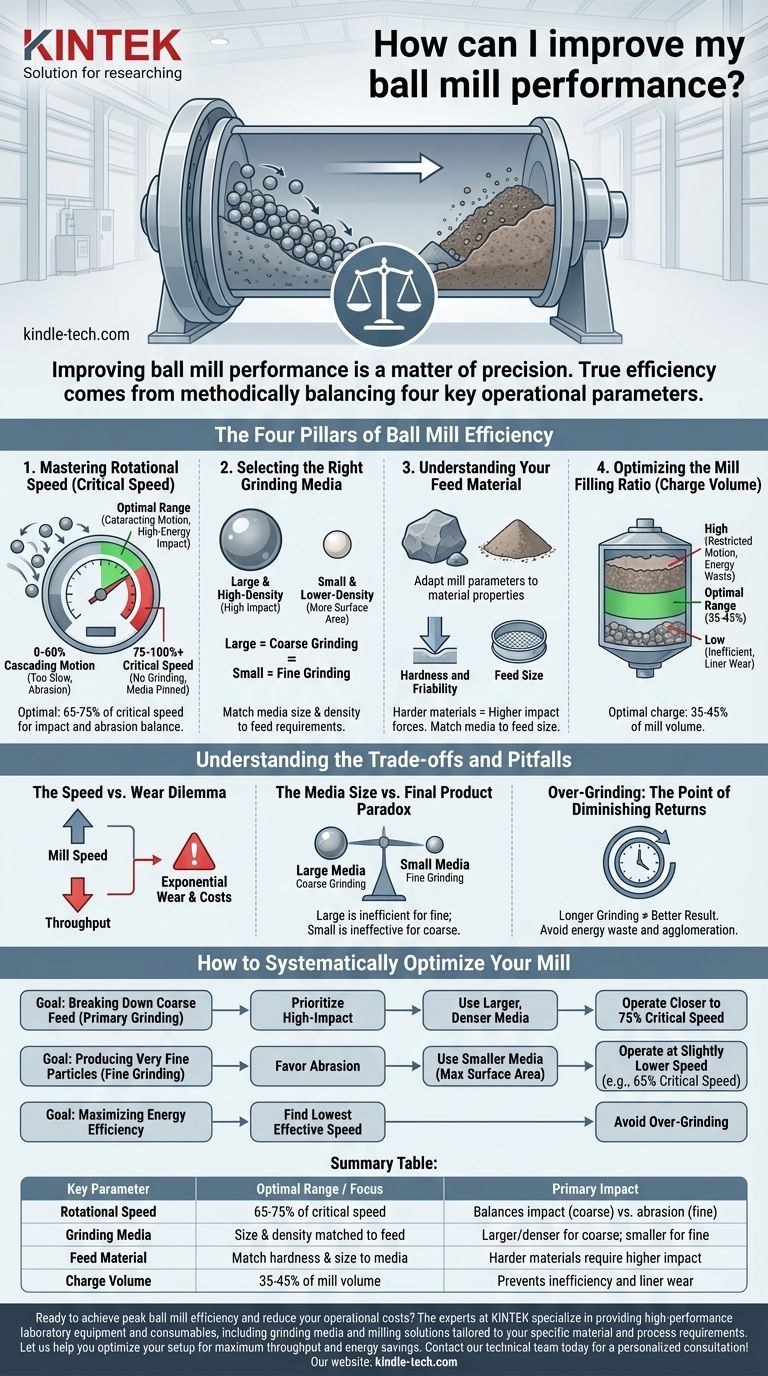

Improving ball mill performance is a matter of precision. True efficiency comes from methodically balancing four key operational parameters: the rotational speed of the mill, the characteristics of your grinding media, the properties of the material being ground, and the volume of the charge filling the mill.

The core principle of ball mill optimization is not about maximizing any single variable, but about achieving the ideal balance between impact (for coarse grinding) and abrasion (for fine grinding) to match your specific material and final product requirements.

The Four Pillars of Ball Mill Efficiency

Optimizing a ball mill requires understanding how its core components interact. Each variable directly influences the grinding mechanism and overall energy consumption.

1. Mastering Rotational Speed (The "Critical Speed" Concept)

The speed of the mill is arguably the most influential factor. It's best understood in relation to "critical speed," which is the theoretical speed at which the grinding media would simply be pinned to the mill's inner wall by centrifugal force.

Operating at this speed (or above) results in zero grinding.

