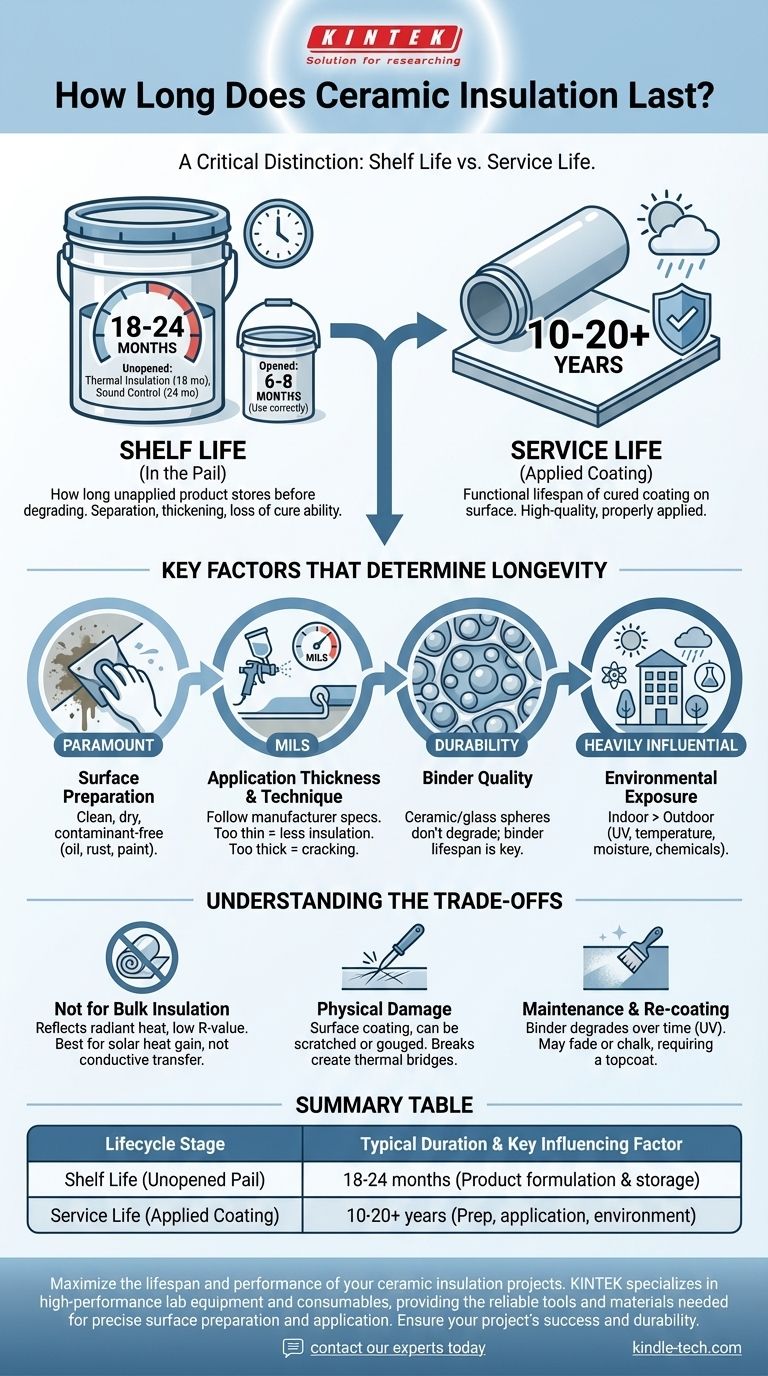

To be clear, there are two answers to this question: the shelf life of the liquid product in its container and the service life of the coating once it has been properly applied. An unopened pail of liquid ceramic insulation typically has a shelf life of 18 to 24 months, while a properly applied coating can last 10 to 20 years or more, similar to a high-quality industrial paint.

The most critical factor to understand is that the product's short shelf life in the can has no bearing on its long-term durability once applied. The key to a long service life is not the expiration date on the pail, but the quality of the surface preparation and application.

Shelf Life vs. Service Life: A Critical Distinction

Many users confuse the expiration date of the liquid product with the functional lifespan of the cured coating. These are two completely separate metrics that measure different things.

Understanding Shelf Life (The Product in the Pail)

Shelf life refers to how long the unapplied product can be stored before it begins to degrade. The components can separate, thicken, or lose their ability to cure correctly.

