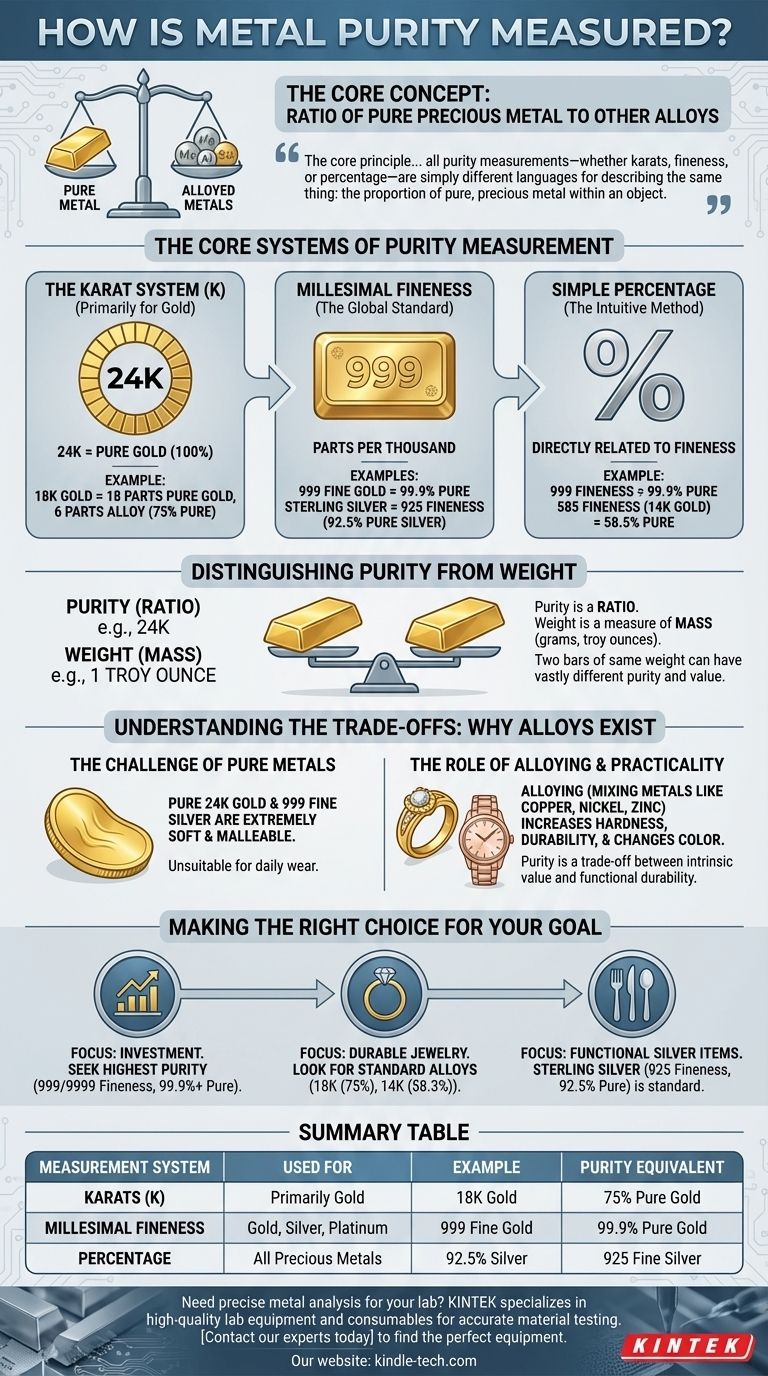

The purity of precious metals is most often measured using the karat system for gold, or by millesimal fineness and simple percentage for gold, silver, and platinum. These systems are different ways of expressing the ratio of pure precious metal to other alloyed metals in the final product.

The core principle to understand is that all purity measurements—whether karats, fineness, or percentage—are simply different languages for describing the same thing: the proportion of pure, precious metal within an object.

The Core Systems of Purity Measurement

To accurately assess the value and properties of a metal item, you must first understand the system being used to describe its composition. While they seem different, they are all measuring the same fundamental quality.

The Karat System (Primarily for Gold)

The karat (K) system is a traditional unit that measures the purity of gold in 24 parts.

