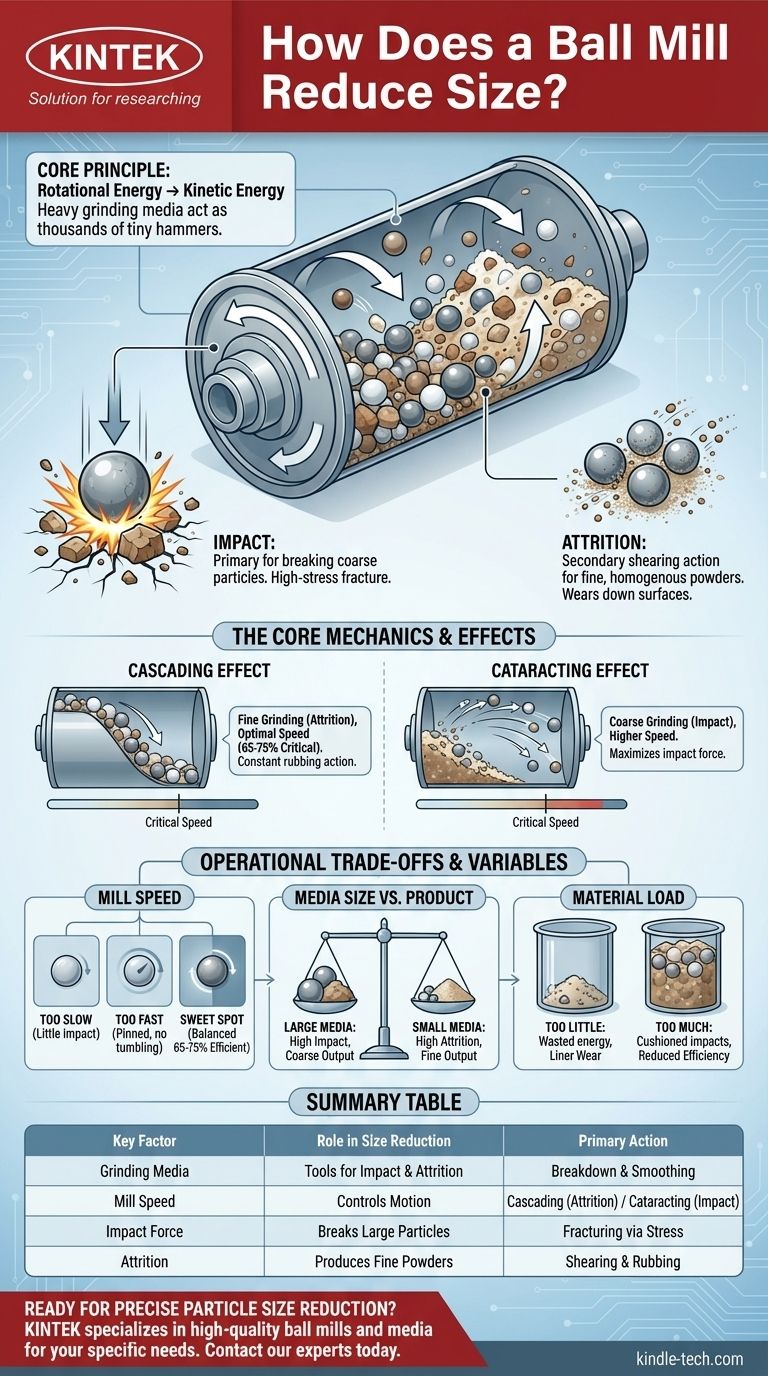

In essence, a ball mill reduces material size through a combination of impact and abrasion. Inside a rotating cylinder, heavy grinding media—typically steel or ceramic balls—are lifted and then fall onto the material, fracturing it. As the contents tumble, a secondary grinding action occurs as particles are rubbed between the moving balls.

The core principle is the conversion of rotational energy into kinetic energy. The mill uses the force of gravity to turn the tumbling balls into thousands of tiny hammers, creating high-stress impact and shear forces that systematically break down coarse materials into a fine powder.

The Core Mechanics of Size Reduction

To truly understand the process, we must look at the specific forces at play inside the mill's rotating drum. The final particle size is not a result of chance but of controlled mechanical actions.

