Properly storing biomass pellets is fundamentally about protecting them from moisture and ensuring adequate ventilation. This means keeping them in a dry, covered location, raised off the ground, and away from any source of water. For sealed bags, this is straightforward, but for bulk storage, specific container designs and safety protocols are critical to prevent fuel degradation and mitigate serious safety hazards.

Storing pellets isn't just about keeping them dry to preserve their energy value. The core challenge is balancing moisture protection with the need for ventilation to prevent the dangerous buildup of carbon monoxide (CO) gas, a natural byproduct of wood decomposition.

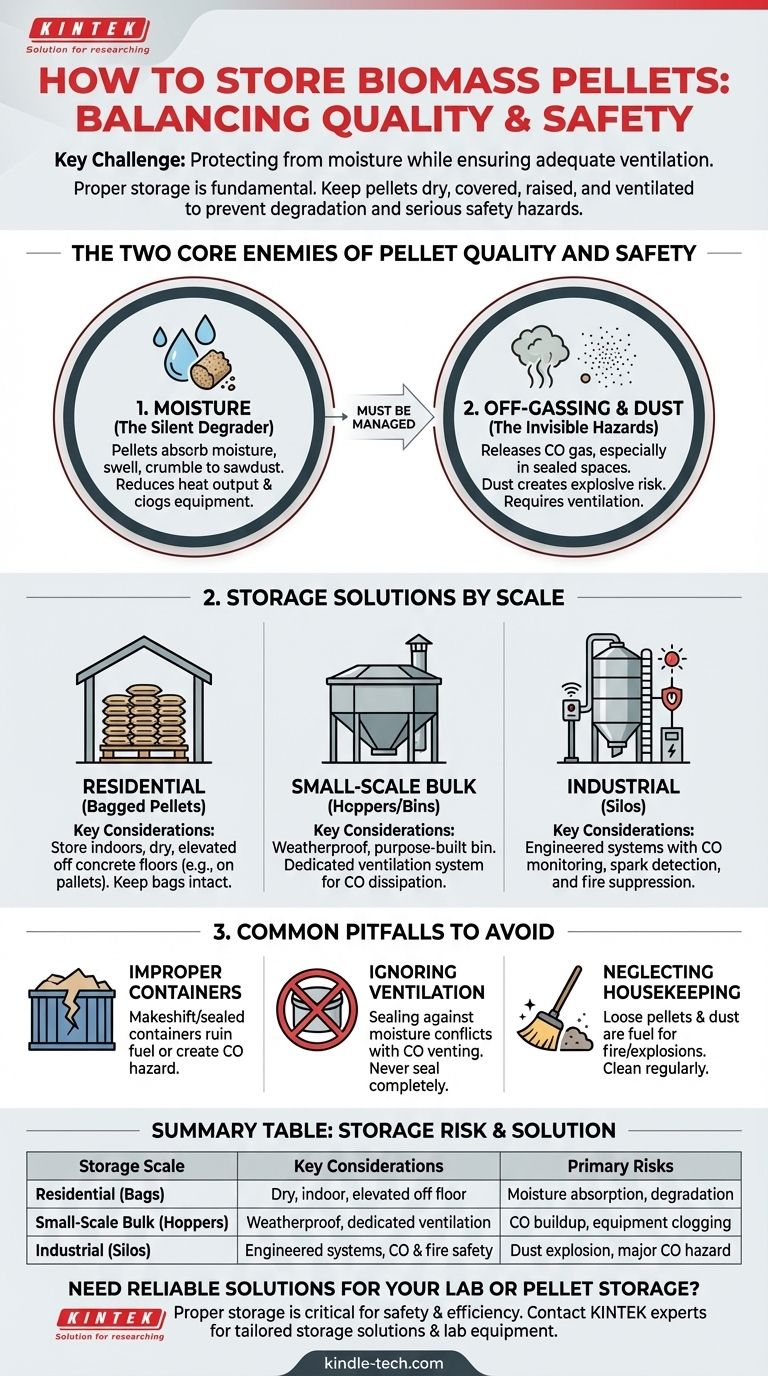

The Two Core Enemies of Pellet Quality and Safety

To store pellets effectively, you must manage two primary threats: moisture, which ruins the fuel, and the invisible gases and dust created by the pellets themselves, which pose significant safety risks.

Moisture: The Silent Degrader

Biomass pellets are hygroscopic, meaning they readily absorb moisture from the air, much like a sponge.

When pellets get wet, they swell and crumble back into sawdust. This process, known as degradation, destroys their density and drastically reduces their heat output or energy value.

Furthermore, degraded pellets can clog the auger and feed systems of automated stoves and boilers, leading to equipment failure.

Off-Gassing: The Invisible Hazard

As a natural wood product, pellets slowly decompose over time. This process releases several gases, most dangerously carbon monoxide (CO).

In a poorly ventilated or sealed space, this colorless and odorless gas can accumulate to lethal concentrations. This is the single most critical safety concern for any bulk pellet storage system.