Pure gold is 24 karats (24K), meaning all 24 out of 24 parts are gold.

An 18K gold item contains 18 parts pure gold and 6 parts other metals (alloys), making it 75% pure gold.

Millesimal Fineness (The Global Standard)

Millesimal fineness is a more precise and universal system that denotes the purity in parts per thousand.

This system is the standard for investment-grade bullion and is stamped on most gold, silver, and platinum bars. For example, a gold bar stamped "999" is 999 parts pure gold per 1,000 parts, or 99.9% pure.

Sterling silver has a fineness of 925, meaning it is 92.5% pure silver and 7.5% other metals, typically copper.

Simple Percentage (The Intuitive Method)

This is the most straightforward way to think about purity and is directly related to millesimal fineness.

A fineness of 999 is simply 99.9% pure. A fineness of 585 (common in 14K gold) is 58.5% pure.

Distinguishing Purity from Weight

It is critical not to confuse purity with weight. Purity is a ratio, while weight is a measure of mass.

Weight is typically measured in grams or troy ounces (31.1 grams). Two gold bars can have the exact same weight, but if one is 24K (99.9% pure) and the other is 14K (58.3% pure), their value and composition are vastly different.

Understanding the Trade-offs: Why Alloys Exist

Lower purity levels are not necessarily a sign of low quality. They are often the result of an intentional engineering decision to improve the metal's practical characteristics.

The Challenge of Pure Metals

Pure 24K gold and 999 fine silver are extremely soft and malleable.

This softness makes them unsuitable for items that must withstand daily wear and tear, such as rings, coins in circulation, or silverware.

The Role of Alloying

To solve this, metallurgists mix pure precious metals with other metals, creating an alloy.

Common alloying metals like copper, nickel, zinc, and palladium are added to increase hardness, improve durability, and even change the color (e.g., copper creates "rose gold").

Purity vs. Practicality

The choice of purity is a direct trade-off between the intrinsic value of the pure metal and its functional durability for a specific purpose. High purity is ideal for investment bullion, while robust alloys are necessary for jewelry and functional objects.

Making the Right Choice for Your Goal

Understanding these systems allows you to select the right metal for your specific objective.

- If your primary focus is investment: Seek the highest purity possible, typically expressed as 999 or 9999 fineness (99.9% or 99.99% pure).

- If your primary focus is durable jewelry: Look for standard alloys like 18K (75%) or 14K (58.3%) gold, which balance value with strength.

- If your primary focus is functional silver items: Sterling silver (925 fineness or 92.5% pure) is the industry standard for combining beauty and practicality.

By learning to interpret these measurements, you can accurately assess the true quality and purpose of any precious metal item.

Summary Table:

| Measurement System | Used For | Example | Purity Equivalent |

|---|---|---|---|

| Karats (K) | Primarily Gold | 18K Gold | 75% Pure Gold |

| Millesimal Fineness | Gold, Silver, Platinum | 999 Fine Gold | 99.9% Pure Gold |

| Percentage | All Precious Metals | 92.5% Silver | 925 Fine Silver |

Need precise metal analysis for your lab? KINTEK specializes in high-quality lab equipment and consumables for accurate material testing. Whether you're analyzing precious metals or developing new alloys, our solutions ensure reliable results. Contact our experts today to find the perfect equipment for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is potassium bromide used as a reference compound in IR spectroscopy? Unlock Clear, Interference-Free Sample Analysis

- Why is programmed temperature control critical for Ce-TiOx/npAu catalysts? Achieve Precision in Catalyst Activation

- Why is a continuous flow of high-purity nitrogen required during the catalytic pyrolysis of plastics? Maximize Fuel Yield

- Is biomass cheaper than other energy sources? Unpacking the True Cost of Biomass Energy

- When was sputtering invented? From 1852 Discovery to 1920 Industrial Breakthrough

- What are the defects in the heat treatment process? Prevent Cracking, Warping, and Soft Spots

- What are the uses of pyrolysis bio-oil? A Guide to Fuel, Chemical, and Power Applications

- How long does pyrolysis take? From Seconds to Days for Bio-Oil or Biochar