Effective grinding occurs within a specific percentage of this critical speed. Too slow, and the media just tumbles down the surface of the charge in a cascading motion, which favors abrasion but lacks the impact needed to break larger particles.

The optimal range is typically 65-75% of critical speed. This creates a cataracting motion, where the media is lifted nearly to the top of the mill and then falls onto the material, creating the high-energy impacts necessary for efficient particle size reduction.

2. Selecting the Right Grinding Media

The grinding media—the balls themselves—are the instruments of size reduction. Their characteristics are critical.

Media Size dictates the energy of each impact. Larger, heavier balls create powerful impacts needed to break large feed particles. Smaller balls create more frequent, lower-energy impacts and provide greater surface area, which is ideal for fine grinding.

Media Density also plays a key role. High-density media like forged steel delivers significantly more impact energy than lower-density media like ceramics, making it suitable for hard materials.

3. Understanding Your Feed Material

The material you are grinding dictates the entire setup. You must adapt the mill's parameters to the material's properties, not the other way around.

Hardness and Friability determine the amount of energy required for breakage. Harder, less friable materials require higher impact forces, meaning denser media and a speed closer to the top of the optimal range.

Feed Size must be matched to your grinding media. As a rule of thumb, the largest media should be appropriately sized to effectively fracture the largest particles in your feed. If the media is too small, it will be ineffective.

4. Optimizing the Mill Filling Ratio (The "Charge Volume")

The charge volume is the total percentage of the mill's internal volume occupied by the grinding media.

A low charge level (e.g., below 30%) reduces the number of grinding events, leading to inefficiency and accelerated wear on the mill liners, which are struck directly by media.

An excessively high charge level (e.g., above 45%) restricts the motion of the media. This prevents the balls from being lifted properly, dampens the cataracting action, and wastes significant energy. The optimal charge is typically between 35-45%.

Understanding the Trade-offs and Pitfalls

Tuning a ball mill is a balancing act. Improving one metric can often come at the expense of another.

The Speed vs. Wear Dilemma

Increasing mill speed towards the upper end of the optimal range can increase throughput. However, this comes at a significant cost. Wear on both the grinding media and the mill liners increases exponentially with speed, driving up operational and maintenance costs.

The Media Size vs. Final Product Paradox

Using large media is excellent for the initial stages of grinding coarse material. However, these large balls are highly inefficient at producing very fine particles. Conversely, a charge of small media is perfect for fine grinding but will be completely ineffective against a coarse feed.

Over-Grinding: The Point of Diminishing Returns

Grinding material for longer than necessary is a common and costly mistake. It consumes enormous amounts of energy with little to no additional size reduction. In some cases, it can even be detrimental, leading to particle agglomeration or unwanted changes in material properties.

How to Systematically Optimize Your Mill

Use your specific goal to guide your adjustments. Start with one variable, measure the result, and iterate methodically.

- If your primary focus is breaking down coarse feed (Primary Grinding): Prioritize high-impact forces by using larger, denser media and operating closer to 75% of critical speed.

- If your primary focus is producing very fine particles (Fine Grinding): Favor abrasion by using smaller media to maximize surface area and operating at a slightly lower speed (e.g., 65% of critical speed).

- If your primary focus is maximizing energy efficiency: Find the lowest speed that still achieves your target particle size within the required time and be vigilant about avoiding over-grinding.

By methodically adjusting these variables, you can transform your ball mill from a brute-force tool into a highly precise and efficient processing instrument.

Summary Table:

| Key Parameter | Optimal Range / Focus | Primary Impact |

|---|---|---|

| Rotational Speed | 65-75% of critical speed | Balances impact (coarse grinding) vs. abrasion (fine grinding) |

| Grinding Media | Size & density matched to feed | Larger/denser media for coarse feed; smaller media for fine grinding |

| Feed Material | Match hardness & size to media | Harder materials require higher impact forces |

| Charge Volume | 35-45% of mill volume | Prevents inefficiency and excessive liner wear |

Ready to achieve peak ball mill efficiency and reduce your operational costs?

The experts at KINTEK specialize in providing high-performance laboratory equipment and consumables, including grinding media and milling solutions tailored to your specific material and process requirements. Let us help you optimize your setup for maximum throughput and energy savings.

Contact our technical team today for a personalized consultation!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Twin Screw Extruder Plastic Granulation Machine

People Also Ask

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability