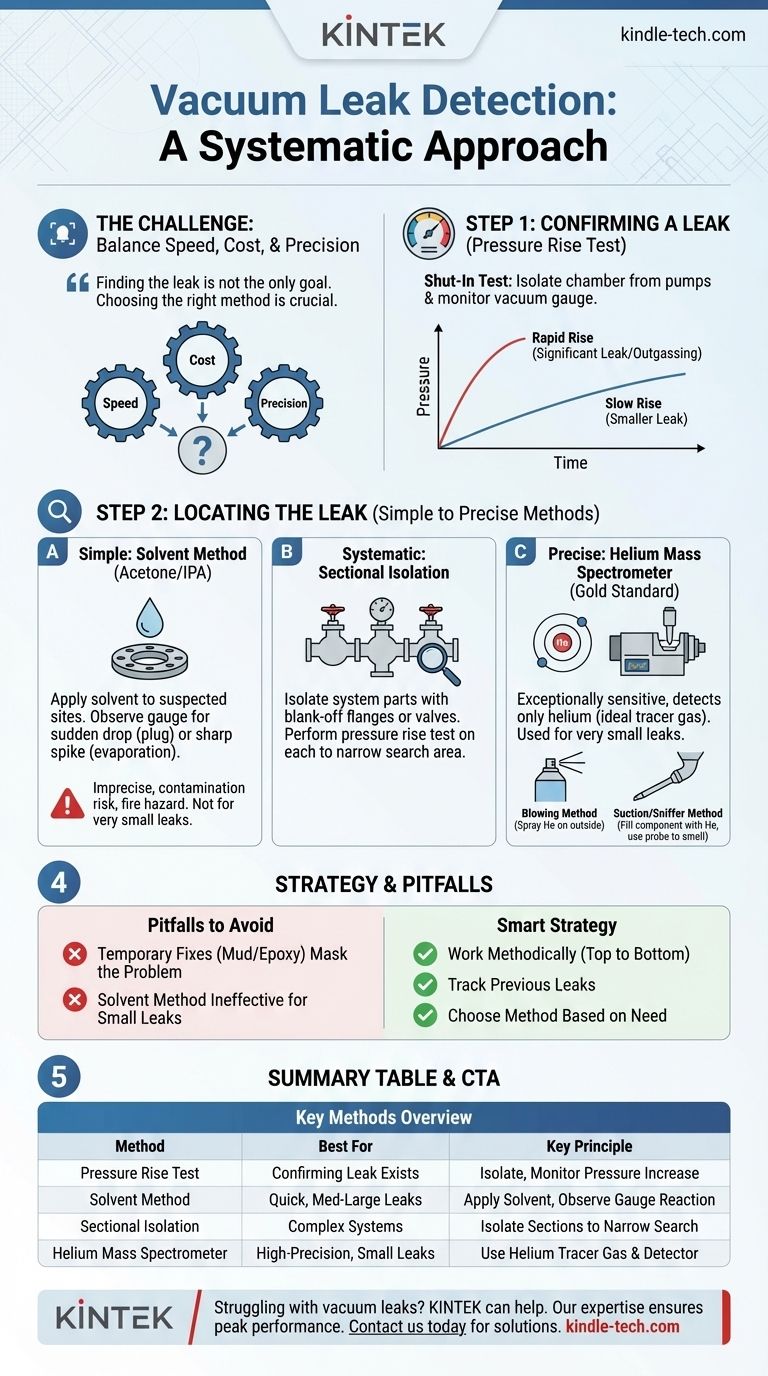

Detecting a vacuum leak requires a systematic approach, ranging from simple pressure tests to the use of highly sensitive equipment. The most common methods involve observing pressure changes in an isolated system, applying a test substance like a solvent to suspected leak points and watching for a gauge reaction, or using a tracer gas like helium with a mass spectrometer for high-precision detection.

The core challenge in vacuum leak detection is not simply finding the leak, but choosing a method with the right balance of speed, cost, and precision for your specific system. While simple methods can identify large leaks, only a systematic approach using a tracer gas can definitively locate the small leaks that degrade high-vacuum performance.

The First Step: Confirming a Leak Exists

Before you begin the time-consuming process of locating a leak, you must first confirm one is actually present. A rising pressure level in your chamber is not always caused by an external leak.

The Pressure Rise Test (Shut-In Test)

The most fundamental diagnostic is the pressure rise test. This test helps determine the overall leak-tightness of your system.

The process involves evacuating the chamber to its normal operating pressure, then closing the high-vacuum valve to isolate the chamber from the pumps.

You then monitor the vacuum gauge over time. A rapid rise in pressure strongly indicates a significant leak or severe outgassing from materials inside the chamber. A slow, steady rise points to a smaller leak or less severe outgassing.

Locating the Leak: From Simple to Precise Methods

Once a leak is confirmed, you can proceed with methods to pinpoint its exact location. These range from quick, low-cost techniques to highly accurate but more complex procedures.

The Solvent Method (Acetone or Isopropyl Alcohol)

This is a common, low-tech method for finding medium-to-large leaks. It relies on a liquid's ability to temporarily plug a leak or cause a pressure change.

By carefully applying a small amount of a volatile solvent, such as acetone or isopropyl alcohol, to a suspected leak site (like a weld or flange), the liquid is drawn into the opening by the vacuum.

This can cause one of two reactions on your vacuum gauge: a sudden drop in pressure as the liquid temporarily seals the orifice, or a sharp spike in pressure as the solvent enters the chamber and rapidly evaporates. This method is fast but lacks precision and can introduce contaminants.

The Sectional Isolation Method

For complex systems with many components, trying to find a leak across the entire assembly is inefficient. A better approach is to isolate sections to narrow the search area.

Using blank-off flanges or by closing valves, you can systematically block off different parts of the vacuum system.

By performing a pressure rise test on each isolated section, you can quickly determine which part of the system contains the leak, allowing you to focus your more precise detection efforts there.

The Helium Mass Spectrometer: The Gold Standard

For high-vacuum applications, a helium mass spectrometer is the definitive tool for leak detection. It is exceptionally sensitive and can locate leaks far too small to be found with other methods.

This device works by connecting a specialized detector to the vacuum system that is tuned to detect only helium atoms. Because helium is a small, inert, and uncommon atom in the atmosphere, it makes an ideal tracer gas.

There are two primary techniques for using a helium detector:

- The Blowing Method: The system is evacuated, and a fine stream of helium gas is sprayed over suspected leak sites on the outside. If a leak is present, the helium is drawn in and immediately registered by the spectrometer, confirming the location.

- The Suction/Sniffer Method: This is used when an object cannot be evacuated. The component is filled with a helium/air mixture under slight pressure. A "sniffer" probe connected to the detector is then passed over the outside of the component to "smell" for any escaping helium.

Understanding the Trade-offs and Pitfalls

Choosing the right method requires understanding the limitations of each. An incorrect approach can waste time or, worse, hide the problem.

The Danger of Temporary Fixes

Applying vacuum mud, epoxy, or external sealing compounds over a suspected leak is an emergency measure, not a solution.

While it may temporarily stop a leak, it makes future, proper leak detection nearly impossible in that area. This approach masks the root cause and can lead to more significant downtime later.

Limitations of Simpler Methods

The solvent method is imprecise, can introduce contamination into your vacuum system, and poses a fire hazard. It is ineffective for the very small leaks that often plague high-vacuum systems.

A pressure rise test is a crucial first step, but it cannot distinguish between a "real leak" (gas entering from the atmosphere) and "virtual leak" (gas trapped inside the chamber, also known as outgassing).

The Need for a Systematic Approach

Randomly spraying helium across a large system is inefficient. The most effective strategy is to work methodically. Start at the highest point of the chamber and slowly work your way down, allowing gravity to carry the helium over the surfaces below. Tracking the locations of previous leaks can also help focus your efforts during routine maintenance.

Choosing the Right Detection Strategy

The best method depends on your system's required vacuum level and the urgency of the repair.

- If you need a quick check for a large leak: Start with a pressure rise test, followed by the targeted application of a solvent like isopropyl alcohol on obvious points of failure like seals and flanges.

- If you are troubleshooting a complex system: Use the sectional isolation method with blank-off flanges to narrow down the problem area before applying a more precise technique.

- If you require absolute certainty for a high-vacuum system: A helium mass spectrometer is the only tool that can reliably and precisely locate the small, performance-degrading leaks that matter most.

A systematic approach transforms leak detection from a frustrating hunt into a manageable diagnostic process.

Summary Table:

| Method | Best For | Key Principle |

|---|---|---|

| Pressure Rise Test | Confirming a leak exists | Isolate chamber, monitor pressure increase over time |

| Solvent Method (Acetone/IPA) | Quick identification of medium-to-large leaks | Apply solvent; observe gauge for pressure drop or spike |

| Sectional Isolation | Complex systems with multiple components | Isolate sections with valves/flanges to narrow search area |

| Helium Mass Spectrometer | High-precision detection of small leaks | Use helium as tracer gas; detect with specialized spectrometer |

Struggling with vacuum leaks? KINTEK can help. Our expertise in lab equipment and consumables ensures your vacuum systems operate at peak performance. Whether you need precise leak detection solutions or reliable maintenance support, we provide the tools and knowledge to minimize downtime and maximize efficiency. Contact us today to discuss how we can enhance your laboratory's vacuum integrity and workflow.

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- Why is coating thickness important? Achieve Optimal Performance and Cost Control

- What is the significance of compression set? Predict Material Failure and Ensure Long-Term Reliability

- What are the advantages of using PTFE filters for ionic component analysis? Ensure Accurate Sample Quantification

- What is the water content of pyrolysis oil? A Key Factor in Bio-Oil Quality and Use

- What is a filter tester? A Guide to Measuring Filtration Efficiency & Performance