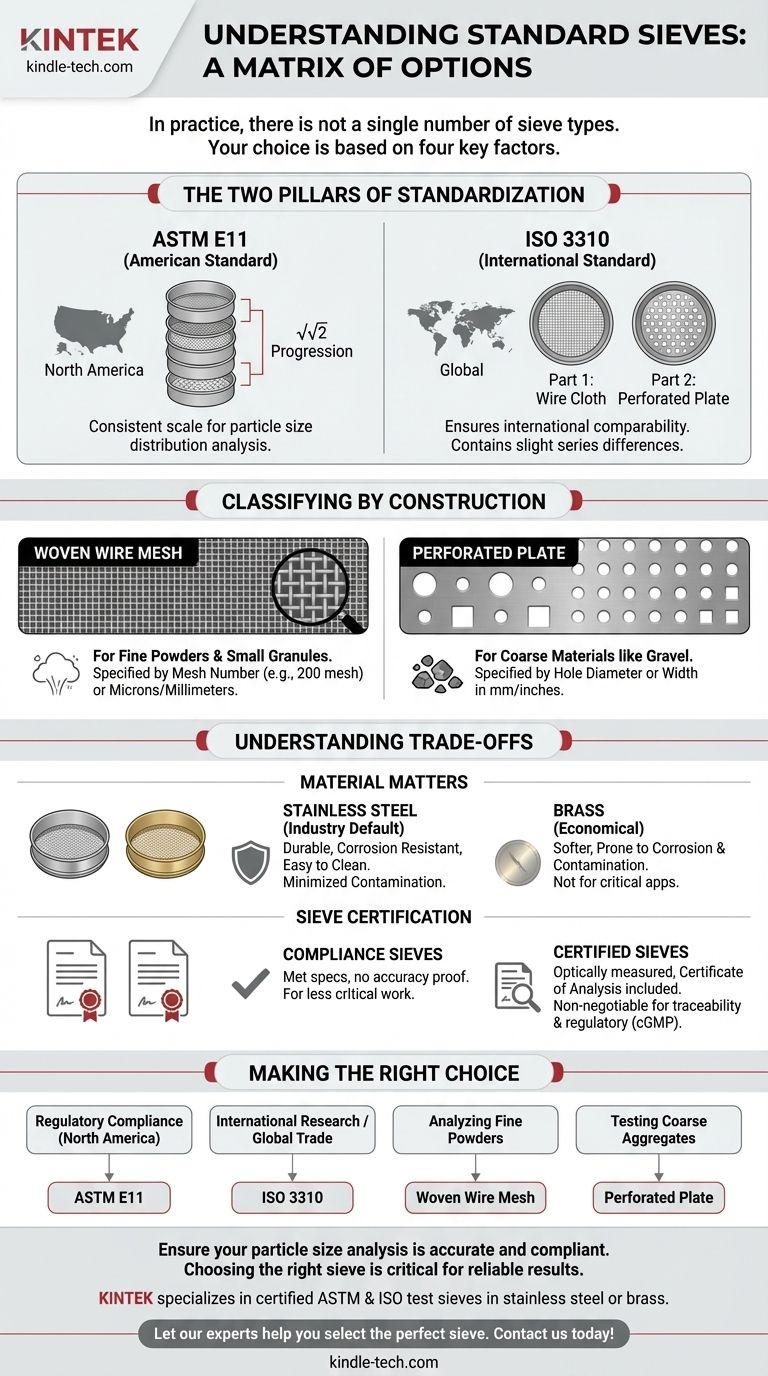

In practice, there is not a single number of standard sieve types, but rather two primary international standards that each define a comprehensive series of sieves: ASTM E11 and ISO 3310. The "type" of a sieve is determined by which standard it adheres to, its construction material, and its physical dimensions, creating a matrix of options rather than a simple count.

The most critical distinction is not how many types of sieves exist, but understanding that sieves are classified by two competing global standards—ASTM and ISO. Your choice between them is the first and most important decision, as it dictates the specific aperture sizes available for your particle analysis.

The Two Pillars of Sieve Standardization

The world of precision particle sizing is governed almost entirely by two sets of specifications. While they are very similar, they are not directly interchangeable, and knowing which one to use is essential for procedural consistency and regulatory compliance.

ASTM E11: The American Standard

The ASTM E11 specification is the predominant standard for test sieves in the United States and across North America. It defines a series of standard sieve opening sizes with a fixed progression based on the fourth root of two (√√2).

This mathematical progression ensures that each successive sieve in the main series has an opening that is approximately 1.189 times larger than the one before it. This creates a logical, consistent scale for particle size distribution analysis.

ISO 3310: The International Standard

The ISO 3310 standard is the globally recognized counterpart, used widely in Europe, Asia, and other regions. It is technically composed of two parts: ISO 3310-1 for metal wire cloth sieves and ISO 3310-2 for perforated metal plate sieves.

Like ASTM E11, the ISO standard specifies a series of preferred aperture sizes. While many ISO and ASTM sizes are very similar or identical (e.g., 1 mm), the overall series contains slight differences. Using an ISO-compliant set of sieves ensures your results are comparable to international labs and standards.

Beyond Standards: Classifying by Construction

Independent of the ASTM or ISO standard, sieves are fundamentally categorized by how their screening surface is made. This choice is dictated by the size of the particles you are measuring.

Woven Wire Mesh Sieves

These are the most common type of test sieves, used for analyzing materials ranging from fine powders up to small granules. The mesh is created by weaving individual metal wires together to form precise, square openings.

Woven wire sieves are specified by their mesh number (an ASTM term) or nominal aperture size in millimeters or microns. A higher mesh number indicates more wires per inch and therefore a smaller opening.

Perforated Plate Sieves

For separating larger, coarser materials like gravel, aggregates, or large agricultural products, woven wire is not practical. Instead, perforated plate sieves are used.

These consist of a solid sheet of metal (usually steel) with precisely sized holes punched into it. The openings can be either round or square and are specified by their diameter or width in millimeters or inches.

Understanding the Trade-offs

Selecting the right sieve involves more than just picking a standard and opening size. Material and certification level have significant impacts on cost, longevity, and data validity.

Material Matters: Brass vs. Stainless Steel

Historically, sieves were made with brass frames and mesh. While more economical, brass is softer, prone to corrosion, and can introduce contamination, making it unsuitable for many food, pharmaceutical, and chemical applications.

Stainless steel is now the industry default for nearly all precision applications. It is far more durable, resists corrosion and abrasion, is easy to clean, and minimizes the risk of sample contamination, ensuring the integrity of your analysis.

Sieve Certification: A Critical Detail

A common point of confusion is the difference between sieve grades.

- Compliance Sieves are manufactured to meet the specifications of ASTM E11 or ISO 3310 but do not include formal documentation proving their accuracy.

- Certified Sieves (or Inspection/Calibration Sieves) have been optically measured and are sold with a certificate of analysis that documents the actual measured openings of the specific sieve.

For any work that requires traceability, quality control documentation, or adherence to a regulatory framework like cGMP, certified sieves are non-negotiable. Compliance sieves are suitable only for less critical applications where absolute precision is not the primary goal.

Making the Right Choice for Your Application

Your choice of sieve depends entirely on your specific analytical goal, industry, and geographic location.

- If your primary focus is regulatory compliance in North America: You must use sieves certified to the ASTM E11 standard.

- If your primary focus is international research or global trade: Aligning with the ISO 3310 standard ensures your results are comparable worldwide.

- If you are analyzing fine powders (e.g., pharmaceuticals, flour, cement): You will require a woven wire mesh sieve series.

- If you are testing coarse aggregates (e.g., gravel, ore, construction materials): You will need a set of perforated plate sieves.

Understanding these classification systems empowers you to select the precise tool required for accurate and repeatable particle size analysis.

Summary Table:

| Classification | Key Options | Primary Use |

|---|---|---|

| Standard | ASTM E11, ISO 3310 | Determines aperture sizes & regional compliance |

| Construction | Woven Wire Mesh, Perforated Plate | Fine powders vs. coarse aggregates |

| Material | Stainless Steel, Brass | Durability, contamination resistance, and cost |

| Certification | Compliance, Certified | Critical for traceability and regulatory requirements |

Ensure your particle size analysis is accurate and compliant. Choosing the right sieve is critical for reliable results. KINTEK specializes in high-quality lab equipment and consumables, offering a full range of certified ASTM and ISO test sieves in stainless steel or brass to meet your laboratory's specific needs.

Let our experts help you select the perfect sieve for your application.

Contact us today for a consultation and to request a quote!

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Graphite Vacuum Continuous Graphitization Furnace

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What is the principle of sieving machine? Achieve Accurate Particle Size Separation

- What does a vibrating sieve do? Automate Particle Size Analysis for Accurate Results

- What is powder sieving? A Guide to Accurate Particle Size Separation

- What are the applications of sieving machine? From Mining to Pharmaceuticals