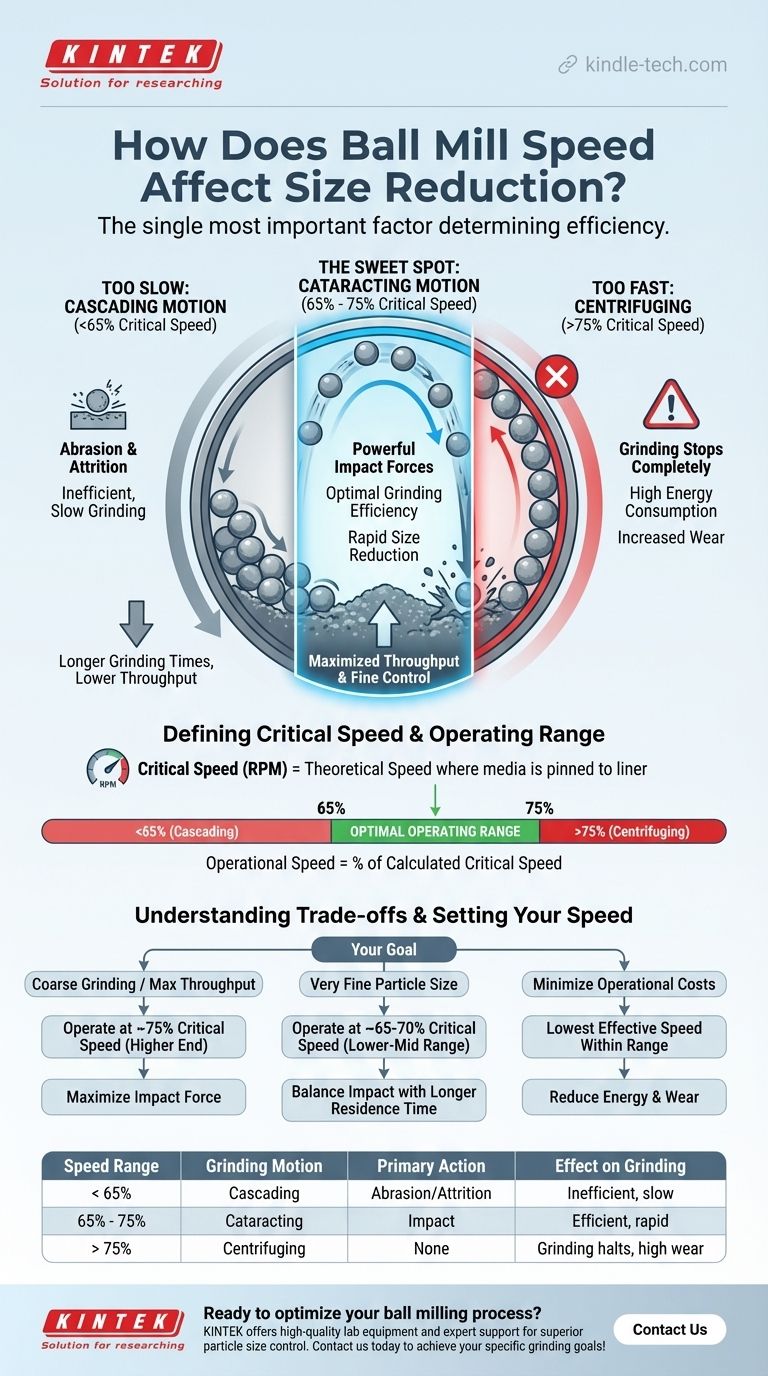

The speed of a ball mill directly dictates the type and intensity of the grinding action, which is the single most important factor in determining the efficiency of particle size reduction. There is a precise operational window; operating too slowly results in inefficient grinding, while operating too fast is counterproductive and can halt the size reduction process entirely.

The core principle is that optimal grinding occurs when the mill's rotational speed creates a "cataracting" motion, where the grinding media is lifted high up the mill wall and then tumbles down onto the material. This motion provides the impact energy necessary for effective and efficient size reduction.

The Physics of Ball Mill Grinding

To control the outcome of your milling process, you must first understand the three distinct modes of motion that occur inside the mill, each determined by its rotational speed.

Cascading Motion (Too Slow)

At low speeds, the grinding media (the balls) simply tumbles over itself, sliding down the face of the mass of material.

This motion, known as cascading, results in size reduction primarily through abrasion or attrition. It's a rubbing and wearing action that is not effective for breaking down larger, harder particles.

Cataracting Motion (The Sweet Spot)

As speed increases, the media is carried further up the wall of the rotating mill. It reaches a point where it breaks free from the wall and is thrown across the mill's diameter.

This is cataracting. The media crashes down onto the material below, creating the powerful impact forces that are essential for rapid and efficient breakage of particles. This is the ideal state for most grinding operations.

Centrifuging (Too Fast)

If the mill rotates too quickly, centrifugal force overcomes gravity. The grinding media becomes pinned against the inner wall of the mill.

In this state, there is no tumbling, no impact, and very little relative motion. Grinding stops almost completely, while energy consumption and wear on the mill liner dramatically increase.

Defining the "Critical Speed"

The concept of "critical speed" is the theoretical and practical foundation for setting your mill's operational parameters.

What is Critical Speed?

Critical speed is the theoretical rotational speed (in RPM) at which the outermost layer of grinding media would be held against the mill liner by centrifugal force.

It is a calculated value based on the mill's internal diameter and is used as a benchmark, not an actual operating speed.

The Operating Speed Formula

In practice, the operational speed of a ball mill is always expressed as a percentage of its calculated critical speed.

This allows for a standardized way to discuss and compare mill operations, regardless of their physical size.

The Optimal Operating Range

For the vast majority of applications, the most efficient grinding occurs when the mill is operated between 65% and 75% of its critical speed.

This range ensures a strong cataracting motion, maximizing impact energy while preventing the media from centrifuging.

Understanding the Trade-offs

Choosing a speed, even within the optimal range, involves balancing competing priorities like throughput, final particle size, and operational cost.

The Cost of Running Too Slow

Operating below the optimal range (<65% of critical speed) results in a predominantly cascading motion. This leads to longer grinding times, lower throughput, and inefficiency, especially for coarser feed materials.

The Danger of Running Too Fast

Operating above the optimal range (>75% of critical speed) pushes the media closer to the mill liner. This increases wear on both the media and the liners, consumes more power, and raises the risk of centrifuging, which would halt production.

Speed Isn't Everything: Other Key Variables

While speed is paramount, it works in concert with other factors that influence the final product.

The Role of Grinding Media

The size of your grinding media is also critical. To be effective, the media must be substantially larger than the largest pieces of material you intend to grind.

Furthermore, the smaller the grinding media particles, the smaller the final particle size of the product will be, as you increase the number of impact points and promote finer attrition.

Mill Filling (Load Volume)

The volume of the mill occupied by the grinding media (typically 30-45%) also affects performance. Too little media reduces the number of impacts, while too much can dampen the cataracting motion and hinder efficiency.

How to Set the Right Speed for Your Goal

Use the principles of critical speed to align the mill's operation with your specific production objective.

- If your primary focus is coarse grinding or maximizing throughput: Operate toward the higher end of the optimal range (~75% of critical speed) to generate maximum impact force.

- If your primary focus is achieving a very fine particle size: Operate in the lower-to-mid optimal range (~65-70% of critical speed) to balance impact with longer residence time, which promotes finer grinding.

- If your primary focus is minimizing operational costs: Find the lowest speed within the optimal range that meets your production targets to reduce energy consumption and wear on liners and media.

Ultimately, controlling ball mill speed is about precisely controlling the physics of impact to achieve your desired particle size with maximum efficiency.

Summary Table:

| Speed Range (% of Critical Speed) | Grinding Motion | Primary Action | Effect on Grinding |

|---|---|---|---|

| < 65% | Cascading | Abrasion/Attrition | Inefficient, slow, poor for coarse particles |

| 65% - 75% (Optimal) | Cataracting | Impact | Efficient, rapid size reduction |

| > 75% | Centrifuging | None | Grinding halts, high wear & energy use |

Ready to optimize your ball milling process for superior particle size control and efficiency? KINTEK specializes in high-quality lab equipment and consumables, providing the precise tools and expert support your laboratory needs. Whether you're scaling up or refining your grinding parameters, our solutions are designed to enhance your results. Contact us today to discuss how we can help you achieve your specific grinding goals!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the primary purpose of using WC milling jars and balls? Achieve Ultra-Pure W-TiC Composite Alloying

- How does a dry impact-blending device compare to a planetary ball mill? Optimize Your Solid-State Battery Composites

- What is the specific role of a planetary ball mill in the preparation of Ag-SnO2-Y2O3 composite powders?

- What is the role of a ball mill and corundum grinding balls in boron carbide ceramic preparation? Ensure High Purity

- What is the function of a planetary ball milling system? Prepare CrFeAlTi Composite Powders for Ceramic Coatings

- What is the function of a planetary ball mill in mechanochemical synthesis? Enhance Your Ceramic Material Preparation

- What are the different size of balls in ball mill? Optimize Your Grinding Efficiency

- How does particle size affect ball milling? Master the Science for Efficient Size Reduction