Based on typical manufacturer data, the shelf life is 18 months for thermal insulation products and 24 months for sound control variants. Once a container is opened, it should be used within 6 to 8 months if stored correctly.

Defining Service Life (The Applied Coating)

Service life is the true measure of longevity. It is the length of time the cured ceramic insulation coating will perform its function on a surface before needing maintenance or re-coating.

When applied correctly, a high-quality ceramic insulation coating can easily last 10 to 20 years. In many indoor or protected applications, its lifespan can match that of the substrate it's painted on.

Key Factors That Determine Longevity

The ultimate service life of a ceramic insulation coating is not guaranteed. It depends entirely on a few critical variables that are within the applicator's control.

Surface Preparation is Paramount

This is the single most important factor. An improperly prepared surface is the primary cause of premature coating failure. The substrate must be clean, dry, and free of any contaminants like oil, rust, or loose paint.

Application Thickness and Technique

The coating must be applied to the manufacturer's specified thickness (often measured in mils). Applying it too thin will reduce its insulating properties and durability. Applying it too thick can lead to improper curing and cracking.

The Quality of the Binder

Ceramic insulation is essentially a high-quality paint (typically acrylic or elastomeric) filled with microscopic ceramic or glass spheres. The ceramic spheres themselves do not degrade.

The lifespan of the coating is therefore determined by the durability of the binder that holds them together and adheres them to the surface.

Environmental Exposure

The working environment heavily influences service life. A coating on an indoor wall will last far longer than one on an exterior roof exposed to constant UV radiation, temperature cycles, moisture, and potential chemical contact.

Understanding the Trade-offs

While durable, ceramic insulation coatings have specific characteristics that define their use cases. Understanding their limitations is key to a successful project.

It Is Not a Replacement for Bulk Insulation

Ceramic coatings primarily work by reflecting radiant heat, not by stopping conductive heat transfer like fiberglass or foam. Their R-value is very low. They are best used to manage solar heat gain or to keep heat contained, not as a replacement for traditional insulation.

Susceptibility to Physical Damage

Because it is a surface coating, it can be scratched or gouged. Any physical damage that breaks the surface of the coating will create a thermal bridge, compromising its insulating performance in that specific area.

Maintenance and Re-coating

Over many years, the binder will eventually degrade from UV exposure, just like any paint. It may begin to look faded or "chalky." At this point, it may require a new topcoat to extend its life and refresh its appearance.

Making the Right Choice for Your Goal

To maximize the lifespan of your ceramic insulation, align your approach with your primary objective.

- If your primary focus is maximum longevity: Invest heavily in professional surface preparation and application, ensuring every step of the manufacturer's data sheet is followed precisely.

- If your primary focus is a DIY project: Pay close attention to the expiration date on the pail and only purchase what you can use within a few months to avoid product waste.

- If your primary focus is protecting assets in a harsh environment: Choose an industrial-grade product with a robust binder specifically designed for UV resistance and chemical exposure.

Ultimately, the lifespan of applied ceramic insulation is a direct result of the quality of the work.

Summary Table:

| Lifecycle Stage | Typical Duration | Key Influencing Factor |

|---|---|---|

| Shelf Life (Unopened Pail) | 18-24 months | Product formulation and storage conditions |

| Service Life (Applied Coating) | 10-20+ years | Surface preparation, application quality, and environmental exposure |

Maximize the lifespan and performance of your ceramic insulation projects. The longevity of your coating is a direct result of using the right materials and application techniques. KINTEK specializes in high-performance lab equipment and consumables, providing the reliable tools and materials needed for precise surface preparation and application. Ensure your project's success and durability—contact our experts today to discuss your specific laboratory or industrial coating needs.

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Custom CVD Diamond Coating for Lab Applications

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Can ceramic withstand high temperatures? Discover the Superior Materials for Extreme Heat

- What is the maximum temperature for ceramics? Find the Right Material for Your High-Temp Application

- What material is used for furnace insulation? Key Materials for Maximum Efficiency & Performance

- Why are platinum electrode wires wrapped in oxidized zirconia coils? Ensure Signal Integrity in High-Temp Systems

- What is ceramic insulation used for? Master High-Temperature Solutions for Industrial Efficiency