Properly maintaining a sieve shaker is a critical process focused on two key areas: preserving the integrity of the test sieves and ensuring the consistency of the mechanical shaking action. This involves a routine of inspection, cleaning, and performance verification to guarantee that your particle size analysis remains accurate, repeatable, and reliable over the long term.

Your sieve shaker is an instrument of precision. Its maintenance is not just about preventing breakdowns; it is the fundamental practice that safeguards the validity of your analytical results. Consistent maintenance directly translates to consistent data.

Why Maintenance is Critical for Accurate Analysis

A sieve shaker's entire purpose is to apply consistent mechanical energy to a stack of sieves to achieve predictable particle separation. Any deviation in this system compromises the results.

Preserving Sieve Integrity

The test sieve itself is the most critical and fragile component. Its woven wire mesh, with precisely calibrated openings, is what performs the actual separation.

Damage to the mesh, such as stretching, tearing, or clogging (blinding), directly alters the effective opening size. This invalidates any analysis performed with that sieve.

Proper maintenance ensures each sieve in your stack conforms to its stated specification, preventing inaccurate particle size distribution data.

Ensuring Consistent Vibration

The shaker's drive mechanism, typically a vibration motor, is designed to produce a specific motion—often a combination of circular and vertical forces.

If the motor's performance degrades or the unit is not perfectly level and secure, the energy transmitted to the sieve stack becomes inconsistent. This leads to poor separation efficiency and results that cannot be reliably reproduced.

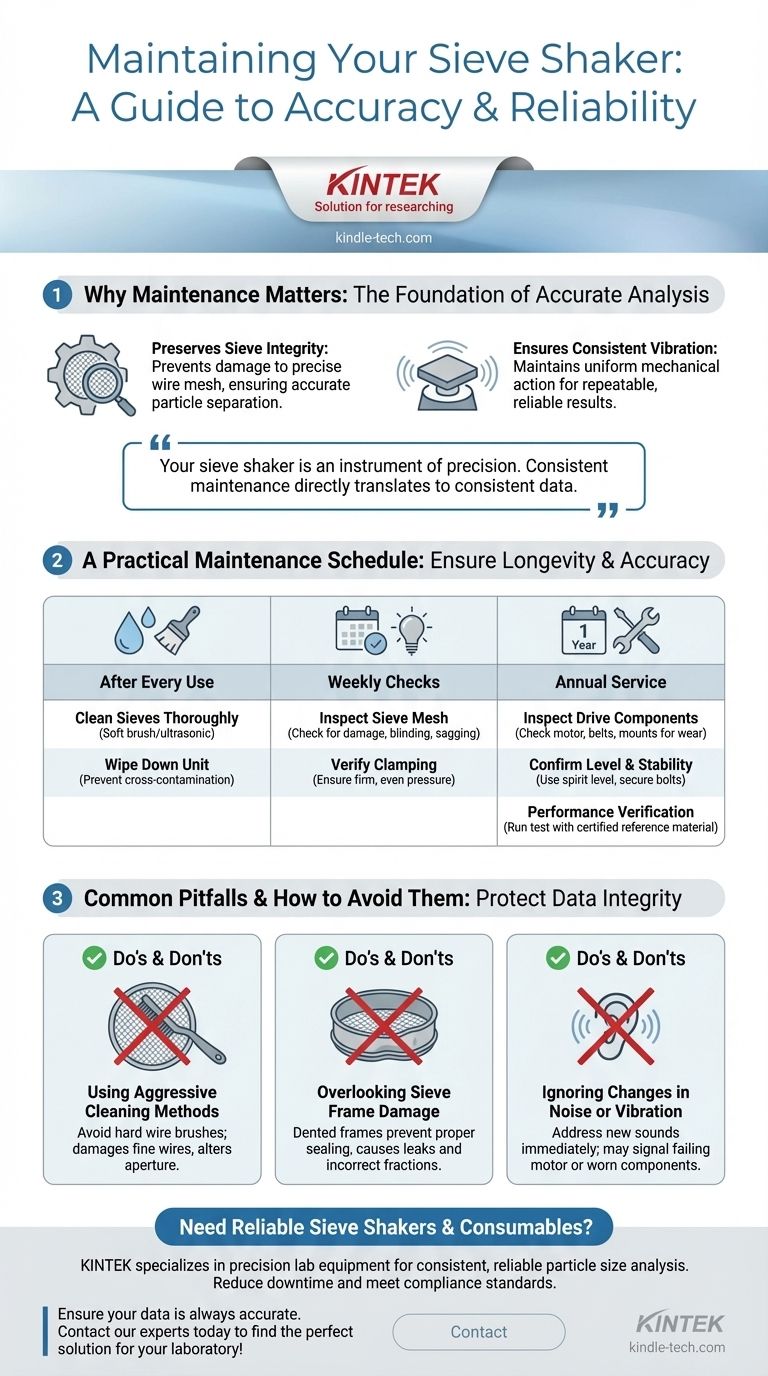

A Practical Maintenance Schedule

A structured maintenance routine is the most effective way to ensure longevity and accuracy. This can be broken down into tasks based on frequency.