Combustible Dust: The Explosive Risk

The friction of pellets rubbing against each other creates fine wood dust. When this dust is suspended in the air within an enclosed space, it can become highly combustible.

A simple spark from static electricity or a piece of equipment can be enough to trigger a dust explosion. This risk is most acute in large-scale commercial or industrial facilities.

Storage Solutions by Scale

The right storage method depends entirely on the quantity of pellets you are handling, from a few bags for a home stove to a silo for an industrial plant.

Residential Storage (Bagged Pellets)

For homeowners using bagged pellets, the goal is simple: keep the bags dry and intact.

Store bags indoors in a dry basement, garage, or shed. Crucially, place them on a pallet or shelving to keep them off a concrete floor, which can "sweat" and transmit moisture.

Stack bags carefully to avoid tearing the plastic, and keep the area clean of any loose pellets or dust.

Small-Scale Bulk Storage (Hoppers and Bins)

For homes or small businesses with automated boilers, purpose-built bulk hoppers are common.

These bins must be completely weatherproof to protect from rain and snow. They must also be equipped with a dedicated ventilation system to safely dissipate the CO produced by off-gassing.

Never use a simple, completely sealed container, as it creates a high risk of CO buildup.

Large-Scale and Industrial Storage (Silos)

For commercial and industrial use, professionally engineered silos are the standard.

These systems are designed with integrated safety features as a top priority. This includes active ventilation, gas monitoring systems to detect CO, spark detection, and fire suppression systems to manage the risk of dust explosion.

Common Pitfalls to Avoid

Mistakes in pellet storage often stem from underestimating the risks involved. A few common errors can lead to wasted fuel or dangerous situations.

The Cost of Improper Containers

Using a makeshift, non-ventilated container or simply leaving a bulk pile under a tarp is a significant mistake. A leaky cover will ruin the fuel, while a perfectly sealed container can become a CO hazard.

The upfront investment in a purpose-built storage solution prevents the far greater costs of wasted fuel, equipment damage, or a safety incident.

Ignoring Ventilation

This is the most dangerous pitfall. The natural instinct to seal a container tightly against moisture directly conflicts with the need to vent CO.

Any bulk storage system, regardless of size, must have a clear path for air exchange that does not allow water to enter. Professional systems have engineered vents designed for this purpose.

Neglecting Housekeeping

Allowing loose pellets and fine dust to accumulate in and around the storage area is a critical error. This debris is not just messy; it is a primary fuel source for a potential fire or dust explosion.

Regularly cleaning the storage unit, transfer systems, and surrounding areas is an essential safety procedure, not just optional maintenance.

Making the Right Choice for Your Goal

Your storage strategy should directly align with the scale of your operation and your tolerance for risk.

- If your primary focus is home heating with bagged pellets: Prioritize a dry, indoor space and elevate bags off concrete floors to prevent moisture wicking.

- If your primary focus is automated heating with a bulk bin: Invest in a purpose-built, weatherproof hopper that includes a dedicated ventilation system to safely manage off-gassing.

- If your primary focus is commercial or industrial operation: Mandate professionally engineered silos with integrated CO monitoring, dust management, and fire suppression systems.

Treating pellet storage as an active safety system, not just passive warehousing, is the key to preserving fuel quality and ensuring a safe environment.

Summary Table:

| Storage Scale | Key Considerations | Primary Risks |

|---|---|---|

| Residential (Bags) | Dry, indoor location; elevated off concrete floor | Moisture absorption, degradation |

| Small-Scale Bulk (Hoppers) | Weatherproof container; dedicated ventilation system | CO buildup, equipment clogging |

| Industrial (Silos) | Engineered systems with CO monitoring & fire suppression | Dust explosion, major CO hazard |

Need a reliable solution for your biomass pellet storage or lab equipment needs?

Proper storage is critical for safety and efficiency, whether you're handling fuel pellets or sensitive laboratory materials. At KINTEK, we specialize in providing durable, safe, and efficient lab equipment and consumables tailored to your specific requirements. Our expertise ensures your materials—from biomass fuels to lab samples—are stored under optimal conditions to maintain integrity and safety.

Contact our experts today to discuss how KINTEK can support your laboratory or processing facility with tailored storage solutions and high-quality equipment.

Visual Guide

Related Products

- Button Battery Storage Box for Battery Lab

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

People Also Ask

- Why is an argon glove box required for LTPO battery assembly? Ensure High-Purity Inert Environments for Li-Ion Research

- What is the importance of using an inert atmosphere glove box for all-solid-state lithium batteries? Secure Cell Safety

- What function do PTFE baskets serve in underground hydrogen storage? Ensure Chemical Purity in Geochemical Experiments

- What are the advantages of using high-grade stainless steel for experimental Zinc-Air battery cells? Ensure Precision.

- How is plastic waste different from other types of waste? The Hidden Threat of Microplastics