To improve the efficiency of a ball mill, you must systematically optimize the relationship between its rotational speed, the characteristics of the grinding media (the balls), and the volume of material being processed. These three variables directly control the grinding action inside the mill, determining whether energy is used effectively for particle size reduction or wasted on excess heat, noise, and equipment wear.

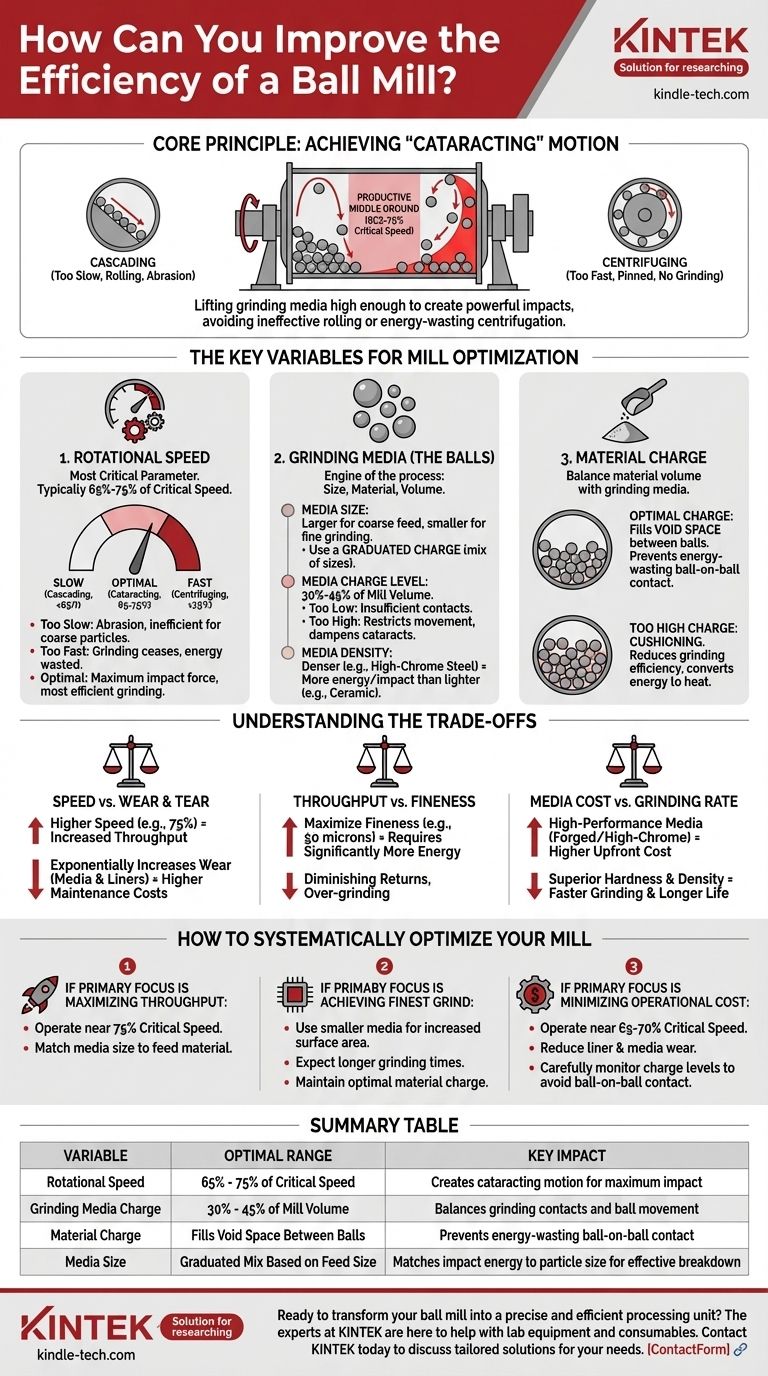

The core principle of ball mill efficiency is achieving a state of "cataracting" motion, where the grinding media are lifted high enough to fall and create powerful impacts, without being pinned to the mill wall by centrifugal force. This is the productive middle ground between ineffective rolling and energy-wasting centrifugation.

The Key Variables for Mill Optimization

True efficiency isn't about running the mill faster or longer; it's about creating the ideal internal environment for comminution (particle size reduction). This requires a careful balancing of several interconnected factors.

1. Rotational Speed

The speed of the mill is arguably the most critical parameter. It is typically defined as a percentage of the "critical speed"—the theoretical speed at which the outermost layer of balls would centrifuge and cling to the mill liner.

- Too Slow (Cascading): Below 65% of critical speed, the balls tend to tumble and roll down the face of the charge. This action is dominated by abrasion and is inefficient for breaking down coarser particles.

- Too Fast (Centrifuging): Approaching or exceeding the critical speed causes the balls to be pinned against the mill wall. Grinding action ceases entirely, and all energy is wasted.

- Optimal (Cataracting): Typically between 65% and 75% of critical speed, the balls are lifted on the rising side of the mill and fall freely onto the charge. This creates the maximum impact force, leading to the most efficient grinding.

2. Grinding Media (The Balls)

The balls are the engine of the grinding process. Their size, material, and the total volume they occupy are crucial for efficiency.

- Media Size: Larger balls are necessary for breaking down large feed particles due to their higher impact energy. Smaller balls provide more surface area and are better for fine grinding of already smaller particles. An optimal setup often uses a graduated charge with a mix of sizes.

- Media Charge Level: This is the volume of the mill filled by the balls, typically between 30% and 45%. Too low a charge results in insufficient grinding contacts. Too high a charge can restrict the movement of the material and the balls, dampening the cataracting motion.

- Media Density: Denser media, such as high-chromium steel, delivers more energy per impact than lighter media like ceramic. The choice depends on the hardness of the material being ground and the desired level of contamination.

3. Material Charge

The amount of material fed into the mill must be balanced with the grinding media.

- Charge Volume: The optimal material charge fills the void space between the balls. If the material level is too low, the balls will strike each other and the mill liner, wasting energy and causing rapid wear.

- Charge Level Too High: If the material level is too high, it will cushion the impacts of the falling balls, drastically reducing grinding efficiency and converting energy into heat.

Understanding the Trade-offs

Optimizing a ball mill is not a one-size-fits-all process. Improving one metric often comes at the expense of another, and understanding these compromises is key to effective management.

Speed vs. Wear and Tear

Operating at the higher end of the optimal speed range (e.g., 75% of critical speed) will generally increase throughput. However, it also exponentially increases the wear rate of both the grinding media and the mill's internal liners, leading to higher maintenance costs and more frequent downtime.

Throughput vs. Fineness

Achieving a very fine particle size requires significantly more energy and time. The relationship is not linear; reducing particle size from 100 microns to 50 microns takes far more energy than reducing it from 200 to 150. Pushing for maximum fineness can lead to diminishing returns where most energy is spent over-grinding particles that are already small enough.

Media Cost vs. Grinding Rate

High-performance media (forged steel, high-chrome steel) is more expensive upfront but offers superior hardness, density, and wear resistance. This translates to faster grinding and longer life. For less demanding applications, cheaper cast iron or ceramic media may be sufficient, but they will wear faster and grind less effectively.

How to Systematically Optimize Your Mill

Your approach should be guided by your primary operational goal. Define what "efficiency" means for your specific process and adjust the key variables accordingly.

- If your primary focus is maximizing throughput: Operate near the higher end of the optimal speed range (around 75% critical speed) and ensure your media size is correctly matched to break down your feed material effectively.

- If your primary focus is achieving the finest grind: Consider using smaller grinding media to increase surface area contact and be prepared for longer grinding times. Maintain an optimal material charge to avoid cushioning effects.

- If your primary focus is minimizing operational cost: Operate at a slightly lower speed (around 65-70% critical speed) to significantly reduce liner and media wear. Carefully monitor your media and material charge levels to ensure no energy is wasted on mill-on-mill contact.

By methodically adjusting and measuring these core parameters, you can transform your ball mill from a brute-force tool into a precise and highly efficient processing unit.

Summary Table:

| Variable | Optimal Range | Key Impact |

|---|---|---|

| Rotational Speed | 65% - 75% of critical speed | Creates cataracting motion for maximum impact |

| Grinding Media Charge | 30% - 45% of mill volume | Balances grinding contacts and ball movement |

| Material Charge | Fills void space between balls | Prevents energy-wasting ball-on-ball contact |

| Media Size | Graduated mix based on feed size | Matches impact energy to particle size for effective breakdown |

Ready to transform your ball mill into a precise and efficient processing unit? The experts at KINTEK are here to help. We specialize in lab equipment and consumables, providing tailored solutions for your laboratory's grinding and milling needs. Whether you're focused on maximizing throughput, achieving a finer grind, or minimizing operational costs, our team can help you select the right equipment and optimize your process for peak performance. Contact KINTEL today to discuss how we can enhance your lab's efficiency and productivity!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?