After Every Use

- Clean the Sieves: Thoroughly clean each sieve used. Tap the frame to dislodge most particles, then use a soft, appropriate sieve cleaning brush. For fine powders, ultrasonic cleaners are highly effective.

- Wipe Down the Unit: Clean the shaker base and any surfaces where sample material may have spilled. This prevents cross-contamination between tests.

Weekly Checks

- Inspect Sieve Mesh: Hold each sieve up to a light source. Look for any signs of damage, such as torn wires, stretched areas (sagging), or dents.

- Check for Blinding: Inspect the mesh for clogged openings that could not be removed by standard cleaning. If a significant number of openings are blocked, the sieve's performance is compromised.

- Verify Clamping Mechanism: Ensure the mechanism that holds the sieve stack in place is functioning correctly and can apply firm, even pressure.

Annual Service

- Inspect Drive Components: Visually inspect the motor and any belts or mounts for signs of wear, cracking, or fatigue.

- Confirm Level and Stability: Use a spirit level to confirm the shaker is perfectly level on its bench. Check that all mounting bolts are secure.

- Performance Verification: Run a test using a certified reference material with a known particle size distribution. Compare your results to the certificate to verify the entire system (shaker and sieves) is performing correctly.

Common Pitfalls and How to Avoid Them

Even with a schedule, certain mistakes can undermine your efforts. Being aware of these common pitfalls is essential for maintaining data integrity.

Using Aggressive Cleaning Methods

Never use hard wire brushes or sharp tools to dislodge particles from a sieve mesh. This will inevitably damage the fine wires, altering the aperture size and rendering the sieve useless for accurate analysis.

Overlooking Sieve Frame Damage

A dented or warped sieve frame is a serious issue. A damaged frame prevents a proper seal within the sieve stack, allowing particles to leak between sieves and leading to incorrect fraction sizes. It also prevents the sieve from sitting flat, which can affect vibration transfer.

Ignoring Changes in Noise or Vibration

If the shaker begins to sound different or vibrate more erratically, do not ignore it. This is often the first sign of a failing motor, worn-out mount, or an unbalanced internal component. Address it immediately to prevent catastrophic failure or a gradual, unnoticed decline in performance.

Applying This to Your Lab's Goal

Your specific maintenance intensity should match the demands of your work.

- If your primary focus is high-stakes R&D or pharmaceutical compliance: Your protocol must include daily sieve inspections and frequent (quarterly or semi-annual) performance verification with reference materials.

- If your primary focus is routine industrial quality control: Emphasize robust daily cleaning and weekly inspections for wear and tear, especially on sieves used for abrasive materials.

- If your primary focus is occasional academic or exploratory testing: The most critical step is thorough cleaning and proper storage after every use to prevent corrosion or accidental damage during downtime.

Ultimately, disciplined maintenance is the foundation that ensures your sieve shaker remains a reliable tool for generating accurate data.

Summary Table:

| Maintenance Task | Frequency | Key Action |

|---|---|---|

| Clean Sieves & Unit | After Every Use | Remove particles, prevent contamination |

| Inspect Sieve Mesh & Clamping | Weekly | Check for damage, blinding, and secure fit |

| Performance Verification & Drive Inspection | Annually | Test with reference material, inspect motor |

Need Reliable Sieve Shakers or Consumables for Your Lab?

Proper maintenance is key, but it starts with quality equipment. KINTEK specializes in precision lab equipment and consumables, including durable sieve shakers and certified test sieves designed for long-term accuracy and ease of maintenance.

We help you:

- Achieve consistent, reliable particle size analysis.

- Reduce downtime with robust, easy-to-maintain equipment.

- Meet strict compliance standards for pharmaceuticals, R&D, and quality control.

Ensure your data is always accurate. Contact our experts today to find the perfect sieve shaker solution for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What are the precautions of sieve shaker? Ensure Accurate Particle Analysis & Protect Your Equipment

- What is the use of vibrating sieve machine? Achieve Precise Particle Size Analysis for Your Lab

- What role does a laboratory vibrating sieve shaker play in the LiFePO4 powder processing workflow? Ensure Batch Quality

- What are the applications of sieving machine? From Mining to Pharmaceuticals