The Role of Grinding Media

The "balls" inside the mill are the tools that perform the work. This grinding media can be made of various materials, such as high-carbon steel, stainless steel, or ceramics, chosen based on the material being processed.

The size of the media is critical. Larger, heavier balls are used to create powerful impact forces needed to fracture large, coarse feed particles. Smaller balls have more surface area and are used to grind particles into a much finer powder through attrition.

The Cascading and Cataracting Effect

As the mill cylinder rotates, it carries the grinding media and the material upward. The speed of this rotation is crucial.

At a specific "critical speed," the media is lifted high along the cylinder wall and then tumbles back down in a cascading motion. This creates a constant grinding and shearing action, ideal for fine grinding.

If the speed is increased further, the media is thrown across the drum in a projectile motion, known as cataracting. This maximizes the impact force and is highly effective for breaking down coarse materials quickly.

Size Reduction by Impact

The primary mechanism for breaking large particles is impact. As the heavy balls are lifted and then fall, they strike the material with significant force.

This impact creates stress that exceeds the material's strength, causing it to fracture. This is the dominant action at the beginning of the milling process when dealing with larger feed sizes.

Size Reduction by Attrition

The secondary, and equally important, mechanism is attrition. This is a shearing and rubbing action that occurs as the balls and material particles tumble over and against each other.

This action wears down the surfaces of the particles, making them smaller and smoother. Attrition is the key to producing very fine, homogenous powders and is maximized by using smaller grinding media to increase the number of contact points.

Understanding the Operational Trade-offs

The efficiency and outcome of a ball milling process are not automatic. They depend on a careful balance of several key variables, and a misunderstanding of these can lead to poor results or wasted energy.

The Critical Factor of Mill Speed

The speed of rotation is arguably the most important parameter.

- Too slow: The media will simply roll or slide down the cylinder wall, resulting in very little impact or effective grinding.

- Too fast: Centrifugal force will pin the media and material against the cylinder wall, preventing any tumbling or impact from occurring.

- The "sweet spot": Optimal speed is typically between 65-75% of the critical speed, balancing impact and attrition for efficient grinding.

Media Size vs. Final Product

There is a direct trade-off between the size of the grinding media and the fineness of the final product.

Using large balls provides the high-impact energy needed to break down coarse feed but is inefficient at producing ultra-fine particles. Conversely, small balls excel at fine grinding through attrition but lack the impact force to break down large particles effectively.

The Importance of Material Load

The amount of material inside the mill, known as the charge, affects efficiency.

Too little material leads to wasted energy, as the balls primarily impact each other and the mill liner, causing excessive wear. Too much material can cushion the impacts of the grinding media, dramatically reducing the effectiveness of size reduction.

Making the Right Choice for Your Goal

Controlling the milling process allows you to precisely engineer the characteristics of your final product. The key is to align the operational parameters with your desired outcome.

- If your primary focus is coarse grinding or initial breakdown: You must maximize impact forces by using larger, denser grinding media and operating at a speed that promotes a cataracting motion.

- If your primary focus is creating an ultra-fine, homogenous powder: You must maximize attrition by using a larger quantity of smaller media to increase surface area and grinding contact points, operating at a cascading speed.

By understanding these core principles, you can transform the ball mill from a simple container into a precise tool for material processing.

Summary Table:

| Key Factor | Role in Size Reduction |

|---|---|

| Grinding Media | Heavy balls (steel/ceramic) act as tools for impact and attrition. |

| Mill Speed | Controls the media's motion (cascading vs. cataracting) for different grinding actions. |

| Impact Force | Primary mechanism for breaking large, coarse particles. |

| Attrition | Secondary shearing action for producing fine, homogenous powders. |

Ready to achieve precise particle size reduction in your lab?

KINTEK specializes in high-quality ball mills and grinding media tailored to your specific material processing needs. Whether you require coarse grinding or ultra-fine powders, our expertise ensures you get the right equipment for maximum efficiency and consistent results.

Contact our experts today to discuss your application and find the perfect grinding solution for your laboratory.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Powerful Plastic Crusher Machine

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

People Also Ask

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability