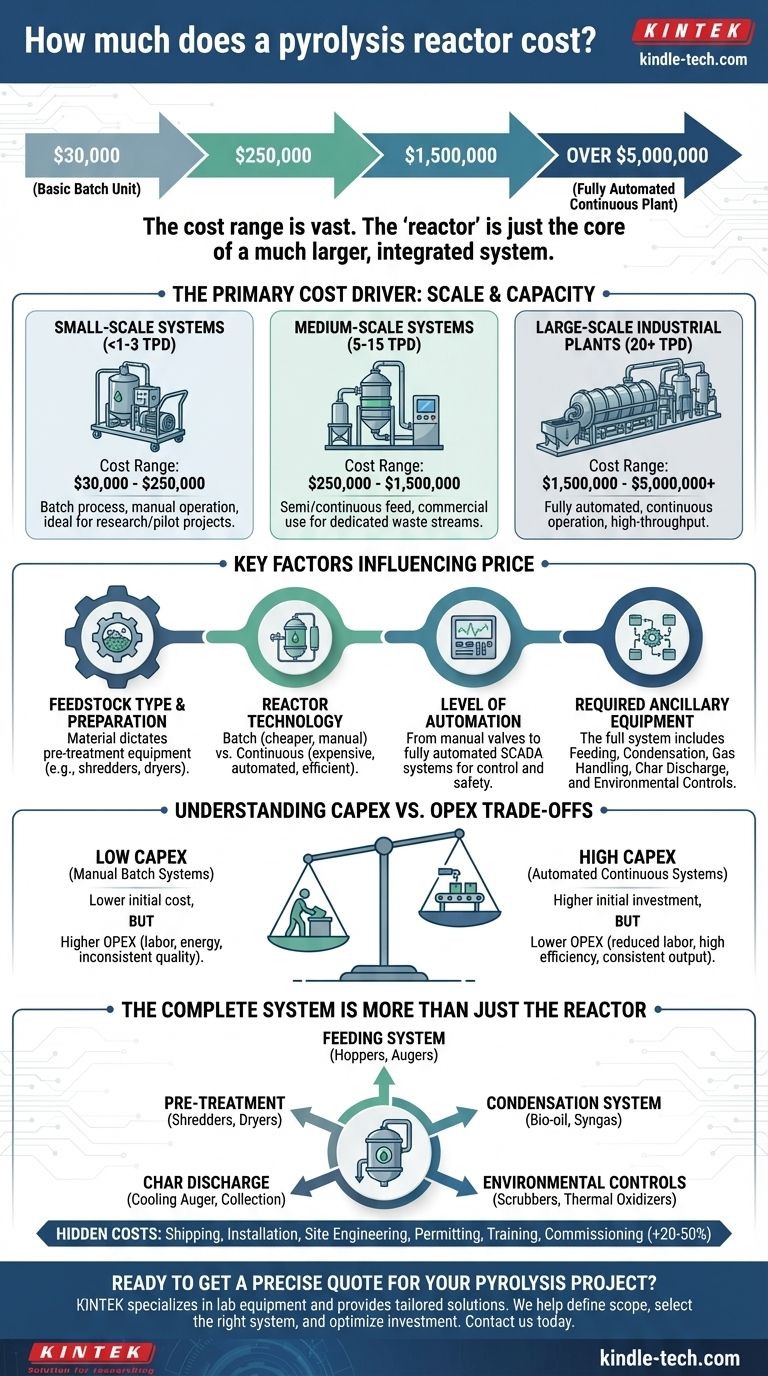

In short, a pyrolysis reactor can cost anywhere from $30,000 for a small, basic batch unit to well over $5,000,000 for a large-scale, fully automated continuous plant. This vast range exists because the "reactor" is just the core component of a much larger, integrated system. The final price is determined by its processing capacity, the type of material it handles, its level of automation, and the necessary ancillary equipment for pre-treatment and post-processing.

The most common mistake is budgeting only for the reactor. The true cost of a pyrolysis project includes the essential support systems—shredders, dryers, feeders, and post-processing equipment—which can often equal or exceed the cost of the reactor itself.

The Primary Cost Driver: Scale and Capacity

The single largest factor dictating the price of a pyrolysis system is its throughput, typically measured in tons per day (TPD) or kilograms per hour (kg/hr). Costs do not scale linearly; larger plants have a higher total cost but a lower cost per ton of capacity.

Small-Scale Systems (Under 1-3 TPD)

A small-scale system, often skid-mounted and using a batch process, generally ranges from $30,000 to $250,000. These are ideal for research, pilot projects, or very small, niche waste streams. Operation is typically manual, requiring labor to load feedstock and remove char after each cycle.

Medium-Scale Systems (5-15 TPD)

Medium-scale, commercial systems typically cost between $250,000 and $1,500,000. At this level, you begin to see semi-continuous or fully continuous-feed systems, which offer greater efficiency. These are suitable for smaller municipalities or businesses with a consistent, dedicated waste stream like tires or specific plastics.

Large-Scale Industrial Plants (20+ TPD)

Large industrial plants represent a significant capital investment, often starting at $1,500,000 and easily exceeding $5,000,000. These are fully automated, continuous-feed operations designed for high-throughput waste management or large-scale production of bio-oil, char, and syngas. The price is heavily influenced by the need for robust engineering, site preparation, and extensive pollution control systems.

Key Factors That Influence the Final Price

Beyond sheer size, several other technical and operational factors will dramatically impact your final quote.

Feedstock Type and Preparation

The material you plan to process dictates the required pre-treatment equipment. A system for clean, uniform wood chips is simpler and cheaper than one for mixed municipal plastic waste, which requires sorting, shredding, and washing. Factor in the cost of shredders, dryers, and feeding mechanisms, as these are rarely included in the base reactor price.

Reactor Technology (Batch vs. Continuous)

Batch reactors are the least expensive option. Feedstock is loaded, the unit is sealed and heated, and the products are removed at the end of the cycle. This results in higher labor costs and lower throughput.

Continuous reactors are more complex and expensive. They use augers or rotary kilns to constantly feed material in and discharge char, allowing for 24/7 operation. This higher upfront cost is offset by lower operational labor costs and much greater processing capacity.

Level of Automation

A basic system may have manual valves and simple temperature readouts. A fully automated plant uses a Supervisory Control and Data Acquisition (SCADA) system to monitor and control the entire process. This adds significant cost but increases safety, consistency, and efficiency while reducing the need for constant operator oversight.

Required Ancillary Equipment

A functional pyrolysis plant is more than just a furnace. You must budget for the complete system:

- Feeding System: Hoppers and augers to move feedstock into the reactor.

- Condensation System: Heat exchangers to cool the pyrolysis gas (syngas) and condense the liquid bio-oil.

- Gas Handling: Equipment to clean and either flare, store, or use the non-condensable syngas.

- Char Discharge: A cooling auger and collection system for the solid biochar.

- Environmental Controls: Scrubbers or thermal oxidizers to meet local air quality regulations.

Understanding the Trade-offs: CAPEX vs. OPEX

A critical mistake is focusing solely on the initial purchase price (Capital Expenditure or CAPEX) without considering the long-term running costs (Operational Expenditure or OPEX).

The Low CAPEX Trap

Cheaper, manual batch systems may seem attractive, but their operational costs can be very high. They require significant labor for loading and unloading, have lower energy efficiency, and produce inconsistent product quality. This path is suitable for research but rarely for a profitable commercial venture.

The High CAPEX Advantage

Expensive, fully automated continuous systems require a major upfront investment. However, their OPEX is substantially lower due to reduced labor needs, higher energy efficiency (often using their own syngas for fuel), and consistent, high-quality output. This is the standard model for serious commercial operations.

Hidden and Soft Costs

Remember to budget for costs beyond the equipment itself. These include shipping, installation, site engineering, permitting, operator training, and commissioning. These can easily add another 20-50% to the total project cost.

Making the Right Choice for Your Goal

To get a meaningful estimate, you must first define your objective.

- If your primary focus is research or academic proof-of-concept: A small-scale, skid-mounted batch reactor is your most cost-effective entry point.

- If your primary focus is processing a specific waste stream for a business (e.g., used tires): Plan for a medium-scale, continuous system and get detailed quotes that include all necessary pre- and post-processing equipment.

- If your primary focus is large-scale waste-to-energy or commodity production: Your project requires a comprehensive feasibility study and budgeting for a fully integrated, automated industrial plant with significant engineering and regulatory costs.

By clearly defining your goals and understanding all the components of a complete system, you can develop a realistic budget for a successful pyrolysis project.

Summary Table:

| System Scale | Typical Throughput | Estimated Cost Range | Key Characteristics |

|---|---|---|---|

| Small-Scale | < 1-3 TPD | $30,000 - $250,000 | Batch process, manual operation, ideal for research/pilot projects |

| Medium-Scale | 5-15 TPD | $250,000 - $1,500,000 | Semi/continuous feed, commercial use for dedicated waste streams |

| Large-Scale | 20+ TPD | $1,500,000 - $5,000,000+ | Fully automated, continuous operation, high-throughput industrial plants |

Ready to Get a Precise Quote for Your Pyrolysis Project?

Navigating the complex cost factors of pyrolysis systems—from reactor technology to full plant integration—requires expert guidance. KINTEK specializes in lab equipment and consumables, serving diverse laboratory needs with precision-engineered solutions.

We help you:

- Define your project scope—whether for research, waste processing, or large-scale production

- Select the right system—matching capacity, automation, and ancillary equipment to your goals

- Optimize your investment—balancing CAPEX with long-term OPEX for maximum ROI

Contact us today via our Contact Form to discuss your specific requirements and receive a tailored proposal. Let KINTEK's expertise in laboratory solutions ensure your pyrolysis project is a success from start to finish.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- Which lab grown diamond process is best? Focus on Quality, Not the Method

- What temperature is heat treatment of aluminium? Achieve Precise Material Properties for Your Alloy

- What is sputtering in simple terms? A Guide to High-Quality Thin Film Deposition

- At what temperature do terpenes evaporate? Unlock the Full Flavor and Effects of Your Cannabis

- What temperature do you heat treat a furnace? It's All About Your Material and Goal

- How to select the best rotary vane pump for specific needs? Match Your Application's Requirements

- Do cannabinoids evaporate? How to Preserve Potency and Prevent Degradation

- What is the distillate extraction method? Achieve Peak Purity in Cannabis Concentrates